Raw Material Pretreatment: Where Transformation Begins

On the bio organic fertilizer production line, everything starts with the remarkable transformation of organic waste. Livestock manure, crop straw, and food processing byproducts – these “misplaced resources” – are finely processed by grinders into uniform particles suitable for fermentation. These materials are then scientifically mixed with water and fermentation agents, like concocting a magical “activation potion” to create the perfect microbial environment for subsequent processes.

Fermentation Process: A Microbial Feast

The pretreated materials enter fermentation equipment (fermentation tanks or silos), initiating a microbe-led “celebration”. In the organic fertilizer line, this stage is truly the soul of the operation. Through regular turning and precise control of temperature, humidity, and oxygen levels, organic matter is efficiently decomposed at high temperatures, harmful pathogens are eliminated, and the materials ultimately transform into nutrient-rich organic fertilizer substrates.

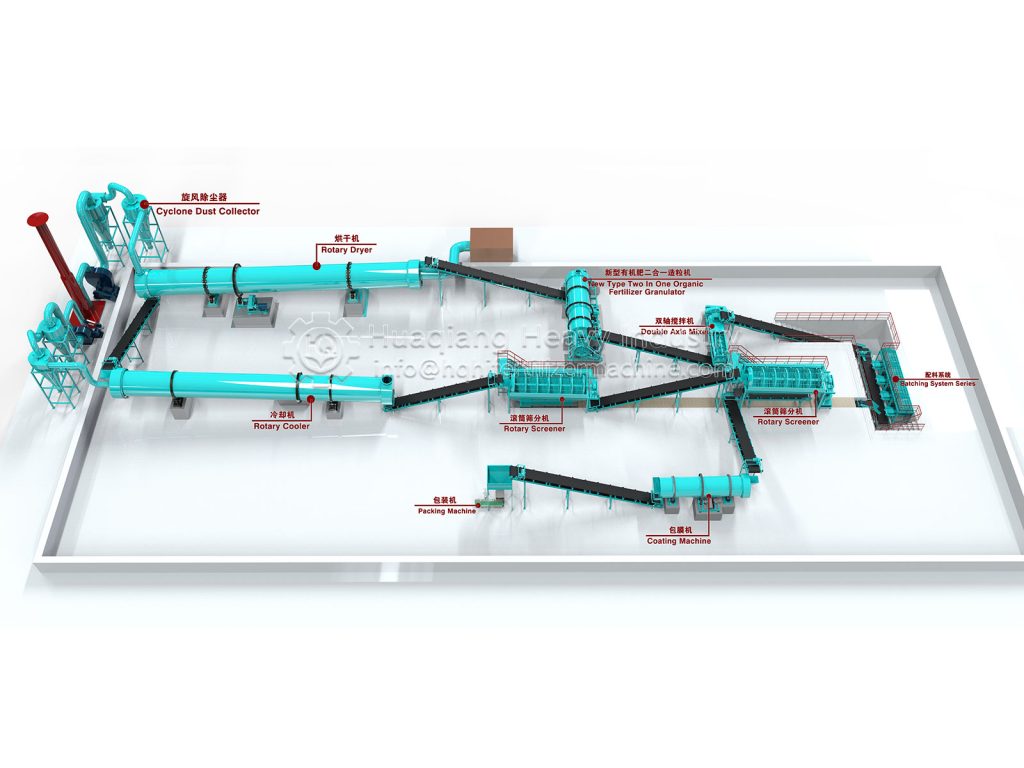

Precision Processing: Crafting Perfect Pellets

After fermentation, the materials undergo drying to remove excess moisture before entering the crucial stage of bio organic fertilizer production – granulation. Various types of granulators shape the loose materials into uniform pellets, both aesthetically pleasing and convenient for transportation. The screening machines act as strict quality inspectors, ensuring every fertilizer pellet meets standards, with oversized or undersized particles being “recycled”.

Quality Enhancement: From Adequate to Excellent

In the final stage of a modern bio organic fertilizer production line, qualified pellets are uniformly mixed with additives like microbial agents and trace elements, as if donning “nutrient armor” for the fertilizer. Automatic packaging machines dress these “black gold” particles in neat packaging, while rigorous quality testing ensures every bag meets national standards, providing reliable support for green agriculture.