In the production of NPK fertilizers, the energy consumption of fertilizer crushers is influenced by various factors, including the physical properties of the materials as well as the operation and design of the equipment. Understanding these influencing factors can help optimize the crushing process and reduce energy consumption. Here are some of the main influencing factors:

Material hardness and toughness: The higher the hardness and toughness of the material, the more energy is required for crushing. Materials with excessively high hardness can significantly increase the energy consumption of the crusher, so when choosing a crusher, it is necessary to consider the hardness characteristics of the material.

Material humidity: Materials with high humidity are prone to adhere to the interior of the equipment during the crushing process, forming bonds or clumps, which increases the difficulty and energy consumption of crushing. Pre drying materials can effectively reduce energy consumption.

Feed particle size: The larger the feed particle size, the more energy is required to grind it to the desired particle size. Pre screening or pre crushing can reduce the particle size of the feed and lower energy consumption.

Target granularity: Crushing to finer granularity requires more energy. Reasonably setting target granularity based on production needs to avoid excessive crushing can effectively save energy.

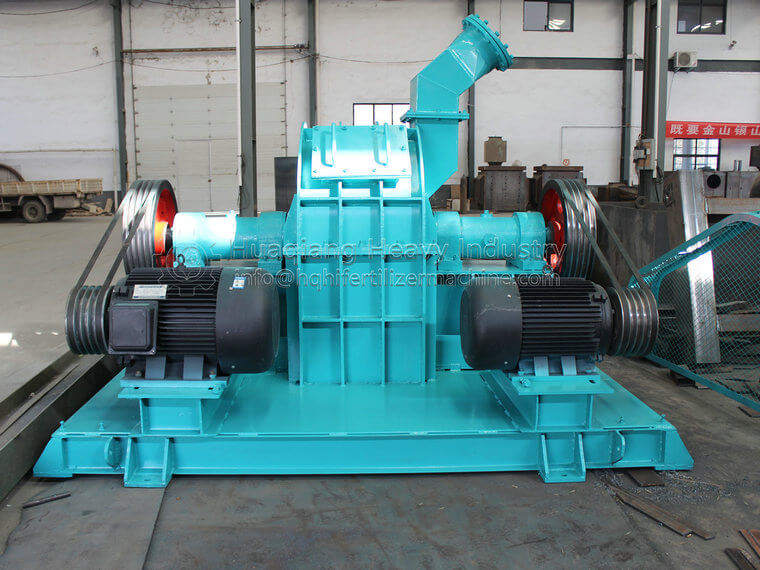

Types and designs of fertilizer crushers: Different types of crushers have different energy conversion efficiencies. For example, there is a significant difference in energy consumption between hammer crushers and cage crushers when processing materials with different characteristics. Optimizing equipment design, such as improving transmission efficiency, reducing friction losses, and also reducing energy consumption.

Operating parameters: including the speed of the fertilizer crushers, feed rate, equipment load, etc. Excessive speed or load can increase energy consumption, and reasonable operating parameter settings can optimize energy use.

Maintenance status: The wear and maintenance of equipment have a significant impact on energy consumption. Severely worn components will increase friction losses, leading to increased energy consumption. Regular maintenance and timely replacement of worn parts can maintain the optimal operating condition of the equipment and reduce energy consumption.

Environmental temperature: Higher environmental temperatures may affect the cooling efficiency of equipment and increase energy consumption. Keeping the equipment running at an appropriate temperature can reduce energy consumption.

By controlling and optimizing the above factors, it is possible to effectively reduce energy consumption in NPK fertilizer production while ensuring the crushing effect of the fertilizer crushers, achieving a dual improvement in economic and environmental benefits.