Organic fertilizer production is a systematic process that converts organic wastes into nutrient-rich, stable soil amendments through a combination of biological decomposition and physical processing. This sustainable process not only addresses the problem of organic waste disposal but also provides farmers with an eco-friendly alternative to chemical fertilizers. The entire production line consists of sequential stages, with key focuses on microbial digestion during composting and physical transformation in subsequent processing. Below is a detailed breakdown of the core process of organic fertilizer production.

The first stage is raw material preparation, which lays the foundation for high-quality organic fertilizer. The main raw materials include various organic materials such as animal manure (cow dung, chicken manure, etc.), crop residues (straw, corn stover, etc.), and food waste. These raw materials are collected and sorted first to remove impurities like stones, plastics, and metal fragments that may affect the fermentation process and final product quality. For bulky materials such as crop straws or oil palm empty fruit bunches, preliminary crushing is often required to increase the contact area between the materials and microorganisms, thereby improving fermentation efficiency. At this stage, the key is to ensure the purity of raw materials and lay the groundwork for the subsequent control of moisture and carbon-nitrogen ratio.

Composting (fermentation) is the core stage of organic fertilizer production, relying on microbial activity to decompose organic matter. During this process, the moisture content of the piled materials is strictly controlled at around 50-60%—a level that provides sufficient water for microbial metabolism while avoiding oxygen deficiency caused by excessive moisture. The carbon-nitrogen ratio (C/N) is also a crucial parameter, which needs to be adjusted to an appropriate range (usually 25:1 to 30:1) by mixing high-carbon materials (such as straw) and high-nitrogen materials (such as animal manure) to meet the nutritional needs of microorganisms. To maintain aerobic conditions, the compost pile is turned regularly. This aeration not only supplies oxygen to aerobic microorganisms but also helps control the temperature of the pile, which typically reaches 60-70°C. This high-temperature environment can effectively kill pathogens, weed seeds, and insect eggs in the raw materials, while promoting the decomposition of organic matter into stable humus and stabilizing nutrients.

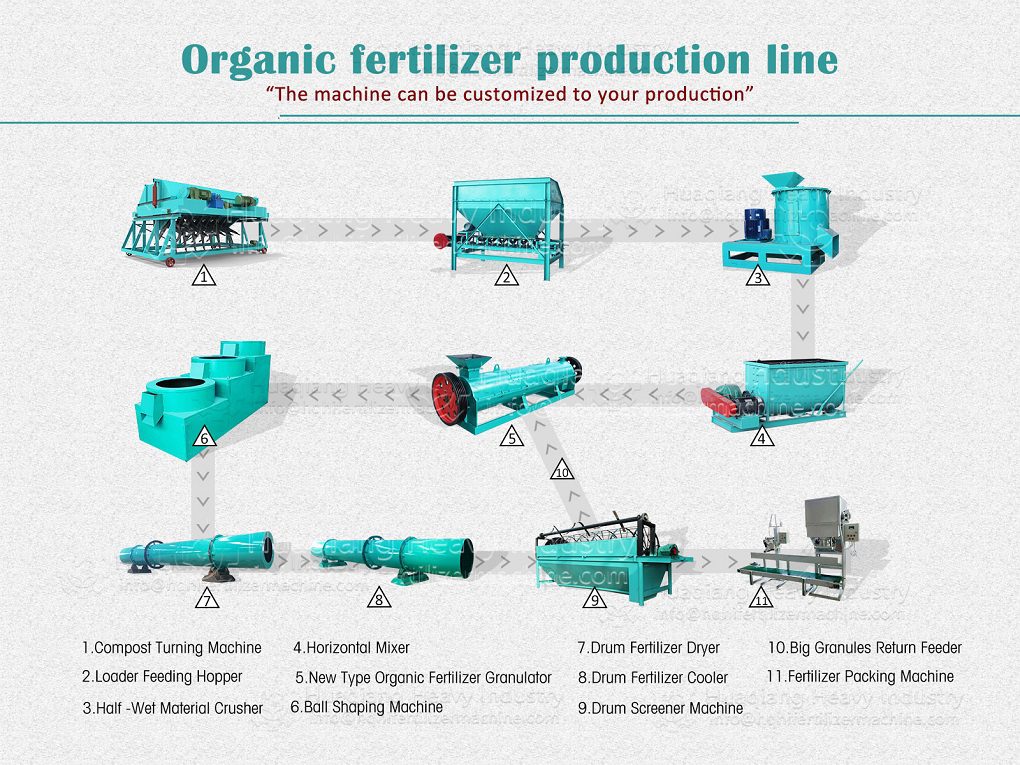

After composting, the matured compost enters the deep processing stage. The first step is crushing: the composted material is ground into a uniform and finer powder to eliminate agglomerates, ensuring the uniformity of subsequent mixing. Next is mixing, where the crushed compost is blended with other nutrients (such as trace elements) or additives (such as biological bacterial agents) to enhance the fertilizer effect and meet the needs of different crops and soils.

Granulation is an optional but common step. Special granulators, usually wet granulators, are used to form the mixed powder into granules. Granulation improves the convenience of transportation, storage, and application, and reduces dust pollution. After granulation, the granules need to be dried using a rotary hot air dryer to reduce moisture content, which prevents caking and improves granule strength. The drying temperature must be strictly controlled to avoid scorching and damaging the effective components. Subsequently, the hot granules are rapidly cooled by fans to prevent softening and reabsorption of moisture. The cooled products then go through screening to separate qualified granules from oversized or undersized ones, which can be recycled back to the crushing or granulation stage. Coating is another optional step, where a coating is applied to enhance brightness, roundness, and moisture resistance for better storage. Finally, the finished organic fertilizer is weighed and bagged for sale. This multi-step process ensures that the final product is stable, nutrient-rich, and easy for farmers to apply.

Building a Modern Organic Fertilizer Factory

In conclusion, the transformation of organic waste into a valuable fertilizer is a carefully orchestrated process that combines natural biology with industrial precision. This journey from raw waste to finished product forms the backbone of a modern organic fertilizer production line.

The process begins with efficient organic fertilizer fermentation, optimized by advanced fermentation composting turning technology. The resulting mature compost then enters the organic fertilizer production granulation stage. Here, manufacturers can choose from a suite of specialized fertilizer granulator technologies. Options include traditional drum granulation, a dedicated organic fertilizer disc granulation production line, or more innovative solutions like a new type two in one organic fertilizer granulator or a versatile flat die pelleting machine. For operations requiring maximum flexibility, an organic fertilizer combined granulation production line can integrate multiple methods. When microbial inoculants are added, this entire system evolves into a sophisticated bio organic fertilizer production line, capable of producing a diverse range of high-quality, sustainable soil amendments.

Ultimately, this integrated approach demonstrates how technological innovation elevates a natural process, creating efficient systems that support both agricultural productivity and environmental stewardship on a global scale.