Small-scale organic fertilizer production line is mainly used for livestock manure organic fertilizer processing production line project. It is characterized by low overall investment price, low cost and low technical requirements, which is suitable for large-scale planting and breeding enterprises and small fertilizer plants.

Finally, according to the desired form of organic fertilizer, it can be divided into powder organic fertilizer and granular organic fertilizer. Different forms of fertilizer require different production line equipment. Because the configuration, specification and required equipment of organic fertilizer production line are different, the price will also affect the quotation.

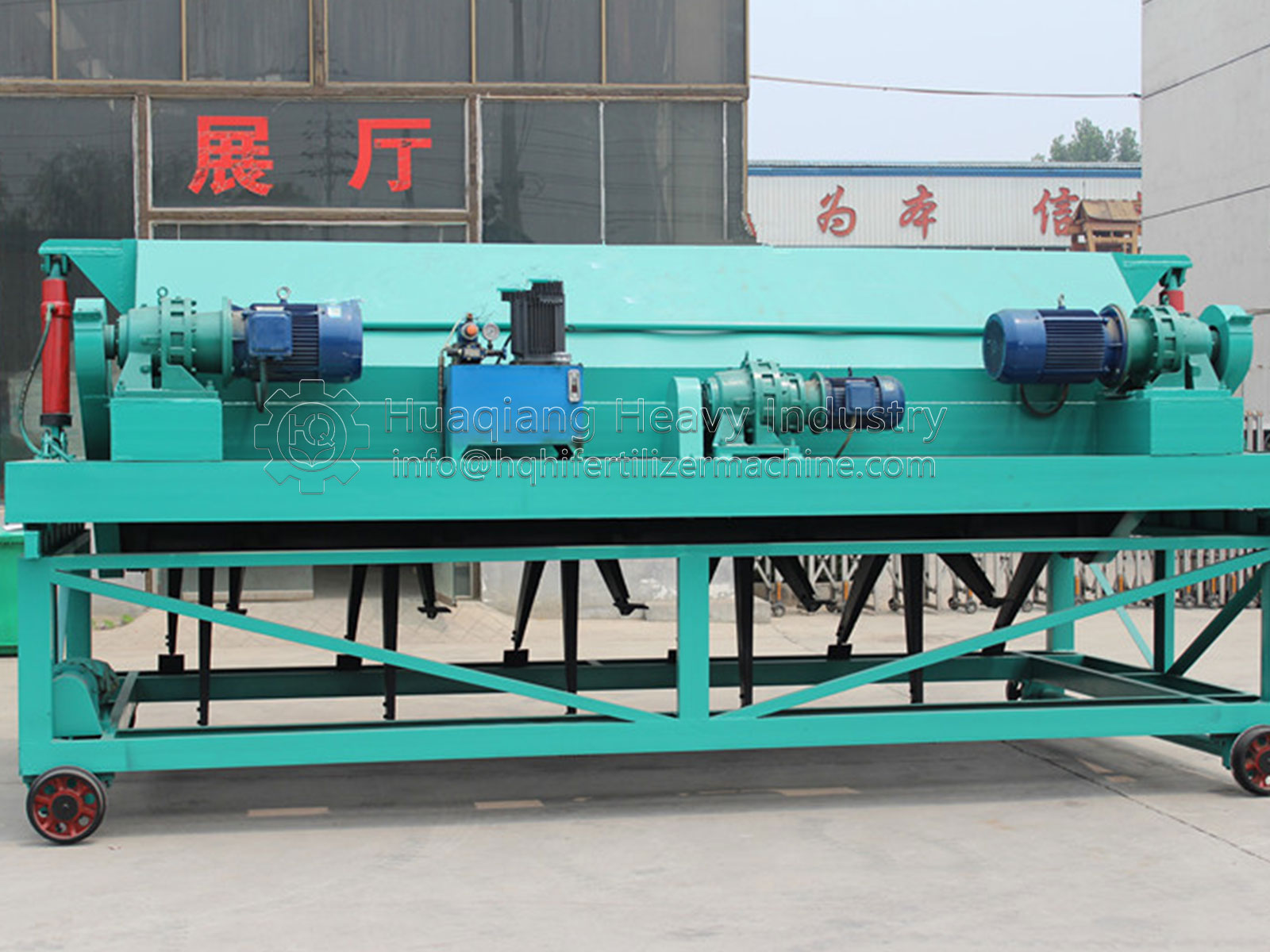

The production of powdery organic fertilizer is based on the fine crushing treatment after the fermentation of organic fertilizer. The required equipment: fermentation tipper, forklift silo, semi-wet material crusher, drum screening machine, automatic packaging scale. The price of the smallest powdered organic fertilizer production equipment is about 100000 yuan.

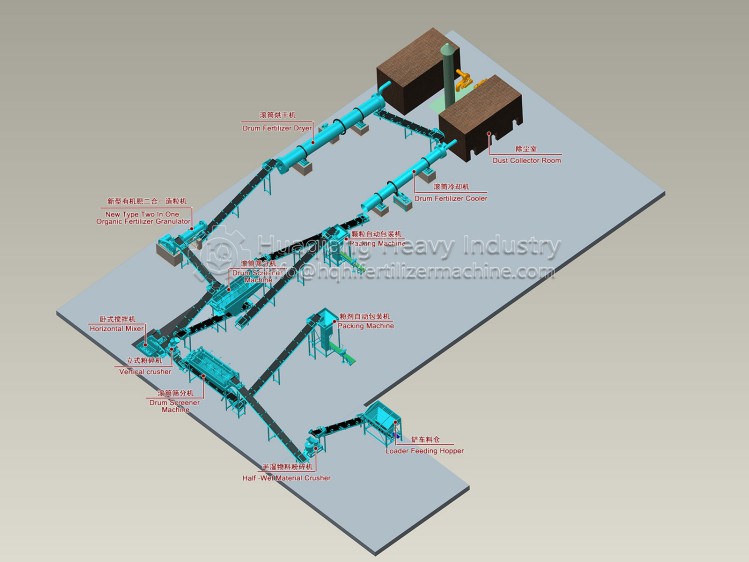

At present, the production process of granular organic fertilizer is the most complex, and it is also based on the continuous fermentation process and the wages of powdered organic fertilizer. Therefore, the equipment required is also relatively comprehensive, including fermentation tipper, forklift silo, semi-wet material crusher, horizontal mixer, stirrer granulator, rotary dryer, rotary cooler, drum screening machine, coating machine, and automatic packaging machine. Dynamic batching scale is also required in case of special process requirements. The price of the complete set of equipment with the minimum specification is about 200000 yuan.

In terms of production scale alone, the small-scale organic fertilizer processing plant takes the annual output of 5000 tons to 10000 tons as the standard, which is also the most selected production line scale for investors who are new to the industry. The complete set of equipment is composed of many kinds of equipment. Their type selection, specification and quantity directly affect the final price of the production line. That is to say, the price of the production line with the same output is not the same, even very different. Under the same output, the powdery production line is much cheaper than the granular production line, but the corresponding powdery finished organic fertilizer is not as expensive and profitable as the granular organic fertilizer. Finally, it is suggested that you should pay attention to two points: first, raw material procurement; The second is marketing. These two aspects are very important. In short, the same sentence: entrepreneurship is risky, and investment needs to be cautious.