At present, there are several processes in the manufacturing of composite (mixed) fertilizers in China:

1. Production Technology of Mixing Method

This process is the simplest compound fertilizer production process in China. The compound fertilizer produced by this process or method is called blended fertilizer or BB fertilizer. Its characteristics are simple process, flexible ratio, and the raw material fertilizer still remains in its original state, which is relatively intuitive, and the nutrient ratio is easy to adjust. However, its disadvantage is that fertilizers are prone to separation of nitrogen, phosphorus, and potassium fertilizers during transportation and application, and fertilizers are prone to moisture absorption and agglomeration. At present, most BB fertilizer formulas on the market are of high nitrogen, high potassium, and high concentration types, lacking medium and trace elements.

2. Production Technology of Dry Powder Physical Agglomeration Method

The physical granulation technology of dry powder is to select several fertilizer raw materials, dry powder, for metering and mixing according to needs, and use binders as binders to form particles in the fertilizer granulation machine. The granulation of dry powder mixture needs to be heated, and the liquid phase amount needs to be increased by adding water or steam. Then, under rolling conditions, it agglomerates into composite fertilizer particles with a certain particle size in a disc or drum. At present, in this type of process, acid (especially phosphoric acid) and ammonia are usually added to increase the liquid content, and heat is provided by the chemical reaction that occurs. The ammonium phosphate generated by the reaction of phosphoric acid and ammonia becomes a component of composite fertilizers. The materials inside the granulator should be controlled at the optimal temperature (50-80 ℃) and moisture content (2.5% -7.5%) to achieve suitable granulation conditions. The compound fertilizer produced by this process has no substantial difference from the BB fertilizer mentioned above in terms of nitrogen, phosphorus, and potassium composition. Just consolidate the smaller particles (powder) into particles. So it can also be said that the compound fertilizer produced by this process is deeply processed BB fertilizer.

3. Slurry production process technology

The slurry process is the product of the reaction of sulfuric acid, nitric acid, phosphoric acid, or some mixed acid with ammonia (sometimes also the product of the reaction of acid with phosphate rock powder), which is a nitrogen phosphorus slurry. Then, potassium salt is added to the slurry or directly added to the granulator, and the nitrogen phosphorus slurry is sprayed into the fertilizer granulator. Then, it reacts with potassium salt at high temperature to produce a nitrogen phosphorus potassium ternary compound fertilizer. The nutrients in the compound fertilizer produced by this process are very uniform, and the nutrient content and proportion in the fertilizer particles are completely consistent. The physical and chemical properties of particles are first-class. The forms of nitrogen in fertilizers include ammonium nitrogen and nitrate nitrogen, so the fertilizer efficiency is better than that of single urea or single ammonium equivalent nitrogen phosphorus potassium fertilizers.

4. High tower granulation technology for producing urea based composite fertilizer

This process is a new one that has emerged in the production of compound fertilizers in China in recent years, namely the high tower urea based compound fertilizer process. It actually involves melting urea, measuring the molten urine and feeding it into a mixer using a melt pump. The heated powdered ammonium phosphate, potassium chloride, and additives (auxiliary materials) are then metered and added to a heater for heating. The preheated material is then fed into the mixer and mixed with the molten urine for reaction, fully mixing to form a highly soluble and flowable additive compound slurry. Then it flows into the rotating nozzle located on the top of the tower by its own gravity, and then spray into droplets. When the droplets fall from the top of the tower, they are in reverse contact with the rising cold air for heat transfer, and crystallize, solidify, and cool into finished particles in the air. The large particles screened out are crushed by a crusher and together with fine powder, they are returned to the heater for recycling.

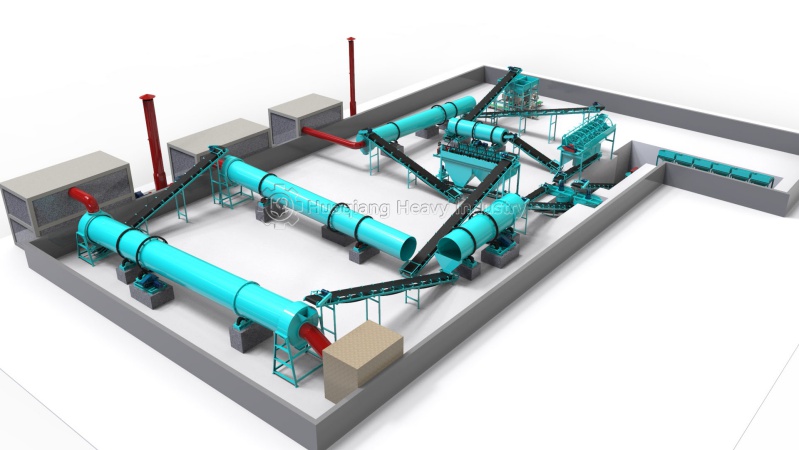

The common granulation processes for compound fertilizers include drum granulation, disc granulation, spray granulation, and tower granulation, each of which has certain advantages.

.jpg)

.jpg)

.jpg)

.jpg)