The granulation process of the entire organic fertilizer production line

Granulation is the core process in organic fertilizer production, which directly affects the physical properties, nutrient release efficiency, and market competitiveness of fertilizers. This article will systematically analyze the complete process of organic fertilizer granulation, covering equipment selection, process parameters, and quality control points.

1、 Pre treatment before granulation

Raw material crushing

After fermentation and maturation, organic materials need to be processed by a semi wet material crusher to crush fiber materials (such as straw and mushroom residue) to a particle size of 3-5mm to ensure granulation flowability.

Key parameters: The moisture content should be controlled at 25% -30%. If it is too high, it is easy to block the mold, and if it is too low, the adhesion is insufficient.

Mixing of ingredients

Add functional excipients (such as humic acid and microbial agents) according to product requirements, and mix evenly (coefficient of variation ≤ 5%) using a dual axis mixer.

Typical case: When producing bio organic fertilizers, microbial agents need to be added in a low temperature (<40 ℃) environment to avoid loss of activity.

2、 Core granulation process

Disc granulator (suitable for small and medium-sized production capacity)

Working principle: The tilted rotating disk (with an inclination angle of 35 ° -55 °) causes the powder to roll and bond into particles under the action of centrifugal force.

Technical points:

Spray an appropriate amount of water or binder (such as lignosulfonate) to promote molding;

The particle diameter is adjusted by disc rotation speed and inclination angle (usually 2-6mm).

Advantages: Low equipment investment (about 50000 to 80000 yuan per unit), suitable for production lines with an annual output of less than 5000 tons.

Drum granulator (suitable for large-scale production)

Working principle: The material forms particles through agglomeration in the rotating drum, and is assisted by hot air for drying.

Technical points:

The rotation speed of the cylinder is 8-15r/min, and the filling rate is controlled at 20% -30%;

It can simultaneously complete granulation and pre drying, with a production capacity of 10-20 tons/hour.

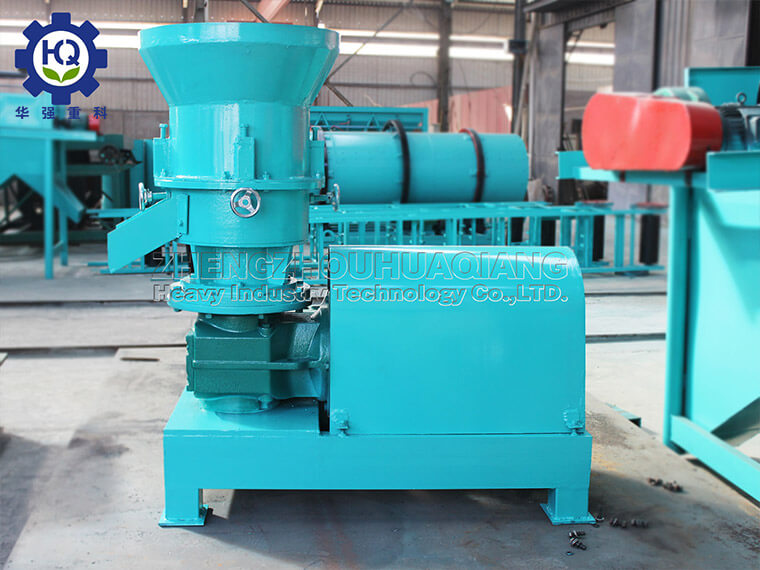

Roll squeezing granulator (low-energy solution)

Applicable scenario: Powdered organic fertilizers with low particle strength requirements can be directly formed without drying.

Advantages: The power consumption is only one-third of that of disc granulation, but the surface smoothness of the particles is poor.

3、 Post processing procedure

Drying and dehydration

Use a drum dryer (hot air temperature 80-120 ℃) to reduce the moisture content of the particles from 30% to ≤ 15% to avoid storage mold.

Energy saving design: Some production lines utilize fermentation waste heat to provide heat sources, reducing energy consumption by more than 20%.

Cooling screening

The vibration cooling machine lowers the particle temperature from 60 ℃ to room temperature, and at the same time, it is classified through multiple layers of sieves (such as 4mm and 6mm aperture) to remove powder and oversized particles.

Encapsulation treatment (optional)

Spray anti caking agents (such as mineral oil) or slow-release film materials on the surface of particles to enhance product added value.

4、 Key points of quality control

Particle strength: ≥ 15N/particle (to avoid transportation breakage);

Molding rate: Disc granulation ≥ 85%, drum granulation ≥ 90%;

Survival rate of microbial agent (bio fertilizer): The granulation temperature should be ≤ 50 ℃, and the survival rate should be>80%.

5、 Innovative technology application

Intelligent control system: Real time monitoring of the humidity and temperature of the granulation disk through sensors, automatic adjustment of water spray volume and speed.

Composite granulation process: organic-inorganic fertilizer mixed granulation, with both fast acting and long-lasting characteristics.

Organic fertilizer granulation is a key link in balancing physical properties and production costs. Enterprises need to choose suitable processes based on the characteristics of raw materials (viscosity, fiber content) and product positioning (ordinary organic fertilizer/high-end biological fertilizer). In the future, with the development of technologies such as low-temperature granulation and precise coating, organic fertilizer particles will continue to upgrade towards functionalization and intelligence.

.jpg)