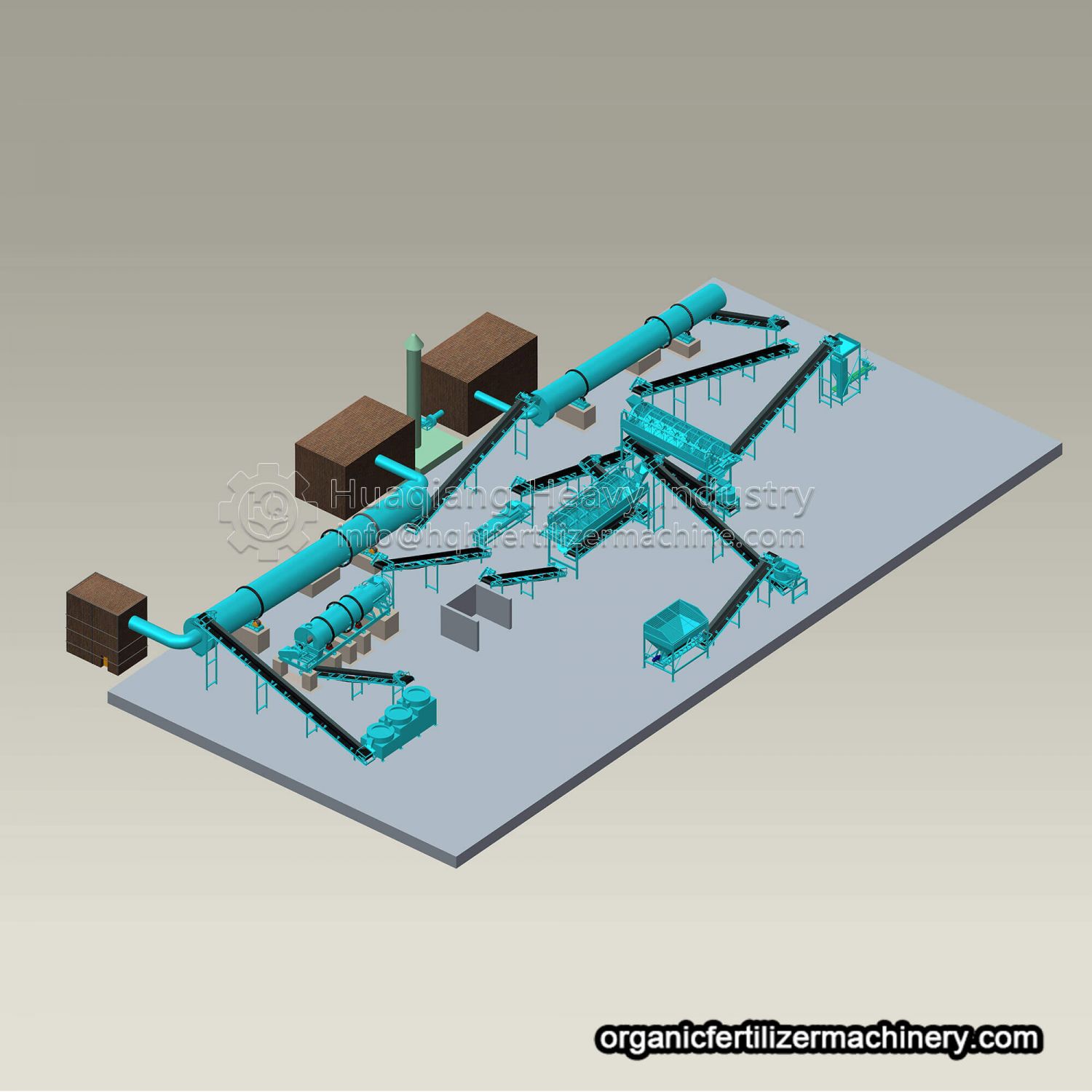

Production technology and operation effect of cow dung organic fertilizer production line

An organic fertilizer production line can not only meet the local fertilizer demand, but also meet the needs of the surrounding market. Do you know the working principle and fertilizer granulation process of the organic fertilizer production line? Let me talk about it today.

1. Adopt trough biological fermentation. According to your production scale, you need to build four fermentation tanks with a width of 3 meters and a length of 50 meters. It can achieve the purpose of water regulation and uniform mixing, which can save a lot of land and a lot of labor, and can achieve the purpose of fully decomposing.

2. A forklift uses a shovel to move the high-grade fermented organic fertilizer that has been turned to the fermentation tank to the semi-finished product stacking area, which is convenient for handling the high-grade fermented organic fertilizer that is thrown by the dumper every day and is discharged out of the tank in time.

3. The sieving machine sifts the fermented organic fertilizer, and detects the large pieces and debris inside, which is convenient for the next step of crushing and packaging.

4. The pulverizer sorts out the large debris and stones in the sifted organic fertilizer and smashes them, so that it is beautiful and can ensure the quality of the product.

5. The premixer will premix the sieved and crushed organic fertilizer to ensure the stability of the product quality, and at the same time, it can also play a mixing role when adding fertilizers and trace elements for the production of special fertilizers and various compound fertilizers.

6. After the packaging machine is evenly premixed, the organic fertilizer will be granulated by organic fertilizer granulator if needed, or directly packaged and sold if no granulation is required.

The above is the knowledge shared by the organic fertilizer production line manufacturers. I hope it will be helpful to you. If you want to know more, please contact us as soon as possible.