NPK Fertilizer Line: Why It Stands Out?

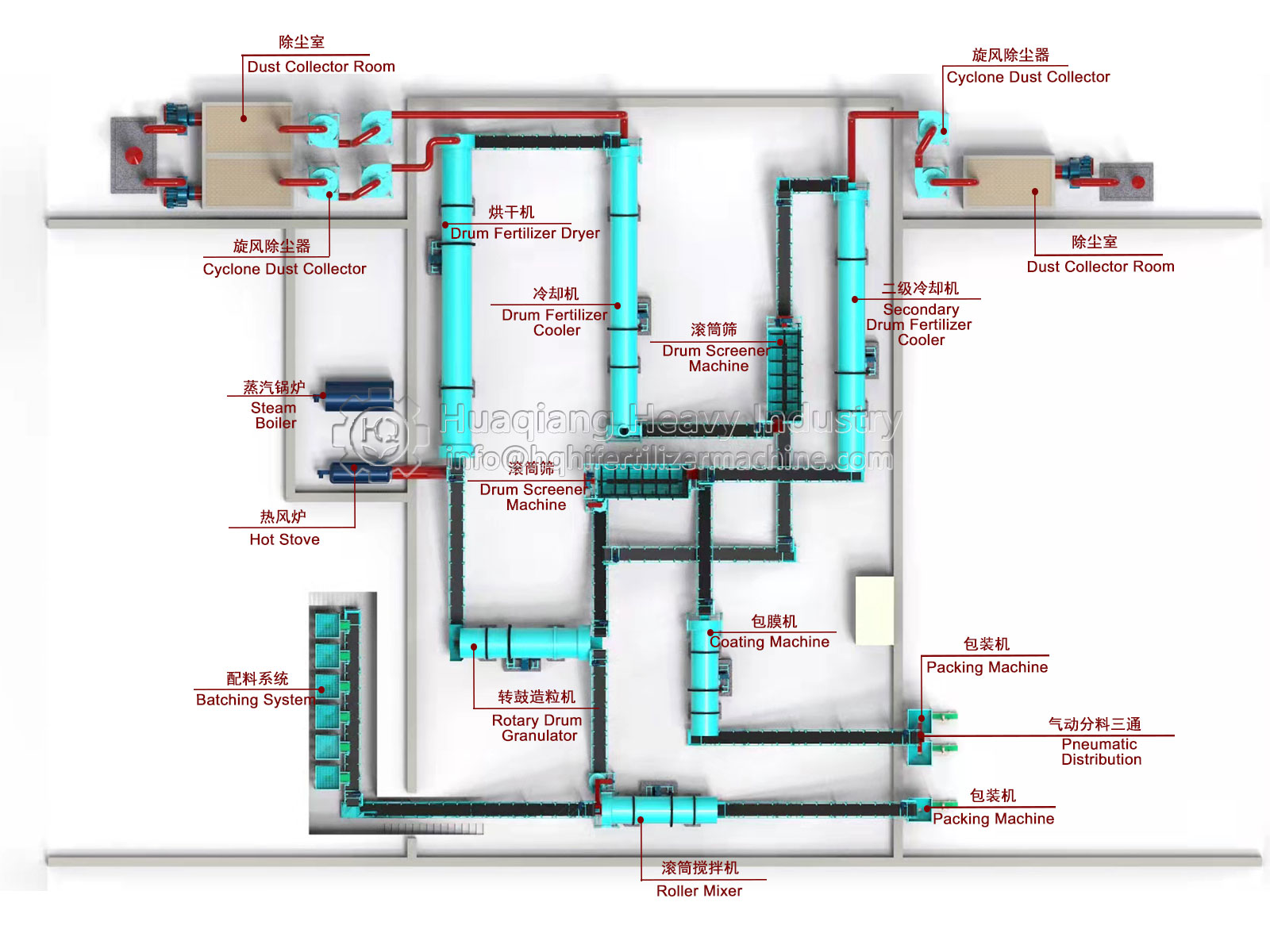

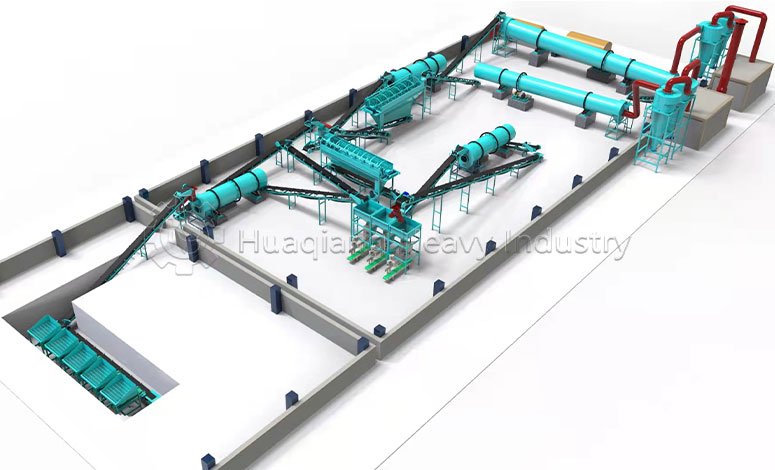

In the era of precision agriculture, the modern NPK fertilizer production line serves as a master nutritionist, expertly formulating the perfect blend of nitrogen, phosphorus, and potassium through sophisticated equipment like the precision NPK blending machine. This advanced manufacturing system works in harmony with the organic fertilizer production line to create comprehensive nutrient solutions for modern farming. At the heart of both systems operates the versatile fertilizer granulator, particularly the efficient disc granulator, which transforms blended powders into uniform, easy-to-apply granules. The complete disc granulation production line ensures consistent particle size and nutrient distribution, revolutionizing agricultural productivity worldwide with exceptional performance and reliable operation that meets the exacting demands of precision agriculture.

Outstanding Performance: Perfect Fusion of Stability and Efficiency

Reliable Operation

With precision engineering and premium materials, the production line maintains exceptional stability during continuous operation, significantly reducing downtime and ensuring consistent output.

Easy Maintenance

Modular design and intelligent diagnostic systems simplify routine maintenance and troubleshooting, substantially lowering operational costs and technical barriers.

Superior Pelletizing Rate

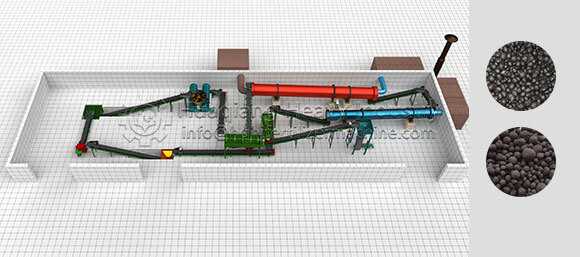

Advanced granulation technology ensures uniform, robust fertilizer pellets, enhancing both product appearance and application effectiveness.

Particularly noteworthy is the production line’s excellence in biological agent incorporation. Through precise temperature control and mixing processes, it effectively preserves beneficial microorganism viability, providing reliable technical support for high-quality bio-organic compound fertilizer production.

Raw Material Versatility: The True “Adaptable” Expert

The production line’s strength lies in its remarkable material adaptability:

- Processes various nitrogen sources including urea, ammonium sulfate, and ammonium chloride

- Compatible with different grades of phosphate rock powder and potassium salts

- Supports combination of organic and inorganic raw materials

- Adapts to raw materials with varying moisture content and particle size

Quality Assurance: Perfect Transformation from Raw Materials to Finished Products

Every process stage undergoes meticulous design and strict control. From precise raw material proportioning to controlled mixing and granulation, through to final packaging and storage, the entire production process reflects an uncompromising pursuit of quality. The resulting compound fertilizers feature uniform nutrient distribution, firm granules, excellent solubility, and optimal soil compatibility.

The NPK fertilizer production line represents not only the technical achievement of modern agricultural chemistry but also a vital force driving sustainable agricultural development. Through its stable performance, efficient output, and exceptional product quality, it’s helping farmers worldwide produce better crops in more environmentally friendly and economical ways, making indispensable contributions to global food security.