From Raw Materials to Finished Products: Exploring the Precision Process Journey of NPK Fertilizer Granulation

The Perfect Performance of Precision Process

The NPK fertilizer granulation process resembles a carefully orchestrated industrial symphony, with multiple interconnected processes collectively performing the magnificent transformation from raw materials to efficient fertilizers. At the heart of the complete npk fertilizer production line, specialized equipment like the precision npk blending machine and versatile fertilizer granulator work in perfect harmony. The disc granulator serves as a centerpiece in many disc granulation production line setups, creating uniform nutrient-rich pellets.

The brilliance of this sophisticated npk fertilizer line lies not only in physical processing but in deep optimization of nutritional formulation and particle quality. Each component within the production system contributes to transforming raw materials into premium fertilizers through precisely controlled mechanical and chemical processes that ensure consistent product performance and nutrient availability.

Raw Material Preparation

According to the target fertilizer formula, precisely weigh raw materials such as urea, phosphate fertilizer, and potassium salt to ensure accurate proportion of nutrient elements. Subsequently, process large raw materials into particle sizes suitable for mixing through crushers, laying a solid foundation for subsequent processes.

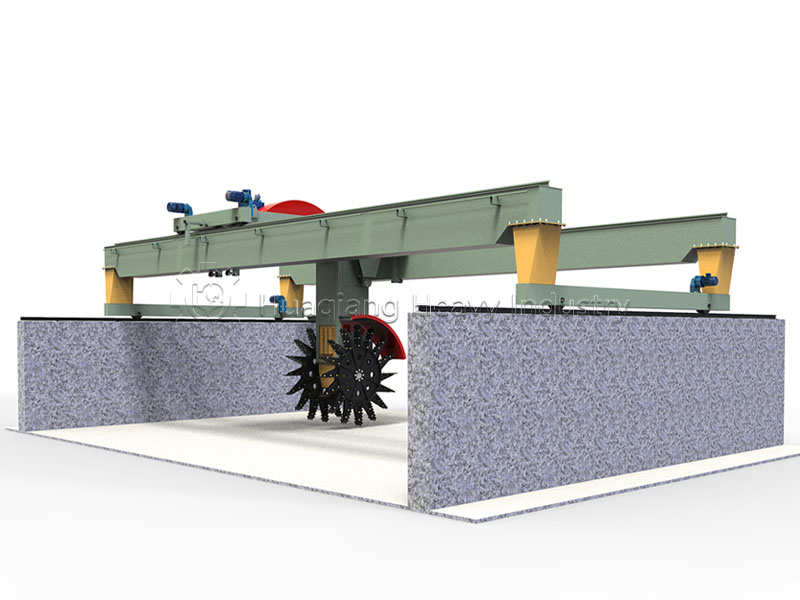

Raw Material Mixing

Feed the proportioned raw materials into dual-shaft paddle mixers or V-shaped mixers to achieve thorough and uniform mixing of raw materials through mechanical force. This step ensures even distribution of various nutrient elements in the fertilizer.

Granulation Forming

Add appropriate amount of water according to granulation needs to bring raw materials to suitable humidity. Then use disc granulators, drum granulators, or extrusion granulators to form mixed materials into particles of specific sizes and shapes through rotation or pressure.

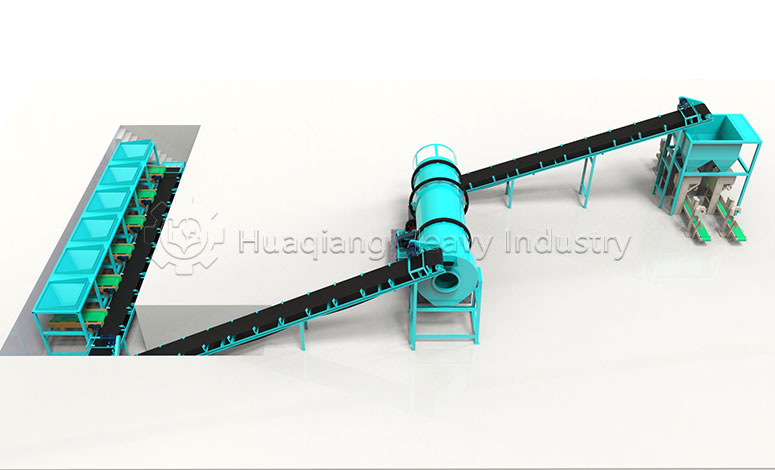

Drying Treatment

Send moist particles into fluidized bed dryers or rotary drum dryers to remove moisture from particles through hot air or other drying media, preventing particle agglomeration during storage and transportation.

Cooling Process

Dried particles have high temperatures and need to be cooled to suitable temperatures through equipment such as cooling drums to prevent high temperatures from affecting fertilizer performance while creating conditions for subsequent processing and packaging.

Screening Selection

Use screening machines to grade and screen cooled particles, selecting high-quality particles that meet particle size requirements. Oversized particles may need regranulation, while undersized particles can be recycled as dust.

Coating Treatment

To enhance fertilizer moisture resistance and control nutrient release rate, some production lines apply coating treatment to qualified particles, wrapping organic or inorganic films on particle surfaces.

Automatic Packaging

Use automatic packaging machines to weigh and package finished fertilizers, forming standardized finished fertilizer bags, making final preparations for storage and transportation.

Intelligent Control

The entire production line is equipped with advanced PLC control systems and automation instruments to monitor and adjust key parameters such as raw material ratio, granulation humidity, and drying temperature in real-time, ensuring production process stability and product quality.

Process Essence: The Art of Precision Control

The core appeal of the NPK fertilizer granulation process lies in its precise control of every production link. From accurate measurement of raw material ratios to fine adjustment of granulation humidity, and strict control of drying temperature, every parameter is carefully designed and optimized. This science-based production process not only ensures the nutritional balance and physical characteristics of fertilizer products but also achieves efficiency and stability in the production process. The introduction of intelligent control systems enables operators to monitor equipment operation status in real-time and adjust process parameters promptly, greatly improving production efficiency and product quality consistency.

Deep Embodiment of Innovative Value

The NPK fertilizer granulation process not only represents technological advancement in fertilizer production but also serves as an important manifestation of modern agricultural technology. Through precise nutritional formulation and standardized production processes, it provides balanced nutritional supply for crops, significantly improves fertilizer utilization efficiency, and reduces environmental pollution. With the deepening promotion of precision agriculture and sustainable development concepts, this efficient and environmentally friendly fertilizer production method will play an increasingly important role in ensuring food security and promoting agricultural modernization. From raw material processing to finished product packaging, every process embodies the wisdom of modern engineering technology, contributing significantly to global agricultural development.

NPK Fertilizer Granulation Process – Nine Precision Steps, Forging Excellent Fertilizer Quality