Ring Die Pelleting Machine: The Industrial Alchemy of Fertilizer

In modern fertilizer production lines, the ring die pelleting machine works like a master magician, miraculously transforming various raw materials into uniform fertilizer pellets. Each step of this industrial magic show contains exquisite process wisdom.

Raw Material Metamorphosis

Organic materials first undergo a 30-45 day fermentation “aging period,” then are ground into 60-100 mesh powder as fine as flour. For compound fertilizer ingredients, NPK nutrients are measured with perfume-maker’s precision, requiring over 90% mixing uniformity and moisture strictly controlled within the golden 8%-15% range.

Conditioning: The Material Spa

Pretreated materials enter the conditioner for a steamy 60-80℃ spa treatment. Moisture is precisely adjusted to 12%-18%, making materials soft and sticky – like well-kneaded dough – perfectly prepared for granulation.

High-Pressure Extrusion: Birth of Pellets

Conditioned materials enter the “pressure chamber” between ring die and rollers, enduring 20-50MPa pressure – equivalent to 200-500kg force on a fingernail-sized area. Under this force, materials transform into uniform columns through precision die holes.

Precision Cutting & Cooling

Freshly extruded columns immediately meet high-speed rotating blades, being cut into 2-10mm pellets with under 0.3mm length variation. These “newborns” then enter cooling systems, gently air-dried to prevent agglomeration from residual heat.

Quality Screening & Packaging

Vibrating screens act as strict quality inspectors, removing oversized, undersized or broken pellets, typically achieving over 95% qualification rate. Perfect pellets are finally bagged, ready to fulfill their mission of nourishing crops and improving soil.

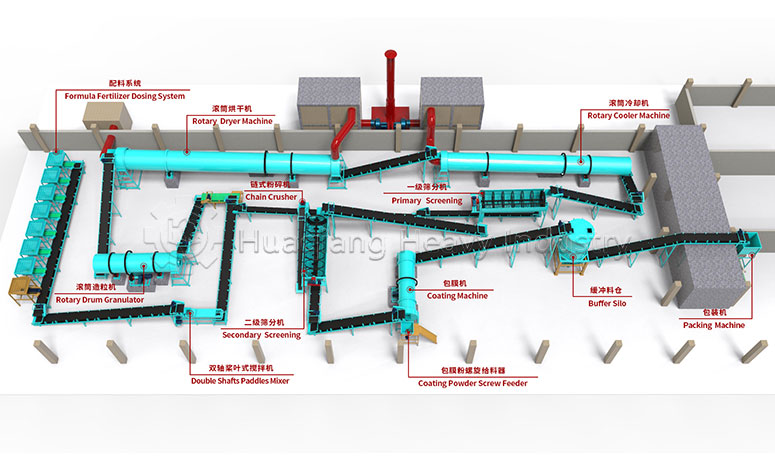

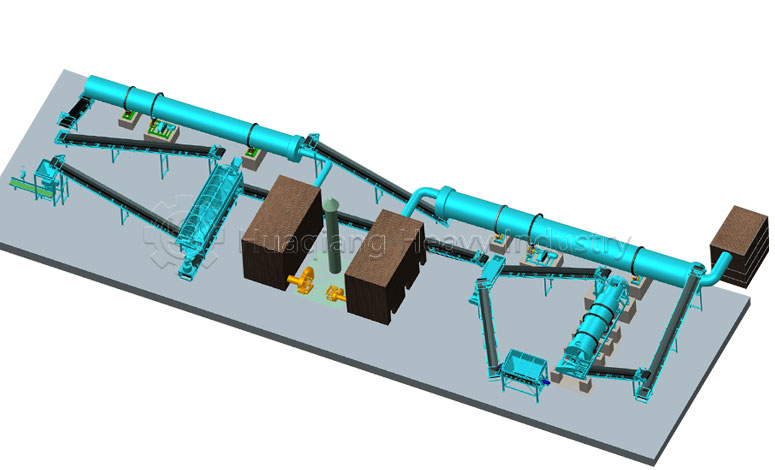

In conclusion, the ring die pelleting machine represents just one sophisticated approach within modern npk fertilizer production technology. This equipment works alongside other crucial machinery like the rotary drum granulator and roller press granulator production line to transform raw materials into premium fertilizers. The complete npk fertilizer production line integrates various processes from initial fertilizer compaction using specialized fertilizer compaction machine equipment to final screening through rotary screener systems. Similarly, organic fertilizer production utilizes equipment such as chain compost turning machine and windrow composting machine for the essential organic fertilizer fermentation process, followed by granulation through innovative new type two in one organic fertilizer granulator. The comprehensive npk manufacturing process and fermentation composting technology for organic fertilizer together form the backbone of modern fertilizer production machine systems. Whether through drum granulation in rotary granulator equipment or fertilizer granules compaction in advanced fertilizer compactor machines, these integrated production lines demonstrate remarkable efficiency in transforming diverse raw materials into uniform, high-quality fertilizers that meet agricultural needs worldwide.

.jpg)