How Long Does Windrow Composting Take?

The duration of windrow composting varies depending on several factors. Under natural conditions, the complete composting process typically requires 1 to 3 months. However, through optimized management practices, this period can be significantly reduced to 2 to 6 weeks. Key factors influencing composting time include pile conditions, turning frequency, and environmental temperature.

When the carbon to nitrogen ratio is maintained within the ideal range of 25:1 to 30:1, and moisture is controlled between 55% and 60%, microbial activity is most active, resulting in the fastest maturation speed. Appropriate turning frequency, such as 1 to 2 times per week, effectively increases pile aeration, promotes oxygen circulation, and accelerates the decomposition process. Ambient temperature is equally crucial, with 20-35°C being the most suitable temperature range. In low-temperature environments, the composting process may extend beyond 3 months.

What are the Disadvantages of Windrow Composting?

Although windrow composting has the advantage of low cost, it also presents some significant limitations. This method heavily depends on natural conditions – rainy weather can easily cause water accumulation in the piles, while sunny conditions may lead to excessive drying. During cold seasons, the composting process nearly stagnates, seriously affecting processing efficiency.

High labor intensity is another major disadvantage, requiring frequent turning operations either manually or mechanically, resulting in lower efficiency for large-scale operations. Simultaneously, uneven ventilation and temperature distribution within the piles often lead to partially uncomposted materials. Additionally, windrow composting requires substantial land area because spaces must be maintained between windrows, resulting in significantly lower processing capacity per unit area compared to other composting methods.

Are Composting Machines Really Effective?

Composting machines do significantly improve composting efficiency and quality. Through forced aeration and mechanical mixing, composting machines can rapidly increase pile temperature to 55-65°C, effectively eliminating pathogens and insect eggs while reducing the maturation cycle by 30% to 50%. This mechanized processing method automatically controls moisture and ventilation, avoiding common problems like water accumulation and oxygen deficiency found in natural composting.

The continuous mixing function of composting machines ensures thorough material blending and uniform maturation degree, making the final product’s fertilizer effect more stable and reliable. In terms of space utilization, the enclosed or semi-enclosed design of composting machines requires only one-third to one-half of the land area per unit processing capacity compared to windrow composting, greatly improving land use efficiency.

Is Windrow Composting Economically Effective?

For small to medium scales and low-cost requirement scenarios, windrow composting is indeed an economically effective choice. The initial investment for this method is relatively low, requiring only simple tools like turners or shovels, without the need for complex equipment investments. The operational technical threshold is low, not requiring professional personnel, making it particularly suitable for farms, orchards, and other venues to independently process organic waste.

From a revenue perspective, the produced organic fertilizer can be used internally or sold, both reducing chemical fertilizer costs and effectively processing waste materials like straw and livestock manure, thereby alleviating environmental pressure. However, during large-scale operations, labor costs and land requirements increase, at which point the economic efficiency may not match that of mechanized composting methods.

Overall, windrow composting provides a practical and sustainable organic waste processing solution for agricultural producers with limited resources. With appropriate scale and management, it can achieve good economic and environmental benefits.

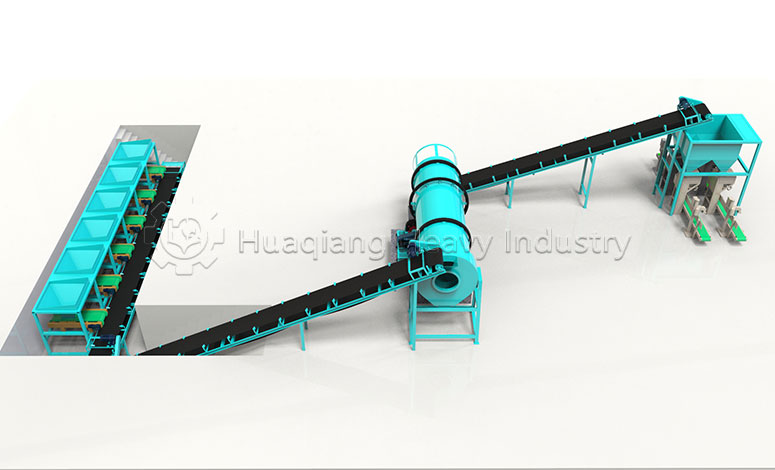

In conclusion, windrow composting remains a viable entry point for organic fertilizer production, particularly when integrated with modern fertilizer production machine systems. The efficiency of the organic fertilizer fermentation process can be significantly boosted by equipment like a large wheel compost turner or chain compost turning machine, accelerating the fermentation composting technology for organic fertilizer. The resulting compost can then be seamlessly processed into high-value products using a complete organic fertilizer production line. This line typically features a rotary drum granulator for drum granulation or a double roller press granulator to form uniform pellets, followed by a drum organic fertilizer dryer. For more complex nutrient profiles, an npk fertilizer production line utilizes a disc granulator in its npk fertilizer manufacturing process. Ultimately, the synergy between efficient windrow machine turning and advanced fertilizer granulator technology within a bio organic fertilizer production line creates a scalable and economical system for transforming waste into valuable soil amendments.