New Type two in one Organic Fertilizer Granulator: The Magician of Organic Fertilizer Production

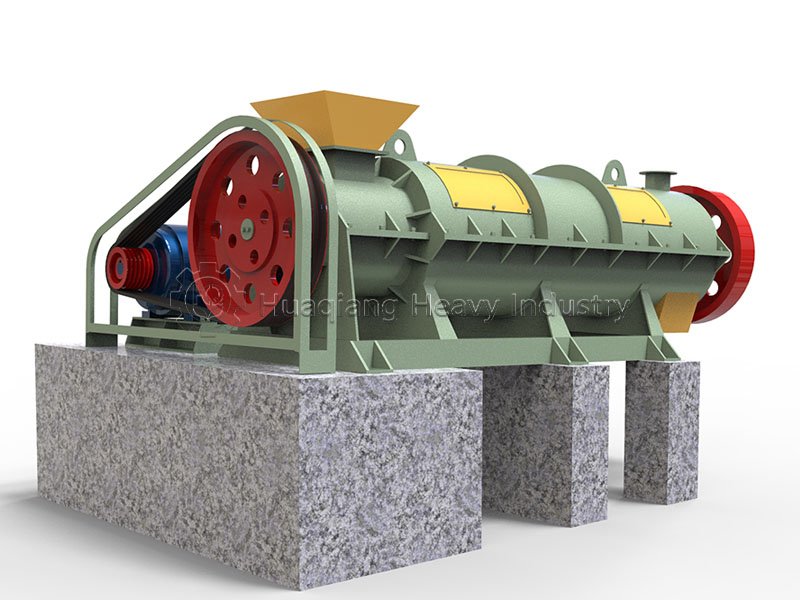

In the organic fertilizer production process, the innovative new type two in one organic fertilizer granulator serves as the core equipment that transforms decomposed organic matter into uniform fertilizer pellets. This advanced machine combines crushing and granulation functions, efficiently processing various organic wastes – including animal manure, agricultural residues, and food waste – into dense, spherical granules with optimal moisture content (typically 25-35%).

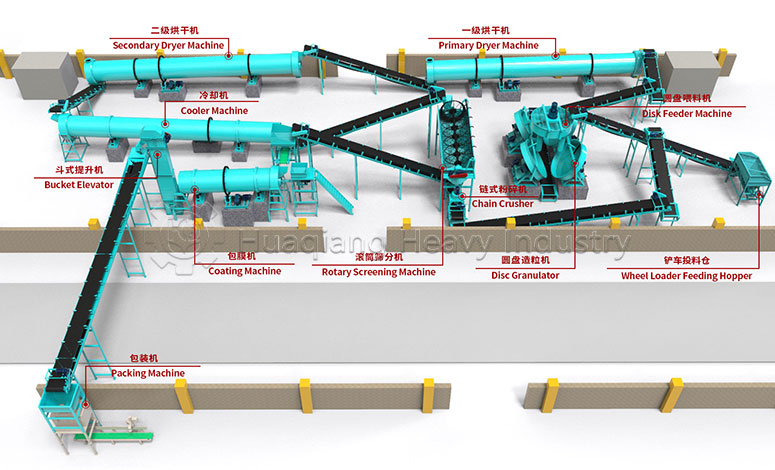

The granulation process begins with pre-treated organic materials entering the rotating drum, where specialized agitators and mechanical forces create the necessary friction and pressure for particle formation. The machine’s dual-action design ensures proper particle size distribution (2-4mm) while maintaining the organic matter’s nutrient integrity. This critical stage bridges the gap between raw material preparation and final product refinement in the complete organic fertilizer production line.

1. The Magical Journey from Waste to Fertilizer

Raw Material Preparation: Fermented organic materials are “chewed” by the crusher into fine 40-60 mesh powder, just like sifting flour before baking a cake. Moisture is precisely controlled within the “golden range” of 25%-35%.

Mixing Magic: In the mixing chamber – this “big bowl”, raw materials and no more than 3% binder dance a 5-10 minute “waltz” until every particle is coated with an even “coat”.

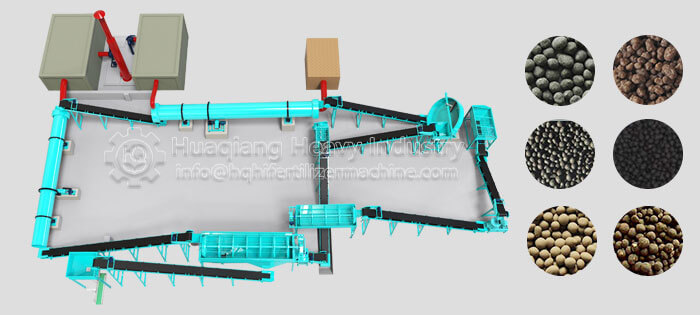

Granulation Transformation: Depending on material characteristics, the equipment performs different “magic” – sticky materials use “tooth stirring magic” for agglomeration, while fibrous materials use “roller pressing magic” for forceful forming, ultimately producing perfect 1-6 mm pellets.

Did you know? Unqualified pellets after screening are sent back to “magic school” for retraining, achieving over 95% material utilization rate, truly realizing “every pellet finds its home”.

2. The Unique Skills of new type two in one organic fertilizer granulator

Space Magician

Eliminating conveyor equipment in traditional production lines, it reduces floor space by 30%-50%, like transforming a two-bedroom apartment into a smart one-bedroom.

Efficiency Master

With hourly output of 1-5 tons and 20%-40% efficiency improvement, it’s like upgrading from a regular train to a high-speed rail.

Granulation Artist

The roundness of the particles reaches over 85%, and the strength reaches 10-30N. It is beautiful and practical, and can be called the “Michelin chef” in the fertilizer industry.

Energy-saving Expert

With 15%-25% lower energy consumption and fewer maintenance points, it’s like a hybrid car that’s both fuel-efficient and low-maintenance.

This new type two in one organic fertilizer granulator is sparking a “granulation revolution” in the global organic fertilizer industry, making production smarter, more efficient, and more environmentally friendly. Next time you see those round, uniform organic fertilizer pellets, remember the magical “magician’s hand” behind them.