In the competitive world of fertilizer manufacturing, operational efficiency and cost-effectiveness are paramount. Success—whether operating a complex npk fertilizer production line or a robust organic fertilizer production line—hinges on selecting the optimal equipment combination. The key question is: how do you maximize output while minimizing capital and operational expenses? Let’s analyze the strategies for building a profitable and efficient operation.

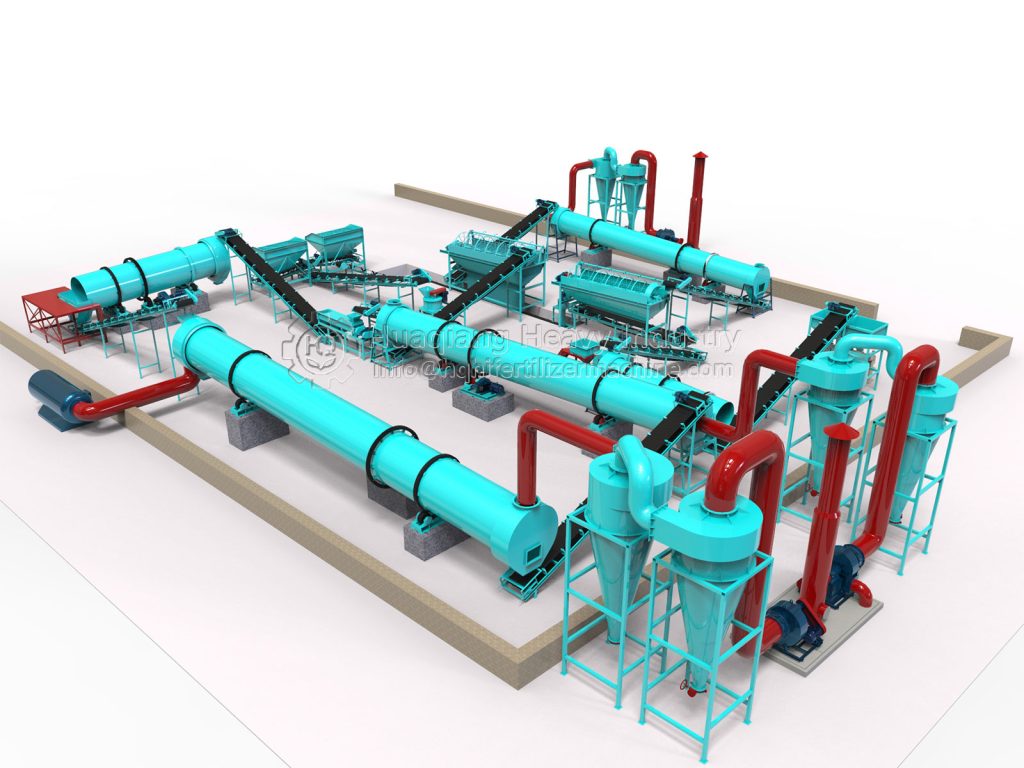

Key Equipment in a Fertilizer Production Line

- Fertilizer Crusher– The backbone of any production line, this machine breaks down raw materials into uniform particles, ensuring smoother processing in later stages.

- Fertilizer Screening Machine– After crushing, this device separates fine particles from oversized chunks, guaranteeing consistent product quality.

- Fertilizer Dryer & Cooler– Moisture control is critical. The dryer removes excess water, while the cooler stabilizes temperature, preventing nutrient loss.

Boosting Efficiency in NPK & Organic Fertilizer Production

To enhance NPK fertilizer manufacturing, a well-synchronized line should include:

– High-speed crushers for uniform raw material breakdown.

– Multi-layer vibrating screens for precise particle separation.

– Rotary dryers with heat recovery to reduce energy waste.

For organic fertilizer production, integrating a compost turner (like the Large Wheel Compost Turner) before crushing ensures faster decomposition, while low-temperature drying preserves microbial activity.

Cutting Costs Without Sacrificing Quality

To reduce organic fertilizer plant costs, consider:

– Combined drying & cooling systems to save space and energy.

– Adjustable screening machines to minimize waste.

– Automated controls to lower labor expenses.

By optimizing equipment selection and workflow, you can achieve higher yields, better quality, and lower operational costs—making your fertilizer business more competitive and sustainable.