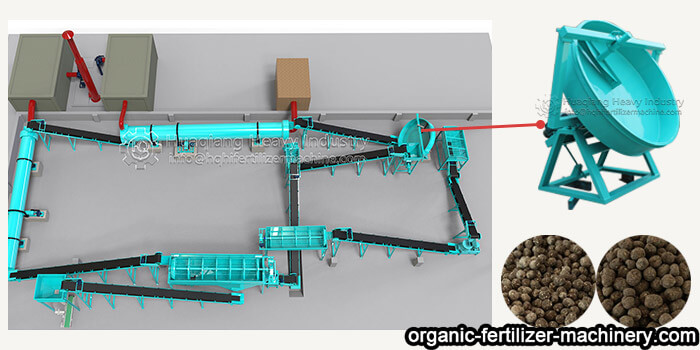

Once the diameter of the disc is determined, the height of the disc can basically be determined. Generally speaking, the larger the diameter, the higher the height of the disc. However, the height of the disc can affect the ball time of the fertilizer on the disc. The particles generated on the disc will be affected by the friction coefficient between the raw material and the disc surface. The difference produces a grading effect. Small particles stay close to the bottom of the disc, while larger particles are discharged beyond the edge. The higher the disc edge, the longer the ball formation time. The disc granulator is an organic fertilizer granulator. If the height of the disc is too low, the pelletizing time will be short, and the particles that come out are relatively small in size. Therefore, on the one hand, the height of the pan can affect the size of the particles discharged from the pelletizing pan, and on the other hand, it can also affect the output. Because if the material stays in the pan for too long, the discharge speed of the product will be slower, the larger the particles of the product, the more particles that do not meet the standard, and the lower the rate of ball formation. Therefore, it is reasonable to choose a high plate height. important.

In the fertilizer production process, since the particles will gradually grow up as they roll down along the surface of the disc, the more the material rolls in the disc per unit time, the faster the particles will grow up, that is, the working efficiency of the granulator It is proportional to the speed of the granulator. Because the basic powder fertilizer rises with the rotation of the disc with a certain slope, it rolls down under the action of gravity, and at the same time, it is thrown to the edge of the disc due to the centrifugal force, these powders collide and fuse with each other, and The liquid phase is bonded together by the surface tension. Therefore, the speed of the speed will affect the bonding and pelletizing process of the powder-grain fertilizer on the one hand. If the rotation speed is too fast, the powder fertilizer will not be formed in time, and it will be thrown out of the disc; too slow rotation speed will cause the powder particles to form a ball for too long, making the diameter of the particles overflowing the disc larger than the standard requirement; on the other hand, with the disc As the inclination angle increases, if the rotation speed of the disc is too slow, the material will accumulate in the lower part of the disc, and the drop and repeated rolling up and down will not occur, which will also affect the ball formation rate. We have some types of organic fertilizer machine.

As the speed of the pelletizing disc increases, the centrifugal force increases, which will make the particles close to the edge of the disc, preventing the particles from rolling down, and a funnel-shaped vortex will appear on the disc surface. In order to maintain the effective use of the disk surface area, the inclination angle of the disk must be increased while increasing the speed. As the inclination angle of the disc increases, the end speed of the particle rolling will increase accordingly, so the inclination angle of the disc should be maintained at a limit value to prevent damage to the rolling and granulation of the material. Therefore, the rotational speed of the disc is also a major influencing factor.

In the organic fertilizer production process, the material pelletized by the disc is generally fermented, and the fermentation tool used at this time is a compost windrow turner.