Fermentation Composting Machines: Driving Sustainable Fertilizer Production

In the pursuit of sustainable agriculture, farm waste management has become a critical task, and agricultural waste composting and fermentation machines have emerged as game-changers. These innovative devices efficiently transform agricultural by-products such as manure and crop residues into nutrient-rich compost, revolutionizing how farmers handle waste while promoting environmentally friendly fertilizer production. By precisely controlling temperature, humidity, and oxygen levels, they shorten the decomposition cycle from months to weeks, addressing environmental concerns, reducing labor costs, and offering scalable solutions suitable for both small farms and large-scale industrial operations.

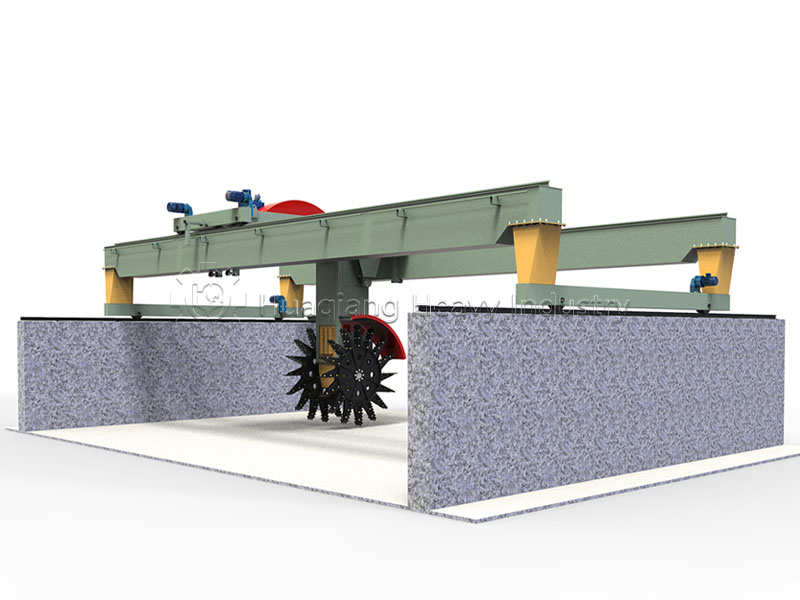

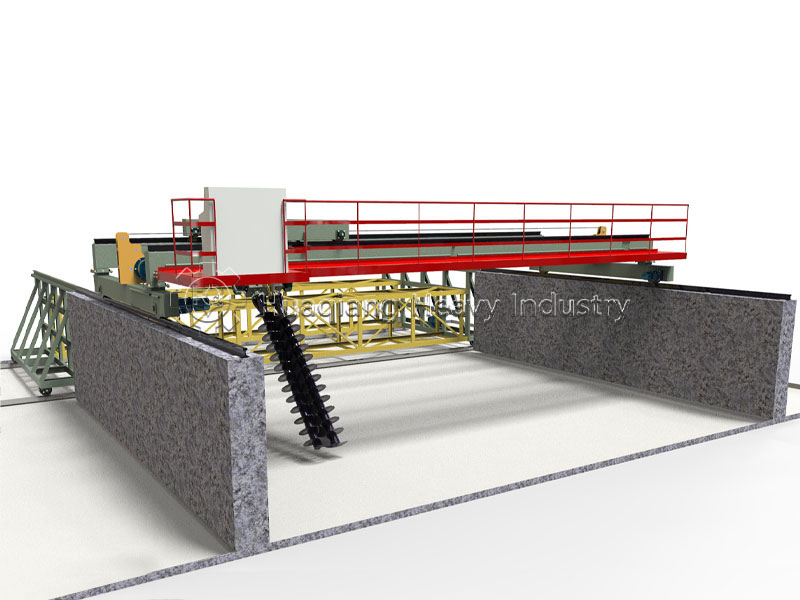

Various types of machines and technologies cater to different agricultural needs, each with its unique advantages. Vertical or enclosed fermentation tanks utilize enclosed vessels with forced ventilation and heat recovery systems to create optimal fermentation conditions. This enclosed design prevents contamination, retains heat, and accelerates the fermentation process to just 7-15 days, making it ideal for operations focused on efficiency and environmental compliance. Windrow and forklift-type compost turning machines are designed for large-scale production; they mechanically turn long rows of organic material, ensuring even aeration and mixing, laying the foundation for thorough decomposition.

Fermentation film winding machines offer a practical solution for open-air compost piles, especially in colder climates. By covering the compost piles with a layer of nanofilm, they retain heat, preserve moisture, and suppress odors, effectively accelerating fermentation even in low temperatures. Together, these technologies form a comprehensive toolkit for transforming agricultural waste into valuable resources.

The key features of these machines deliver tangible benefits to farmers and the environment. Speed is a prominent advantage—reducing composting time from months to 7-15 days significantly increases production efficiency. Enclosed systems and specialized films minimize odors and pests, helping to meet stringent environmental standards. During the fermentation process, temperatures in the thermophilic phase reach 60-80°C, killing pathogens and producing high-quality, nutrient-rich organic fertilizer, thereby improving soil health. Automated operation and corrosion-resistant stainless steel construction reduce labor requirements and extend machine lifespan, while its versatility allows it to handle a variety of waste materials, including manure, sludge, straw, and food waste. This flexibility makes it indispensable in diverse agricultural and waste management scenarios.

The general workflow of these machines follows a simplified sequence. Waste is first automatically loaded into the equipment, then an aeration system (sometimes using heated air) and mixing blades ensure sufficient oxygen is provided to the aerobic microorganisms, which are the key drivers of the decomposition process. Microbial activity generates heat, initiating a high-temperature phase that kills pathogens. After the initial rapid fermentation, a secondary cooling and maturation phase completes the decomposition of organic matter. Finally, the finished compost is discharged, ready for direct use or packaging.

Agricultural waste composting and fermentation equipment bridges the gap between waste management and sustainable agriculture. They transform potential pollutants into valuable fertilizers, reducing environmental impact and increasing agricultural efficiency, paving the way for a greener and more productive agricultural future.

From Composting to Commercial Fertilizer Product

The matured compost produced by these machines is the foundational raw material for a complete organic fertilizer fermentation process. To commercialize this compost, it must be integrated into a broader production system. The cured material from a windrow composting machine, a large wheel compost turning machine, or a more advanced trough-type aerobic fermentation composting technology system (collectively representing advanced fermentation composting turning technology) becomes the feedstock for value addition.

This compost then feeds into the comprehensive suite of equipments required for biofertilizer production. For shaping the material into a marketable form, a disc granulation production line is commonly used to create spherical granules. Alternatively, a flat die press pellet machine for sale can produce dense cylindrical pellets via extrusion. The entire system, from initial decomposition in an agriculture waste compost fermentation machine or a self propelled compost production machine to final granulation, exemplifies modern fermentation composting technology for organic fertilizer, closing the loop from waste to valuable agricultural input.

This integrated approach ensures that farm waste is not merely processed but systematically upgraded into a standardized, easy-to-handle fertilizer product, maximizing resource recovery and supporting a circular economy in agriculture.