Recently, Zhengzhou Huaqiang Heavy Industry Technology Co., Ltd.’s customized 4.0-type extrusion granulation production line for its Pakistani client completed full-process installation and commissioning, officially entering the stage of large-scale production. This production line focuses on the high-efficiency granulation needs of compound fertilizers and organic fertilizers. Centered on a 4.0-type double-roller extrusion granulator, it integrates the entire chain of processes including feeding, conveying, screening, storage, and packaging. Coupled with a custom-designed steel structure plant layout, its stable operating performance, precise granulation effect, and adaptability to local production conditions have made it a benchmark project for China’s high-end granulation equipment to empower South Asian agriculture.

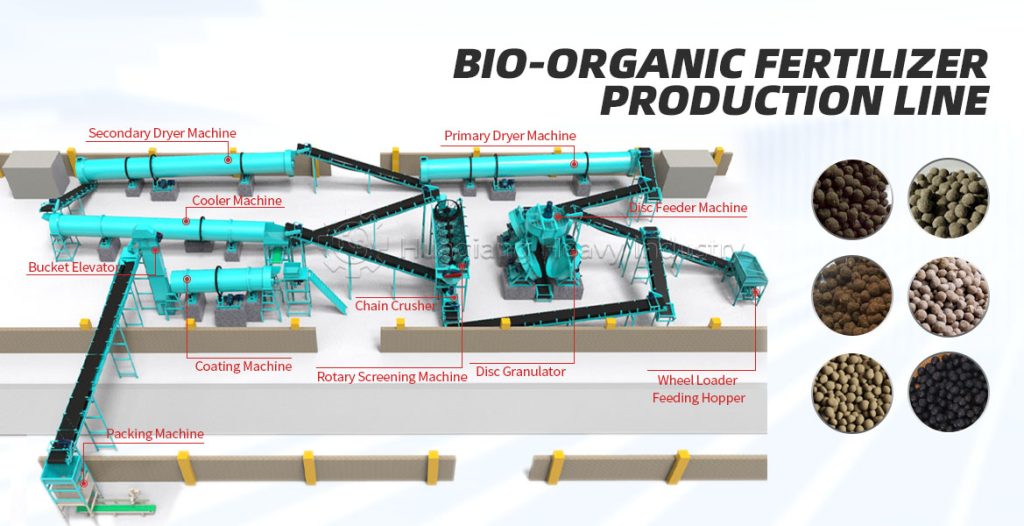

Production Line Full-Process Configuration and Core Equipment Analysis

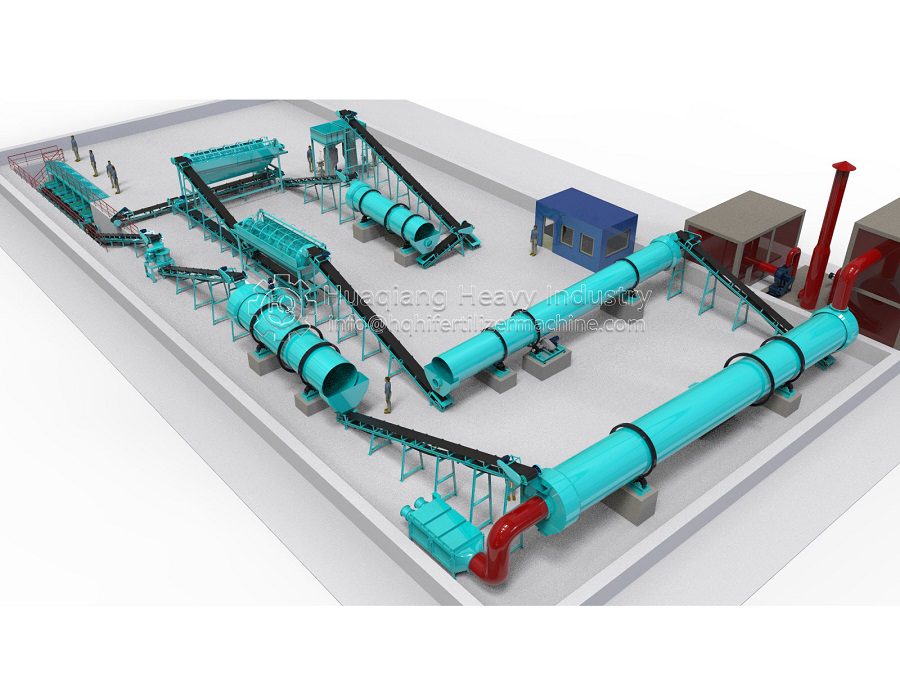

The entire production line follows a closed-loop process of “raw material pretreatment – precise granulation – grading and screening – finished product output.” The equipment selection is professional, the layout is compact and orderly, and the connections between each unit are seamless, ensuring both production efficiency and strict product quality control, fully adapting to the raw material characteristics and production capacity requirements of Pakistan.

Raw Material Conveying and Feeding Unit: Stable Supply Lays a Solid Foundation

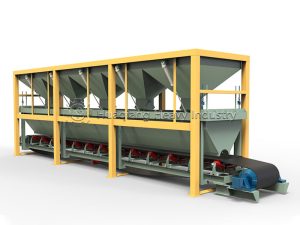

Raw Material Feeding and Lifting: The production line starts with a loader-loaded hopper. The hopper features a large-capacity, open design to accommodate the rapid loading of bulk raw materials. The feed inlet is equipped with a spill-proof buffer device to reduce material loss and dust. Raw materials are vertically conveyed to subsequent stages via a 315-type bucket elevator (10 meters). This elevator uses a plate chain drive structure, boasting strong load-bearing capacity, stable operation, and a conveying efficiency of 8 tons/hour. Its excellent sealing effectively prevents materials from becoming damp or contaminated during lifting, ensuring the purity of the raw materials.

Precise Feed Control: The enhanced raw materials are conveyed to the granulation unit via a 16-type screw feeder. This feeder employs variable frequency speed control technology, allowing real-time adjustment of the feed rate based on the granulator’s operating status (adjustment range 0.5-2 tons/hour). Combined with a material level monitoring sensor, precise control of the feed rate is achieved, preventing granulation quality fluctuations or equipment overload caused by uneven feeding, thus ensuring stable granulation.

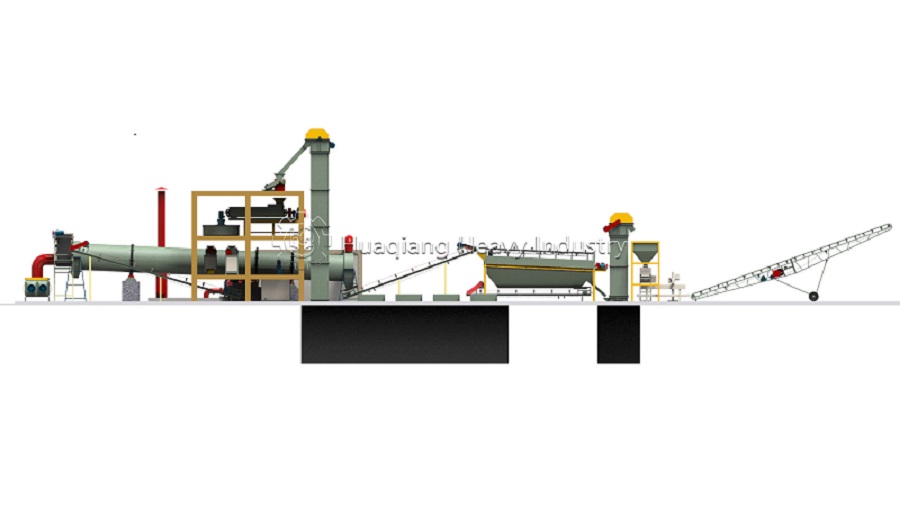

Core Granulation Unit: 4.0-Type Main Unit forges high-quality granules

The core equipment of the production line is the 4.0-type double-roller extrusion granulator. This high-end model, developed by Huaqiang Heavy Industry for medium to large-scale fertilizer production enterprises, features a high-strength alloy double-roller design with a roll diameter of 400mm and a roll width of 300mm. The extrusion pressure (8-20MPa) is precisely controlled through a hydraulic pressurization system, adapting to the granulation needs of raw materials with different moisture content (25%-35%) and different compositions.

The granulator rollers are made of high-chromium wear-resistant alloy, achieving a hardness of HRC65 or higher after quenching. This provides four times the wear resistance of ordinary materials and extends the service life to over 12,000 hours. The roller surface features a customized anti-slip texture design, enhancing material gripping force and maintaining a stable granulation rate of over 95%. Particle size is uniformly controlled at 3-6mm, with a compressive strength of 3.0MPa, preventing pulverization and fully meeting the needs of long-distance transportation and field application in Pakistan. The equipment is equipped with an automatic roller cleaning device that removes adhering material from the roller surface in real time, preventing die blockage and ensuring continuous operating efficiency.

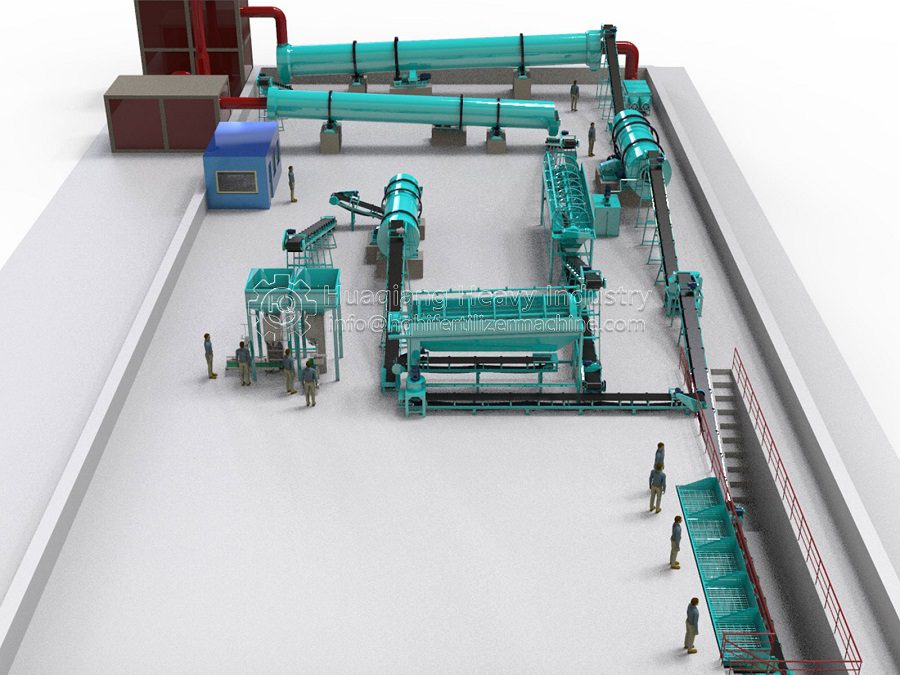

Grading and Recycled Material Unit: Strict Quality Control and Improved Utilization Rate

The granulated particles are transferred via a 5-meter belt conveyor to a 1.2×4.0-meter drum screen. This equipment uses a single-layer high-precision screen design, with screen apertures customizable to customer requirements. Grading and screening are achieved through uniform drum rotation (20 r/min). Qualified particles (3-6 mm in diameter) achieve a 98% pass rate. Substandard particles (too coarse or too fine) are returned to the raw material conveyor via 4-meter and 5-meter recycled material belt conveyors, re-entering the granulation process. Material utilization reaches 99%, effectively reducing production costs.

The screen is equipped with a vibration cleaning device to clean material adhering to the screen surface in real time, preventing screen blockage and ensuring stable screening efficiency. The equipment adopts a sealed enclosure design to reduce dust pollution generated during screening, meeting local environmental protection requirements.

Finished Product Storage and Packaging Unit: High-Efficiency Output Ensures Quality

Qualified granules are conveyed to the finished product silo via a 315-type bucket elevator (6 meters). The silo features a sealed design and is equipped with a dehumidification and ventilation system to effectively prevent fertilizer from absorbing moisture and clumping, ensuring product storage stability. The silo capacity can meet the finished product storage needs of continuous 4 hours of full-load production. Material level sensors are installed inside the silo to provide real-time feedback on inventory status, facilitating customers’ rational planning of shipments.

The packaging process is equipped with an automatic packaging scale, supporting rapid switching between various packaging specifications such as 25kg and 50kg. It uses a gravity-based metering principle, coupled with a high-precision sensor, with a metering error ≤ ±0.1kg and a packaging speed of up to 100 bags/hour. The packaged finished products are flexibly transferred to the finished product stacking area via a 12-meter mobile conveyor belt. The mobile conveyor belt can be adjusted in direction and angle according to site requirements, adapting to the spatial layout of the steel structure factory and improving shipment flexibility.

Core Advantages and Adaptability of the Production Line

Dedicated Steel Structure Adaptation Design: The production line layout fully integrates with the load-bearing and spatial characteristics of steel structure workshops. Equipment spacing and installation height are precisely matched, requiring only 500 square meters of floor space, saving 20%of space compared to traditional production lines. It also optimizes equipment maintenance access, facilitating later maintenance operations.

Stable, Reliable, and Highly Adaptable: Core equipment adopts high-temperature, wear-resistant, and corrosion-resistant designs, adapting to the hot and dry climate conditions of Pakistan. The 4.0-type granulator can flexibly adapt to various materials such as organic fertilizer, compound fertilizer, and bio-organic fertilizer, supporting rapid switching between different formulations to meet the diverse agricultural fertilization needs of the region.

Intelligent, Convenient, and Easy to Operate: The entire production line integrates a simple control system with a bilingual (Chinese and English) operating interface. Key parameters (pressure, speed, feed rate) are displayed in real time, supporting manual and automatic mode switching, allowing local operators to quickly learn how to use it. Key components adopt standardized designs, and vulnerable parts are highly interchangeable. The company provides comprehensive spare parts supply and technical guidance services, reducing later maintenance costs. The successful commissioning of the 4.0 extrusion pelletizing production line in Pakistan not only demonstrates Huaqiang Heavy Industry’s core strength in the R&D of high-end pelletizing equipment and the implementation of overseas projects, but also provides efficient and stable equipment support for the modernization of agriculture in South Asia. In the future, Huaqiang Heavy Industry will continue to focus on the production needs of different regions, optimize product performance and process solutions, and provide more competitive customized solutions for global customers, enabling “Made in China” to benefit the agricultural industries of more countries and regions.

Core Technology: Roller Press Compaction and Broader Process Integration

This successful project in Pakistan exemplifies the efficiency of extrusion-based granulation. The central double roller press granulator operates on the principle of fertilizer granules compaction, where dry or low-moisture powder is compressed between two counter-rotating rollers under high pressure to form dense, uniform granules. This method is a cornerstone of modern roller press granulator production line setups. The fertilizer compactor (another term for the press) is particularly advantageous in the npk fertilizer manufacturing process as it avoids the need for drying, reducing energy consumption and preserving heat-sensitive nutrients.

The robust fertilizer compaction machine showcased here is not limited to complex formulations. Its technology is highly adaptable and can be seamlessly integrated into a broader npk manufacturing process. While ideal for blended NPK powders, the same granulation principle effectively processes a wide range of materials, including single-nutrient fertilizers, organic-based mixes, and soil amendments, demonstrating remarkable versatility within a complete fertilizer production ecosystem.

This underscores the strategic value of selecting a core granulation technology that offers both high mechanical strength in the final product and operational flexibility, allowing production lines to pivot between different fertilizer types to meet dynamic market demands.