How chicken manure is turned into fertilizer and the equipment used

The large amount of chicken manure produced by chicken farms every day was once a headache for farmers – it piled up and occupied land, the odor disturbed people, and polluted the environment. Today, with the upgrading of environmental protection technology, chicken manure has transformed into high-quality organic fertilizer, and this “gorgeous transformation” is inseparable from the help of professional processing equipment.

The core of chicken manure turning into fertilizer is composting and fermentation. Fresh chicken manure contains a lot of pathogens, insect eggs, and a strong smell of ammonia nitrogen. Direct use will burn the roots of crops and attract pests and diseases. Therefore, the first step is to “disinfect and improve the quality” of chicken manure.

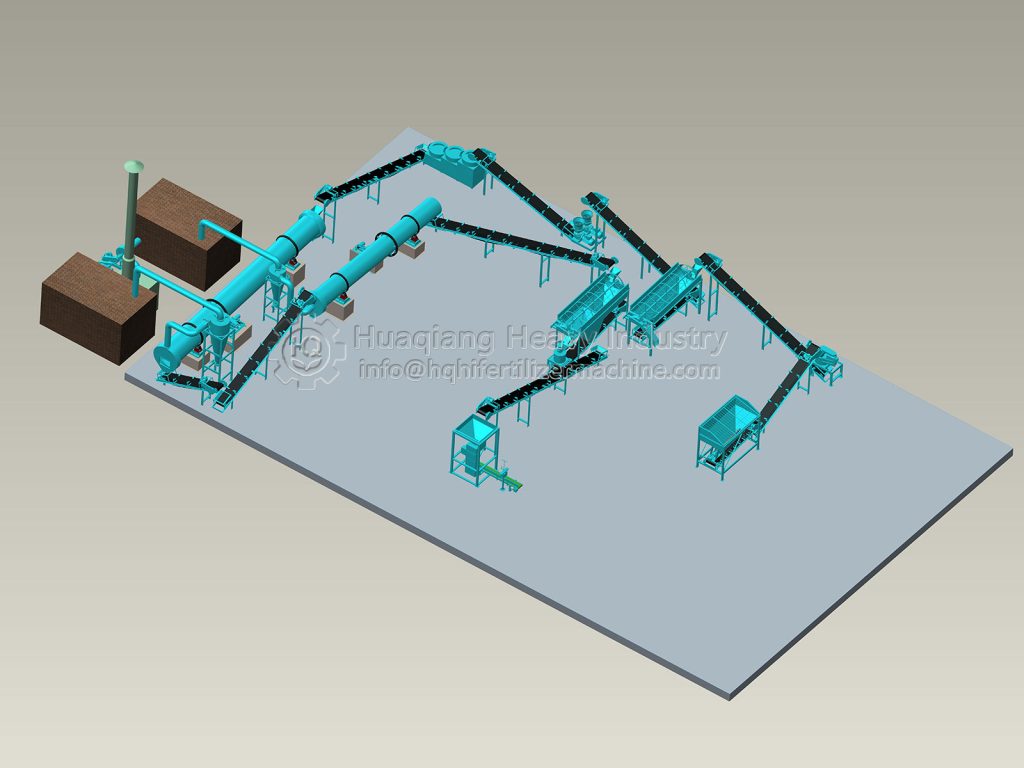

First, send the chicken manure to the dewatering machine to remove excess water. The dehydrated chicken manure cannot be fermented directly, but must be matched with straw and sawdust to adjust the air permeability and make the fermentation more complete.

The mixed materials are sent to the fermentation area, and the turning machine (such as the compost turning machine) is on the scene to turn the materials regularly to ensure sufficient air, so that the upper and lower layers are heated evenly to ensure the fermentation effect.

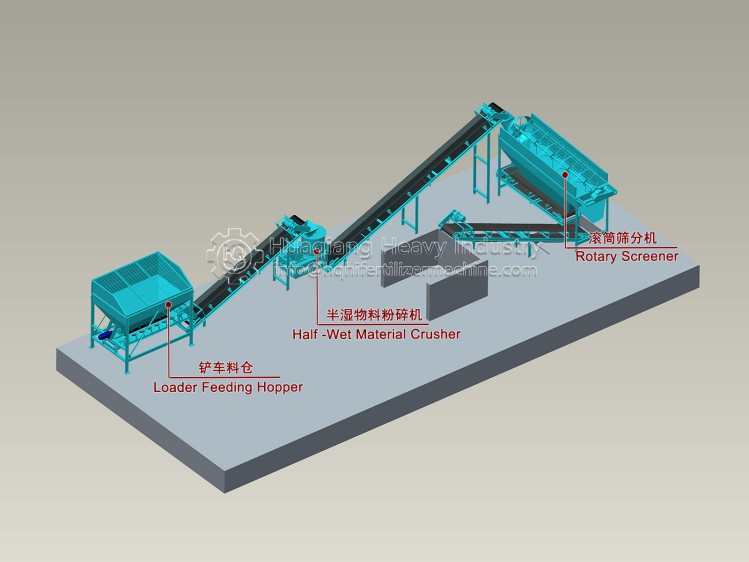

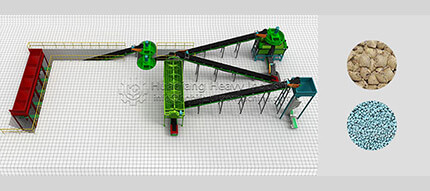

The fermented materials are crushed and agglomerated by a pulverizer, and the impurities are removed by a drum screener machine. The powdered organic fertilizer obtained can be used directly. If you want to improve storage stability and application convenience, you can perform granulation.

Granulation requires an organic fertilizer granulator to condense the powdered material into uniform particles. Granular fertilizer is not easy to absorb moisture and agglomerate, and it is resistant to loss during transportation and storage. When applied, the amount can be controlled to prevent waste. It can also slowly release fertilizer in the soil, prolong fertilizer effect, and improve crop absorption efficiency.

This system not only solves environmental problems, but also creates profits. Chicken manure organic fertilizer improves soil, improves the quality of fruits and vegetables, and is very popular.

From waste to “hot cakes”, the counterattack of chicken manure is clear. Choose professional equipment to turn chicken manure into treasure, protect green waters and green mountains, and collect gold and silver mountains. This is a wise choice for the circular development of modern agriculture.