BB Fertilizer Production Line: Characteristics and Advantages

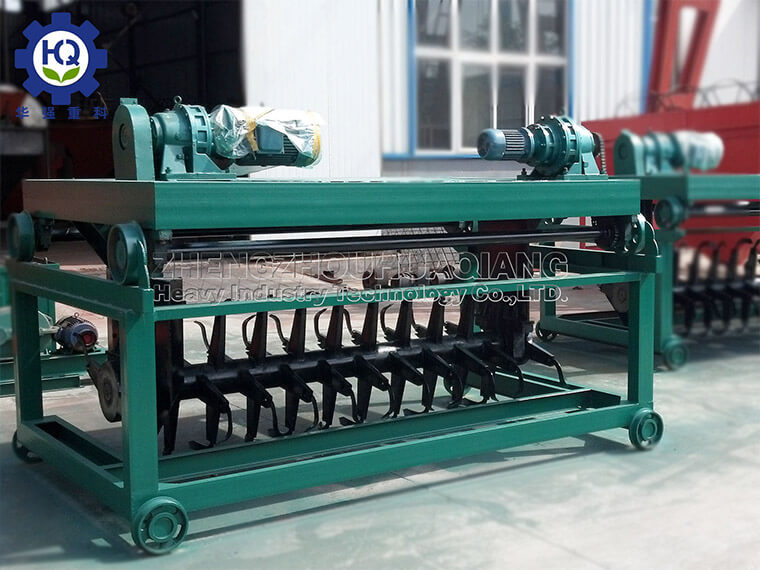

The BB fertilizer production line is a complete set of BB fertilizer production equipment designed for BB fertilizer production. A complete BB fertilizer production line includes an automatic batching system, a fertilizer conveyor, a fertilizer mixer, a finished product storage bin, a fertilizer packaging machine, etc. In the process of fertilizer production, BB fertilizer production lines have many characteristics, such as:

Ease of Material Handling: The material is transported to the ground, making transportation convenient and fast. There is no need for a lifting mechanism, requiring fewer laborers for material feeding, and it ensures safe operation.

High Yield: It has a large output capacity and offers multiple specifications, effectively addressing the seasonal concentrated demand for BB fertilizer.

Compact Footprint: The batching system is positioned below, making the production line compact with a small footprint and low height.

Fully Automated: Controlled by computers, the entire production process is automated, which enhances efficiency and reduces labor intensity.

High Accuracy: Both batching and packaging use electronic weighing, ensuring strict control over the ratios.

Good Process: It does not damage the original particle shape of the materials and prevents re-segregation of mixed finished products; the batch-wise intermittent mixing method ensures high uniformity.

Easy Cleaning: There are no dead corners for raw materials in the production line, allowing for easy and simple cleaning after shutdown.

Strong Adaptability: Suitable for various harsh field environments, including cold northern regions and humid southern areas.

Environmental Protection and Energy Efficiency: Some advanced models adopt energy-saving designs, reducing energy consumption and environmental pollution.

With the increasing awareness of environmental protection and energy saving among the public, as well as the growing pursuit of green organic food in recent years, the production and application of BB fertilizer have become more widespread. With the advancement of future technology, BB fertilizer production lines will become increasingly perfect, bringing more support to fertilizer production and agricultural development.