How long does it take to build an organic fertilizer production line

The construction time of an organic fertilizer production line will be affected by multiple factors, including the scale of the production line, the complexity of the equipment, the response speed of the supplier, the scale of the civil engineering project, the installation and commissioning time, and the local administrative approval process. Here is a rough timeline, but please note that actual times may vary:.jpg)

Project planning and design (1-3 months): including market research, organic fertilizer production line design, equipment selection, cost estimation, project planning, etc. At this stage, it may be necessary to communicate with multiple suppliers for technical exchange and scheme comparison.

Administrative approval (1-3 months): including project initiation, environmental impact assessment, land use approval, construction planning permit, etc. The duration of this stage will vary depending on the approval speed of local government departments and the specific situation of the project.

Civil construction (3-6 months): including land leveling, infrastructure construction, factory building, equipment foundation construction, etc. The construction time will vary depending on the scale and complexity of the project.

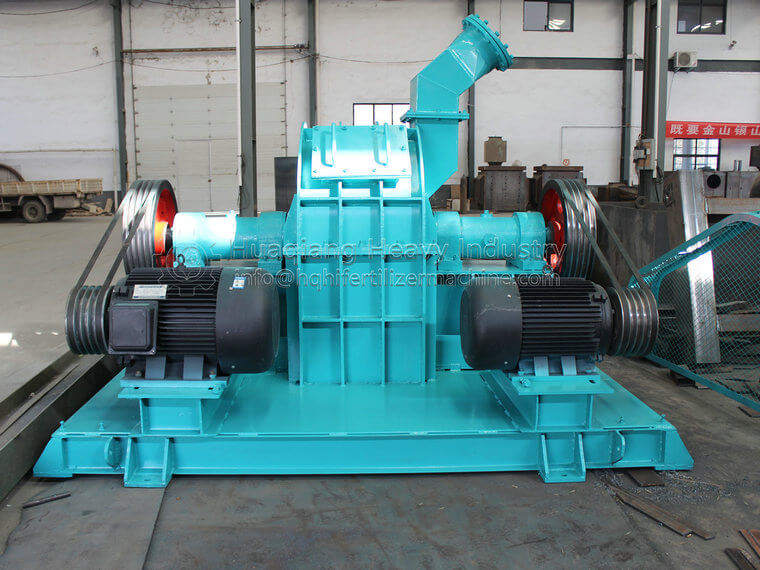

Equipment procurement and manufacturing (2-6 months): including equipment customization, production, testing, packaging, etc. If the equipment needs to be imported from abroad, the time may be longer.

Equipment installation and commissioning (1-2 months): including equipment transportation, installation, pipeline connection, electrical wiring, control system setup, trial operation, etc.

Employee training and trial production (1-2 months): including training for operators, trial operation of production lines, testing and adjustment of product quality, preparation work before formal production, etc.

In summary, from project planning to formal production, the construction of a medium-sized organic fertilizer production line may take 1 to 1.5 years. For small production lines, the time may be shorter; For large production lines, the time may be longer. In practical operation, project management, supply chain management, risk management, etc. are all important factors that affect project progress. In order to ensure the smooth progress of the project, it is recommended to develop a detailed project plan at the beginning of the project, including timetable, budget, resource allocation, risk management, etc., and conduct strict project management during the project execution process to cope with possible challenges and delays.

.jpg)

.jpg)

.jpg)