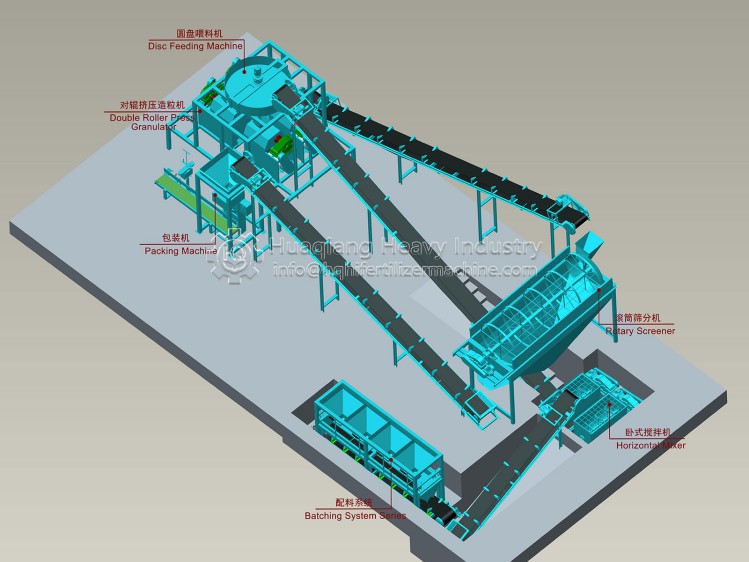

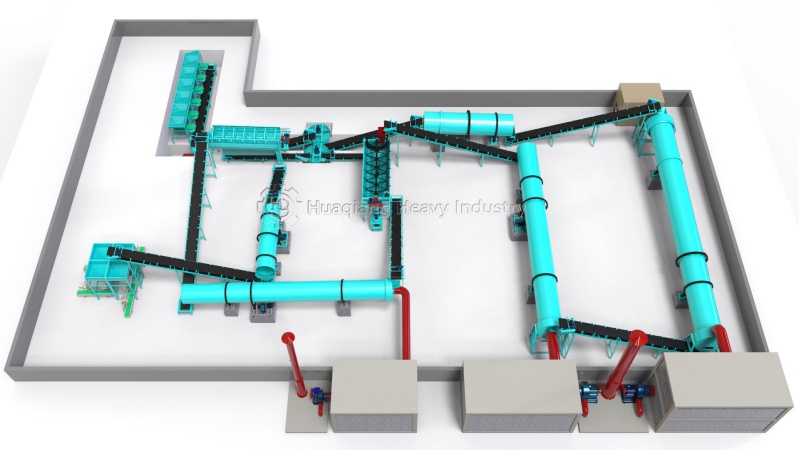

Equipment and process required for potassium persulfate fertilizer production line

The granulation processing equipment required for the production line of potassium persulfate fertilizer mainly includes granulators, crushers, mixers, etc. The process flow of the fertilizer production line is as follows:

Ingredients: Check the name, quantity, manufacturer, production batch number, and qualified status of the raw materials, and then unpack and transfer them to the weighing room. Two people will double check the weighed materials and crush them according to the crushing operation procedures. After the crushing is completed, sieve them according to the sieving operation procedures. Double check and weigh the sieved prescription amount of materials, mix them according to the preparation operating procedures, and transfer the materials to the next position after preparation.

Granulation: Two people review the materials and use a fertilizer granulator to granulate according to the granulation operation procedures. After the granulation is completed, the particles are placed on a tray and evenly spread. The operator of the drying position pushes the tray into the oven, opens the oven, and when the temperature rises to the specified range, counts the time to dry according to the specified time.

The job operators use a fertilizer dryer to aggregate the dried particles in accordance with the granulation operation procedures, and after completion, transfer the qualified particles to the next process. The job operators mix the whole particles according to the overall mixing operation procedures and transfer them to the next position after completion.

Please note that this is just a simple granulation process. The actual process flow may vary depending on different products and specific production conditions,

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)