How much does it cost to build an organic fertilizer production line in a breeding farm

Organic fertilizer processing materials are widely used, including poultry and livestock manure, earthworm manure, fungal spore residue, and distiller’s grains sludge, all of which can be used as processing materials for organic fertilizer at a low purchase price and not much cost. People who are new to the organic fertilizer industry and want to invest in organic fertilizer factories for processing have doubts. Processing and producing organic fertilizer requires essential equipment for the organic fertilizer production line. What equipment should be purchased? How much does the total cost of organic fertilizer production equipment cost?

Annual output of organic fertilizer production equipment:

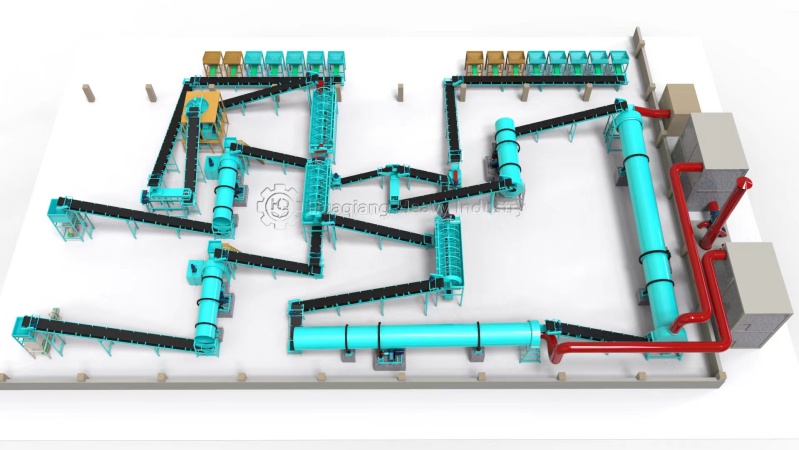

Equipment configuration, price, and plan for supporting organic fertilizer production in small and medium-sized livestock and poultry manure farms with a daily volume of 5-10 cubic meters: small-scale annual output of 20-10000 tons, medium-sized production of 1-50000 tons, and large-scale production of over 50000 tons. The price of small organic fertilizer production equipment is below 300000 yuan, medium equipment costs 300000 to 500000 yuan, and large equipment costs over 500000 yuan.

Suggestions for facility investment required for different scales of organic fertilizer production

Generally, small and medium-sized farms produce their own supporting facilities, with a daily output of less than 5 cubic meters of animal and poultry manure. The investment in the production scale of organic fertilizer for small-scale organic fertilizer production is recommended as follows:

1. No professional equipment is required, just stack and ferment in the manure shed in a staggered manner every day, and then use or sell it for personal use.

If the daily production of animal manure exceeds 5 cubic meters and the maximum does not exceed 10 cubic meters in a breeding farm, simple facilities can be purchased, mainly small forklifts, mobile composting machines, crushers, and other facilities, with an investment cost of 100000 to 300000 yuan.

3. If the daily production of livestock and poultry manure exceeds 10 cubic meters, it is recommended to provide more equipment, which generally requires an investment of 300000 to 600000 yuan. A complete and complete equipment may require over one million yuan.

4. For medium to large organic fertilizer plants, it is necessary to develop several organic fertilizer production lines based on specific products, and add equipment according to Article 3.

.jpg)