On the vast stage of industrial production, the rotary dryer performs like a skilled dancer, using its unique drying techniques to bring about perfect “transformations” for various materials. What wisdom and charm does this seemingly simple equipment possess? Let’s uncover its mysteries together.

The Elegant Dance of Drying

When moist materials gently enter the drum through the feed inlet, an exquisite drying journey begins. Driven by the transmission device, the drum rotates at an elegant pace, as if performing a carefully choreographed dance. The lifters inside the drum act like graceful dance partners, gently lifting and cascading the materials, creating a continuous curtain of falling particles.

High-temperature hot air meets the materials on this rotating stage, where water molecules quietly evaporate in this warm embrace. This intimate contact drying method not only achieves remarkable efficiency but also ensures uniform heating, preventing localized overheating or insufficient drying.

As the drum continues to rotate, the materials undergo graceful transformations through continuous lifting and falling. Each elevation and descent increases the contact area between materials and hot air, maximizing drying effectiveness. Finally, the dried materials make their elegant exit through the discharge port, while the spent hot air departs orderly through the specialized exhaust treatment system.

Multifaceted Excellence in Performance

High-Efficiency Drying Star

Utilizing direct contact drying design with exceptionally high thermal efficiency. The rapid drying speed and powerful processing capacity multiply production efficiency, making it a valuable asset on production lines.

Versatile Adaptation Expert

Whether dealing with fine powders or coarse granules, regular shapes or unique forms, this equipment handles everything with ease, demonstrating remarkable adaptability.

Simple Yet Sophisticated

Clean structural design enables easy maintenance and operation. Even novice operators can quickly master its operation, significantly reducing training costs and time.

Flexible Energy Options

Offers multiple heat source choices including coal, oil, and gas, allowing flexible configuration based on local energy availability to ensure stable operation in any environment.

Precise Process Control

By adjusting parameters such as drum rotation speed and hot air temperature, drying levels can be precisely controlled to meet the specific requirements of different materials.

Wisdom and Challenges Coexisting

Of course, any excellent equipment faces its own challenges. When processing large quantities of materials, the rotary dryer’s energy consumption is relatively high, reminding us to consider rational energy use while pursuing efficiency. Modern technology continues to optimize this aspect through innovative solutions like heat recovery systems and intelligent controls.

From chemical raw materials to food processing, from mineral development to agricultural production, the rotary dryer plays an irreplaceable role across various sectors with its reliable performance and flexible applications. It’s not just a machine, but a trusted partner in industrial production.

In this era that values both efficiency and quality, the rotary dryer continues to perform brilliant chapters on the industrial drying stage with its unique charm, injecting continuous momentum into the development of various industries.

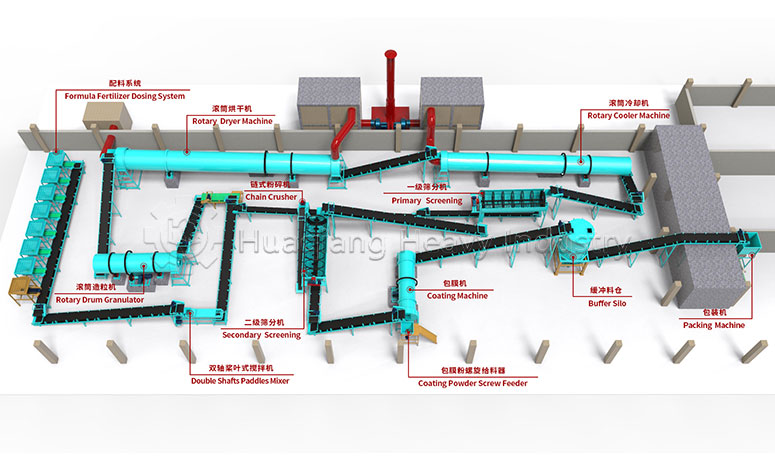

In conclusion, the rotary dryer serves as an indispensable component within comprehensive fertilizer manufacturing systems, providing crucial moisture control capabilities that complement various fertilizer granulation processes. This equipment integrates seamlessly into both organic fertilizer production line and npk fertilizer production line configurations, working in harmony with other essential machinery. In bio organic fertilizer production line setups, dryers process materials after windrow composting machine treatment and subsequent granulation through equipment like disc granulator machine. Similarly, in the complete npk fertilizer line, drying represents a vital step following blending by npk blending machine and forming through fertilizer granulator systems such as double roller press granulator or disc granulation production line. The synergy between drying technology and granulation equipment ensures final products meet quality standards for moisture content, hardness, and storage stability. As fertilizer production evolves, the integration of efficient drying systems continues to enhance overall production efficiency and product quality across all fertilizer types.