Roller press granulation technology: A reliable choice for improving the strength and uniformity of fertilizer granules

The strength and uniformity of fertilizer granules directly affect their transportation and storage stability and application effectiveness, making them a core indicator of high-quality fertilizers. Roller press granulation technology, with its unique principle of “dry extrusion and die-hole molding,” can precisely control particle characteristics from the molding source, effectively improving strength uniformity.

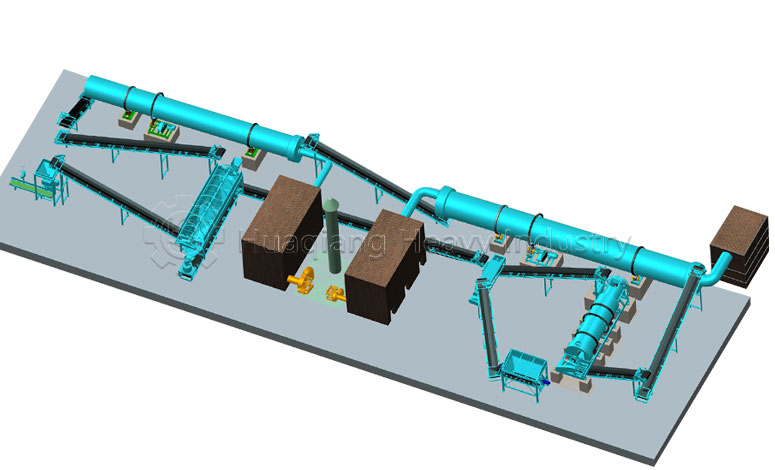

Roller press granulation uses the synchronized pressure rollers of a fertilizer compaction machine to apply constant pressure to dry powder raw materials that have been mixed by a fertilizer mixer and screened by a fertilizer screener machine. The raw materials are then extruded and molded through die holes. The fertilizer compaction machine’s pressure control is precise, and the roller speed and pressure are constant, ensuring that each granule receives the same extrusion pressure, thus preventing strength differences caused by uneven pressure from the source.

This technology has wide raw material adaptability; NPK compound fertilizers and other materials, after pretreatment, can be stably granulated through the fertilizer compaction machine. At the same time, the precise feeding system of the fertilizer compaction machine can stabilize the raw material supply speed, avoiding local pressure changes caused by feeding fluctuations; secondary screening after molding removes irregular particles, further improving the consistency of finished product particle size and strength.

In practical applications, fertilizer granules produced by roller press granulation have a coefficient of variation in strength of ≤5%, far superior to traditional processes, with a transportation pulverization rate of less than 2%. This meets the high requirements for particle stability in large-scale planting, reducing fertilizer waste and ensuring uniform application. In summary, roller press granulation technology, through precise pressure control and process optimization, can significantly improve the strength and uniformity of fertilizer granules, providing strong support for the production of high-quality fertilizers.