How to improve the operating efficiency of trough-type compost turning machines?

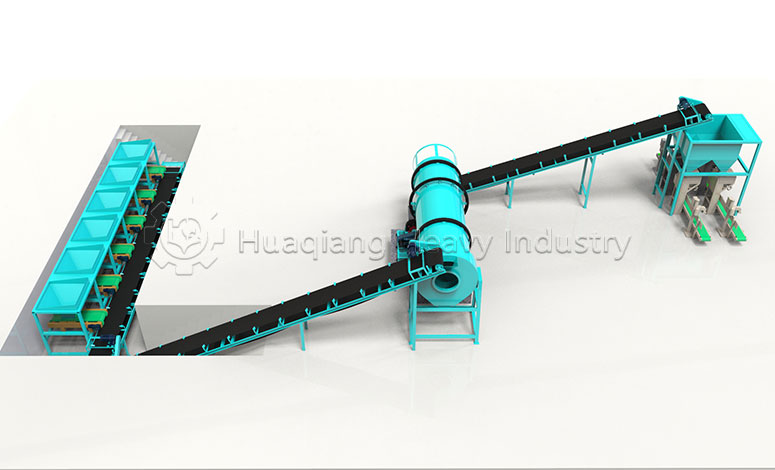

Trough-type compost turners are core equipment in the organic fertilizer fermentation process, and their operating efficiency directly affects the composting cycle, maturation quality, and production efficiency. Many production scenarios experience problems such as insufficient turning, high energy consumption, and frequent equipment failures. However, these issues can be significantly improved through scientific and standardized operation and management.

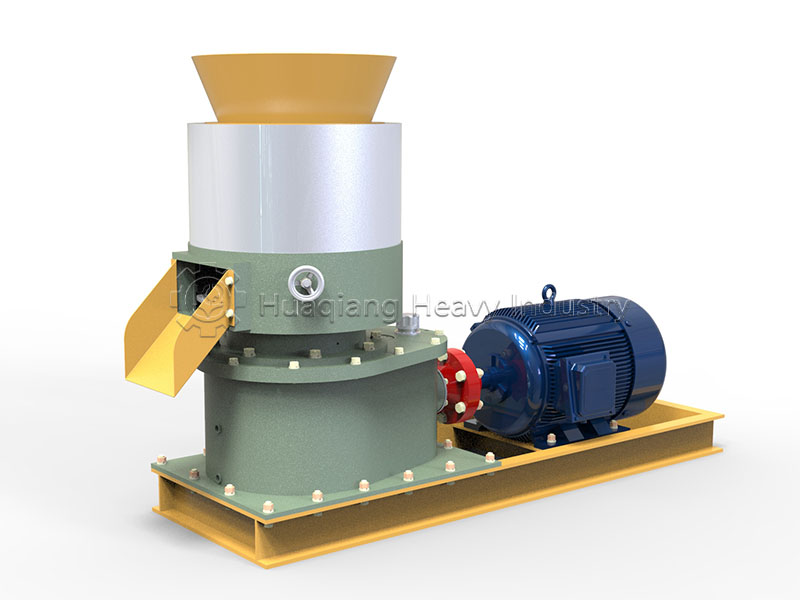

First, ensure proper raw material pretreatment. The moisture content, particle size, and ratio of composting raw materials are fundamental. The moisture content of the materials should be controlled at 55%-60%, and a fertilizer crusher should be used to adjust the particle size of raw materials such as straw and livestock manure to 2-5 centimeters. Simultaneously, carbon and nitrogen sources should be mixed evenly in the correct proportions.

Second, standardize operating procedures and paths. During operation, a reasonable turning path should be planned, using a “reciprocating progressive” turning method to ensure that the material in each area is fully turned, avoiding missed or repeated turning. The speed of the trough-type compost turning machine should be controlled, and the rotation speed should be adjusted according to the width of the trough and the thickness of the material to ensure that the turning depth meets the standard (generally 30-50 centimeters).

Third, strengthen daily equipment maintenance. Regularly inspect key components of the compost turning machine, such as the blades, tracks, and transmission system. Replace worn blades promptly and tighten loose connections; add lubricating oil as required to ensure smooth operation of the transmission system.

Finally, accurately match the operating frequency. Adjust the turning frequency according to changes in composting temperature. During the high-temperature fermentation period (55-65℃), turning can be performed 1-2 times a day; when the temperature is below 50℃, the frequency should be appropriately reduced. Accurately matching the frequency can meet the oxygen demand of microbial fermentation without wasting energy due to excessive turning.