Flat die pelleting machines: A technological breakthrough in high-pressure extrusion molding

In the field of organic fertilizer granulation technology, the flat die pelleting machine adopts a technical approach different from traditional granulation methods. Through high-efficiency vertical extrusion, it transforms powdered organic raw materials into solid and dense granular products, demonstrating unique process value.

In practical production, the flat die pelleting machine exhibits significant structural advantages. Its relatively compact mechanical structure requires less floor space, and power transmission is more direct and efficient. This design not only reduces the site requirements for equipment installation but also results in superior energy efficiency.

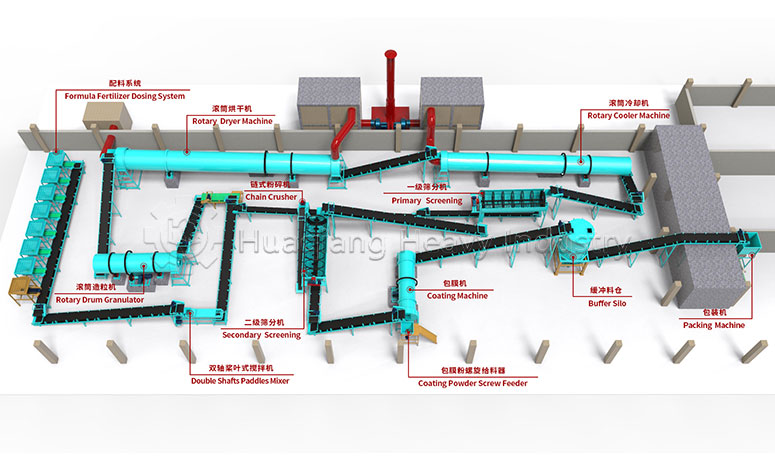

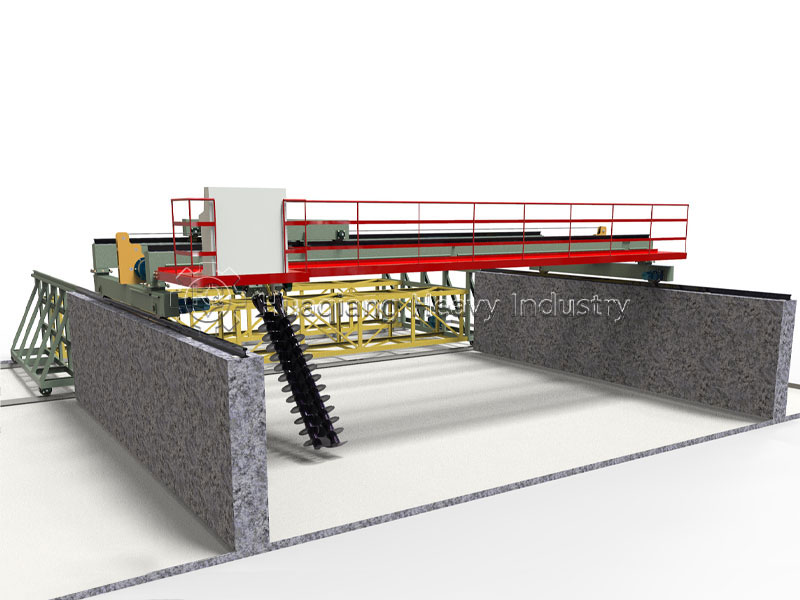

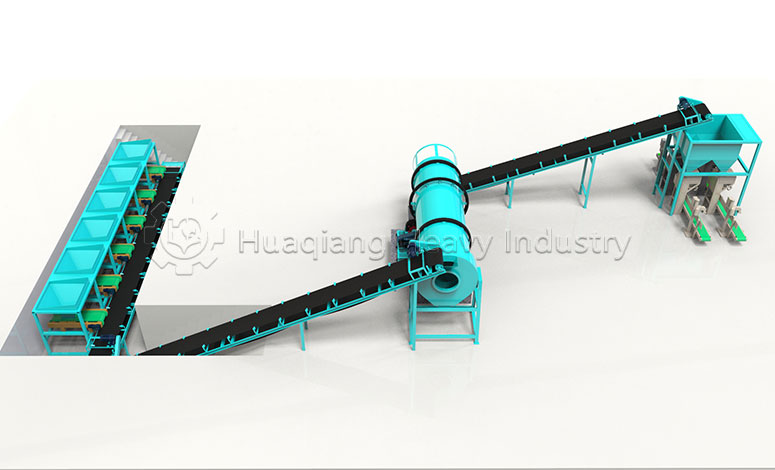

From the perspective of system integration, the flat die pelleting machine plays a crucial role in modern organic fertilizer production lines. It can be efficiently connected with upstream fermentation equipment and downstream drying and screening equipment, forming a complete production process loop. As a key molding unit in the organic fertilizer production equipment system, its stable performance and low maintenance requirements ensure the continuous and stable operation of the entire production line.

Particularly noteworthy is the equipment’s high tolerance for raw material moisture content. Even under relatively low humidity conditions, it can maintain good molding effects, providing greater operational flexibility for moisture control during the production process and reducing the impact of fluctuations in raw material humidity on production stability.

With its unique technical characteristics and reliable production performance, the flat die pelleting machine enriches the technical options for organic fertilizer granulators and, through continuous technological optimization, drives the entire organic fertilizer production equipment industry towards a more efficient and professional direction.