The role of uniform feeder in fertilizer production line

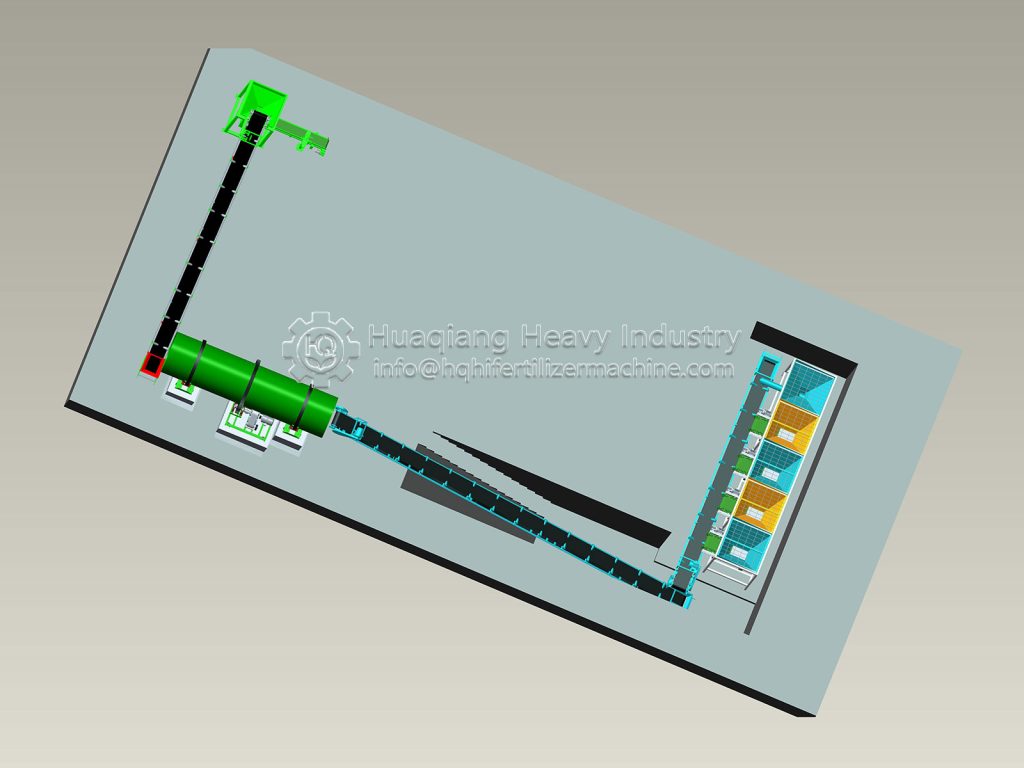

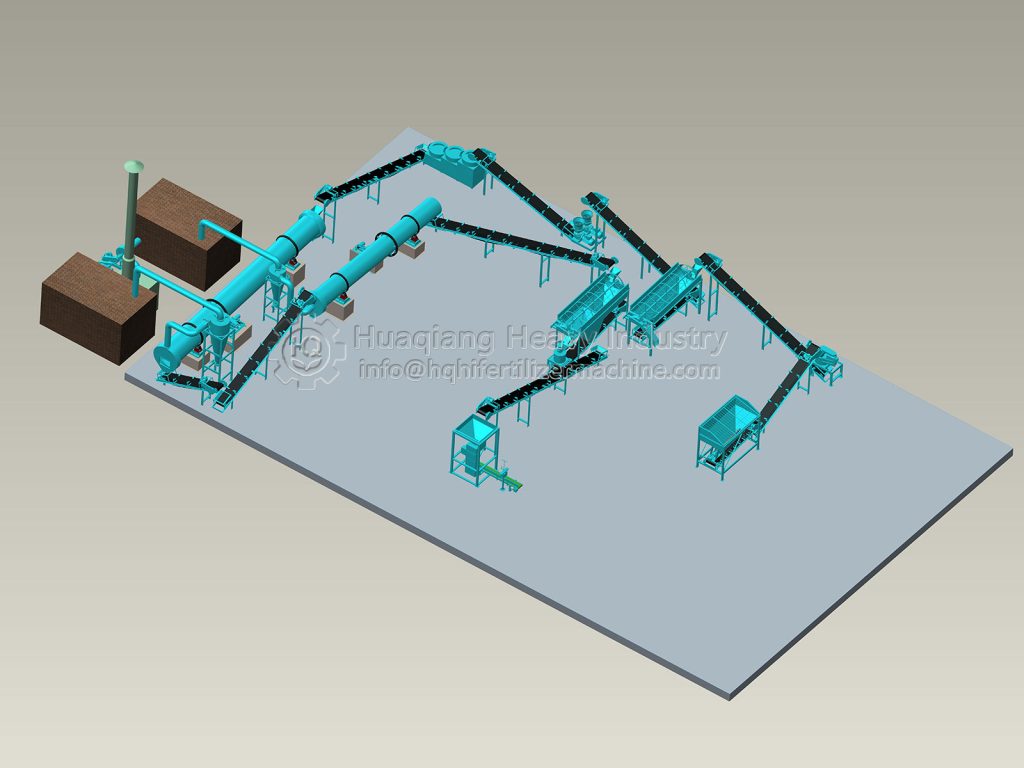

In the continuous process of fertilizer production, the uniform feeder is the “nerve center” to ensure the coordinated operation of all links. Whether in compound fertilizer production line or organic fertilizer production line, it can improve the stability of raw material supply by more than 50%, and reduce product quality fluctuations from the source.

The uniform feeder adopts a design combining spiral conveying and frequency conversion speed regulation. The conveying screw is made of wear-resistant alloy material, which can adapt to raw materials with different physical properties such as urea granules, phosphate rock powder, fermented organic fertilizer, etc. The feeding amount can be set with an accuracy of ±2%. It can automatically adjust the conveying speed according to the needs of subsequent crushing, mixing, granulation and other processes to avoid raw material accumulation or feed interruption.

In the compound fertilizer production line, it can accurately convey basic raw materials such as nitrogen, phosphorus, and potassium according to the ratio, so that the nutrient deviation in the mixing link is controlled within 2%, which is much better than 8% of manual feeding. When handling wet organic fertilizer raw materials, its anti-blocking spiral structure combined with the vibration device can effectively avoid material adhesion and blockage, ensuring that the feeding amount per minute is stable at more than 98% of the preset value.

Compared with traditional feeding equipment, the uniform feeder does not require frequent manual adjustment, can reduce 80% of operational intervention, and reduce energy consumption by 30%. The material level sensor equipped with the equipment can monitor the inventory of the silo in real time, automatically start and stop the feeding, and realize unmanned continuous operation.

Whether it is connected to the crushing equipment or the mixer, the uniform feeder can lay a good foundation for the subsequent processes through the stable supply of raw materials. Choosing an appropriate uniform feeder can make the fertilizer production process smoother, the product quality more stable, and demonstrate the core value in large-scale production.