What kind of organic fertilizer equipment and process customers choose, the investment and production costs and benefits are different. Therefore, how to choose a reasonable process configuration is an important factor to effectively reduce the cost of equipment when inspecting the production process equipment. This paper introduces the process of organic fertilizer production line with an annual output of 20000 tons designed by Tianci factory.

Process of organic fertilizer production equipment of each process system

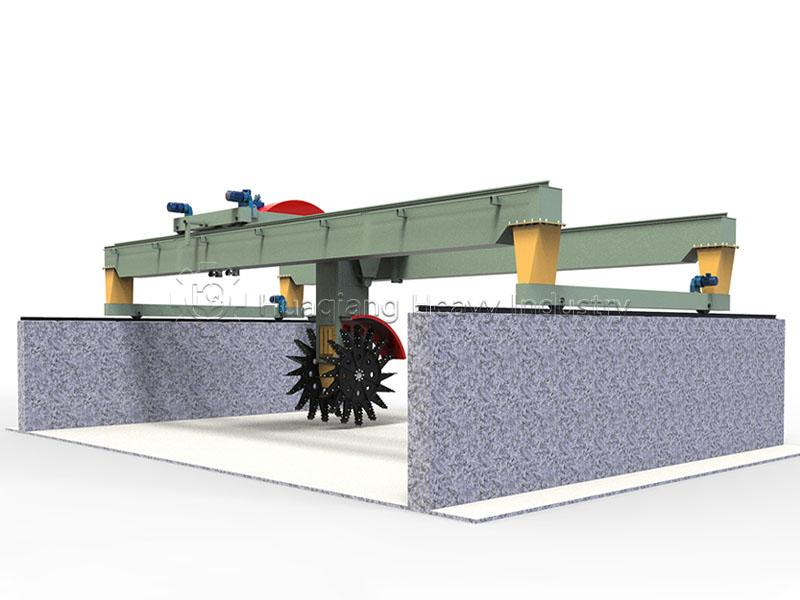

① Fermentation system: the fermentation system of organic fertilizer equipment process consists of biological deodorizer, mixing mixer, special compost turner machine and electric automatic control system.

② Drying system: the main equipment includes belt conveyor, rotary dryer, cooler, induced draft fan, hot blast furnace, etc.

③ Deodorization and dedusting system: composed of settling chamber, dedusting chamber, etc.

④ Pulverizing system: including new semi wet material pulverizer, LP chain crusher or cage crushing machine, etc.

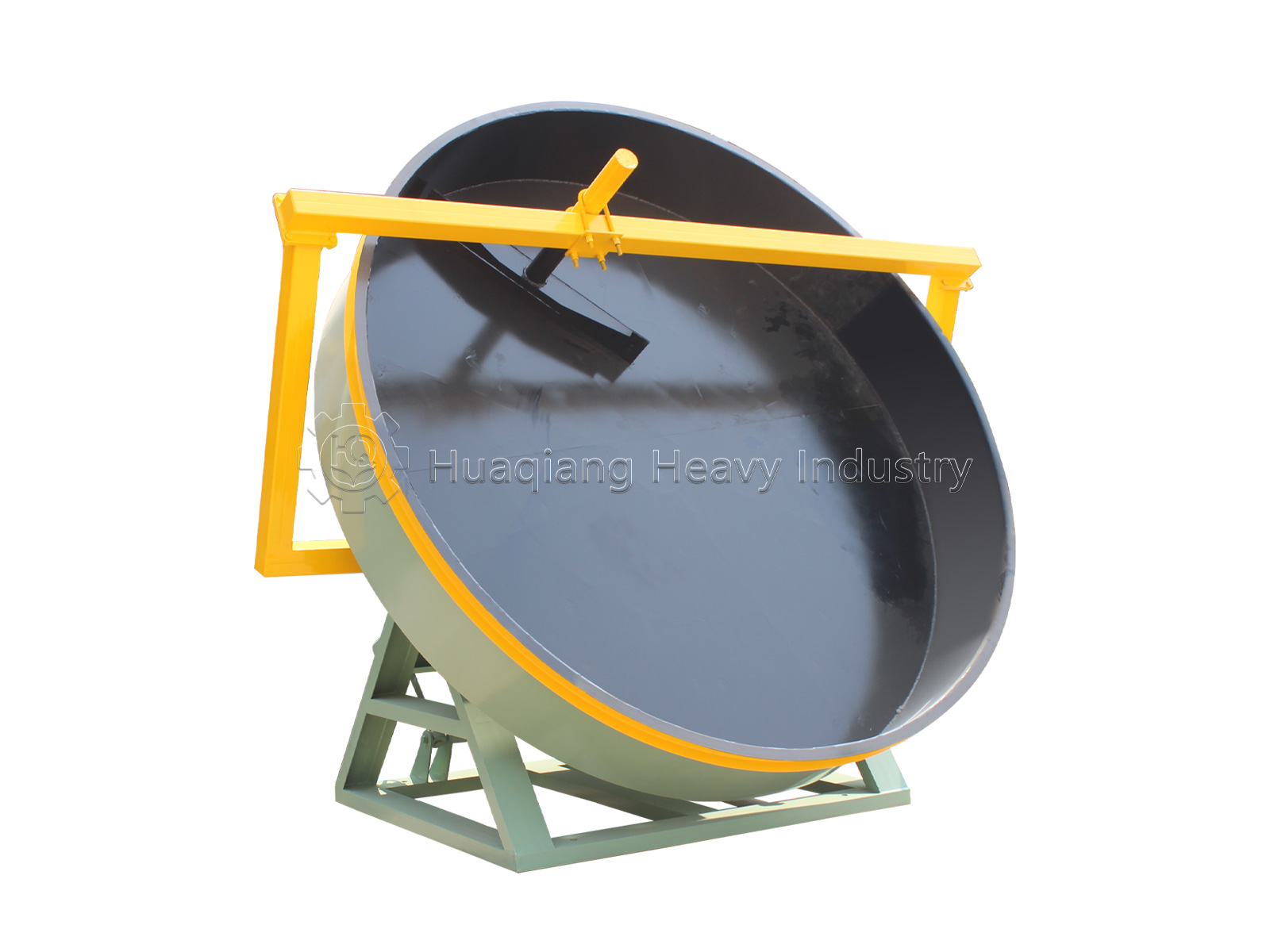

⑤ The batching system includes automatic electronic batching system, disc feeder and vibrating screen. The batching equipment can be configured with 6-8 kinds of raw materials at a time.

⑥ The mixing system consists of optional horizontal mixer or disc mixer, vibrating screen, mobile belt conveyor, etc.

⑦ The granulator equipment needed for fertilizer granulator system shall be set according to the raw materials and process. The pelletizer can be selected as follows: double roller granulator, organic fertilizer and compound fertilizer combined granulator, pan granulator, new type organic fertilizer granulator, flat die pellet mill, rotary drum granulator, ball shaping machine, etc.

⑧ Drying system: the organic fertilizer drying system consists of a rotary dryer and a cooler.

⑨ Screening and coating system: it is mainly completed by the roller screen, which can be equipped with primary screen and secondary screen, so that the yield is higher and the particles are better. After screening, the fertilizer coating machine can be used to ensure that the fertility is not released.

⑩ Finished product packaging system generally includes electronic quantitative packaging scale, silo, automatic sewing machine, etc. In this way, automatic and non-intermittent production of organic fertilizer equipment can be realized; the conveyor system mostly uses belt conveyors and screw conveyors.

The raw material has good comminution fineness, which is beneficial to the pelletizing processing of disc granulator machine and other equipment. During the operation of the organic fertilizer production line, considering that the high fineness of the pulverizer will produce certain dust pollution, the dust treatment of the pulverizer should also develop perfect measures to ensure that there is a good environmental condition in the production workshop and a good working environment for the operators.

In the dedusting system, the small production line can adopt the cyclone deduster series products, so as to facilitate the collection and recovery of materials. Cyclone dust collector will not produce high temperature and condensation phenomenon, and the equipment price is relatively low, which saves the equipment cost very well, and is the ideal product of proportioning dust removal system. The process of organic fertilizer production line with an annual output of 20,000 tons is more cost-effective to build a dust removal room, with better dust removal effect, high efficiency and long service life.