Detailed explanation of the mixing process in an NPK blending fertilizer production line

In the production of NPK blended fertilizer, the mixing process is the core link that determines the quality of the final product. Its goal is to uniformly blend basic fertilizers such as nitrogen (N), phosphorus (P), and potassium (K) from different sources, ensuring that each fertilizer particle has a consistent nutrient ratio.

1.Raw Material Pretreatment is Fundamental

The physical properties of the raw materials are crucial before they enter the fertilizer mixer machine. The particle size of each elemental fertilizer must be highly matched; this is a prerequisite for achieving uniform mixing and preventing nutrient separation (segregation) during subsequent transportation and use. Moisture content also needs to be strictly controlled to prevent material agglomeration.

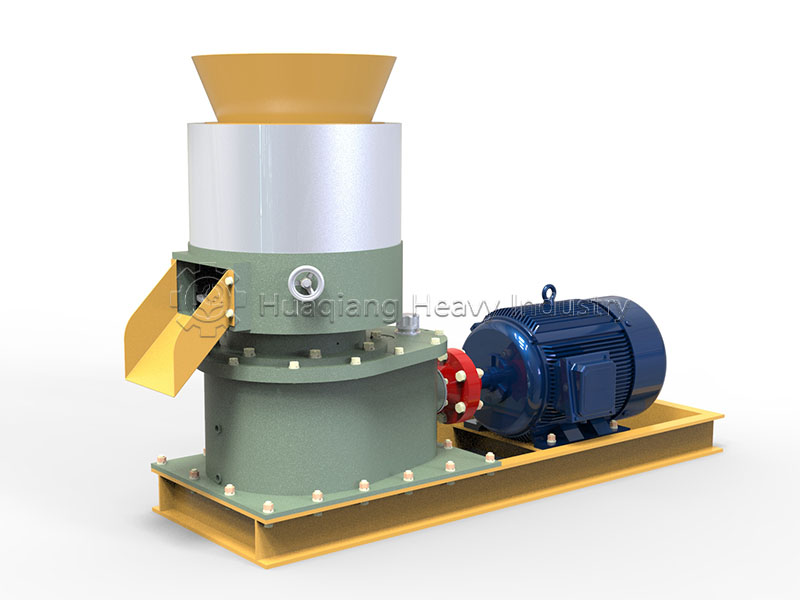

2.Efficient Mixing is Key

The core equipment is a double axis paddle mixer. When the material enters, two shafts rotating at specific angles and speeds drive the paddles, causing the material to undergo multi-dimensional composite motion within the machine. This includes both radial circular motion and axial lateral movement. This intense convection, shearing, and diffusion action can thoroughly interweave the various raw materials in a very short time (usually 2-4 minutes).

3.Precise Control as a Guarantee

The entire mixing process is precisely controlled by an automated system. Parameters such as feeding sequence, mixing time, and main unit load are monitored and recorded in real time. This precise control eliminates human error, ensuring the stability and reproducibility of each batch of product.

In short, the seemingly simple mixing process is actually the culmination of science, technology, and experience. It ensures that the NPK blending fertilizer production line can accurately deliver its nutrient formula, laying a solid foundation for balanced crop nutrition.