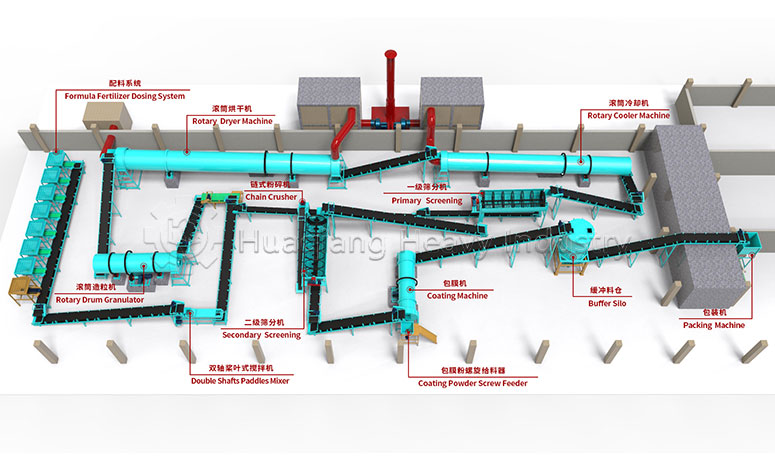

Synergistic application of NPK fertilizer production lines and BB fertilizer mixers

NPK fertilizer production lines are crucial for compound fertilizer production. As a key piece of equipment, BB fertilizer mixers, when integrated with the production line, significantly improve overall production efficiency and product quality. NPK fertilizer production involves processes such as raw material crushing, mixing, granulation, and drying. The mixing stage directly impacts the nutrient balance of the final product, and BB fertilizer mixers are a perfect fit for this requirement.

In the production line, raw materials processed by the fertilizer crusher are delivered to the BB fertilizer mixer via a fertilizer conveyor. Upon startup, the drive system drives the mixing shaft and blades, evenly mixing nitrogen, phosphorus, and potassium, laying a solid foundation for the subsequent granulation process. Inhomogeneous mixing can result in significantly different nutrient distributions in the granulated fertilizer, impacting product quality.

The BB fertilizer mixer’s control system can be linked with the overall production line control system to synchronize parameters such as mixing speed and time, ensuring a smooth production process. After mixing, the uniform raw materials are discharged through the discharge port and sent to the granulator by conveyor. It works efficiently with subsequent equipment such as dryers and coolers to form a complete NPK fertilizer production chain, helping companies achieve large-scale, high-quality production.