Building the core strength for efficient and environmentally friendly fertilizer production

Under the general trend of green agricultural development, the demand for organic fertilizers is growing due to their ability to improve soil quality and enhance crop quality. Efficient organic fertilizer production equipment has become crucial for achieving large-scale and standardized production.

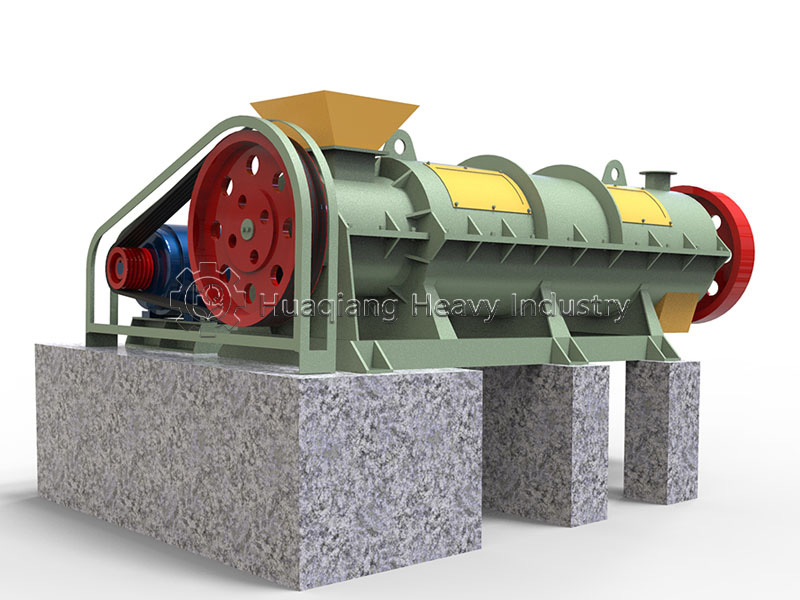

Organic fertilizer production equipment comes in a wide variety of types, covering the entire production process. Among them, the organic fermentation compost turning machine is the core of the initial stage. It can regulate temperature and aeration by turning the fermented materials, accelerating the decomposition of raw materials such as straw and livestock manure, preventing odor generation, and laying a high-quality foundation for subsequent production. In the processing stage, the fertilizer crusher can crush the decomposed materials to a uniform particle size, solving the problem of clumping; subsequently, the fertilizer mixer machine can accurately mix various auxiliary materials to ensure balanced nutrition in the organic fertilizer.

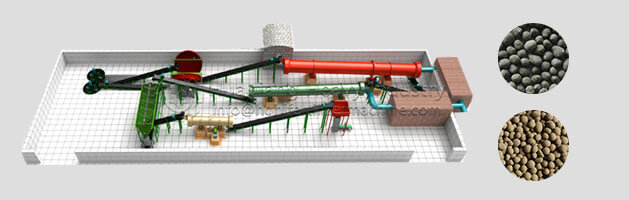

The granulation stage relies on organic fertilizer granulators, such as disc granulators and rotary drum granulators, which can process the mixed materials into granules. This not only facilitates storage and transportation but also controls the nutrient release rate. After granulation, the fertilizer dryer and cooler work together to remove moisture from the granules and stabilize their shape. The fertilizer screener machine then screens out products of the qualified particle size, and unqualified particles can be crushed and reused, reducing waste. Finally, the fertilizer packaging machine achieves automated quantitative packaging, improving production efficiency.

When choosing organic fertilizer production equipment, it is necessary to consider your own production capacity needs and raw material characteristics. For example, small farms can choose compact single-unit equipment, while large production enterprises are suitable for complete organic fertilizer production lines. High-quality equipment can not only increase output but also reduce energy consumption and pollution, meeting environmental protection requirements.