Organic fertilizer granulators: Diverse technological approaches enhance fertilizer value

In the organic fertilizer production sector, the diversified development of granulation technology offers a wealth of choices for enterprises of different sizes. From classic rotary drum granulators to innovative new type two in one organic fertilizer granulators, each type of equipment achieves the transformation of powdered raw materials into marketable granules in a unique way.

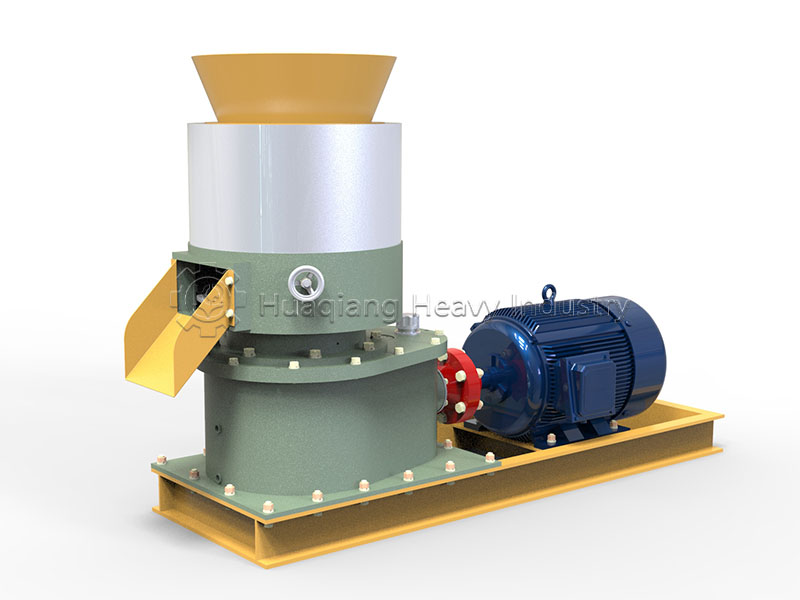

Rotary drum granulators hold an important position in the industry due to their gentle granulation method. This granulation method is particularly suitable for production scenarios requiring high granule roundness and is easy to integrate with other processes for continuous production. Ring die pelleting machines demonstrate strong forming capabilities. This equipment has wide adaptability to raw materials and can still ensure granule forming quality and output efficiency even when processing organic materials with high fiber content. Flat die pelleting machines are favored by small and medium-sized enterprises for their simple structure and convenient operation. This design effectively controls equipment investment costs while ensuring granulation quality.

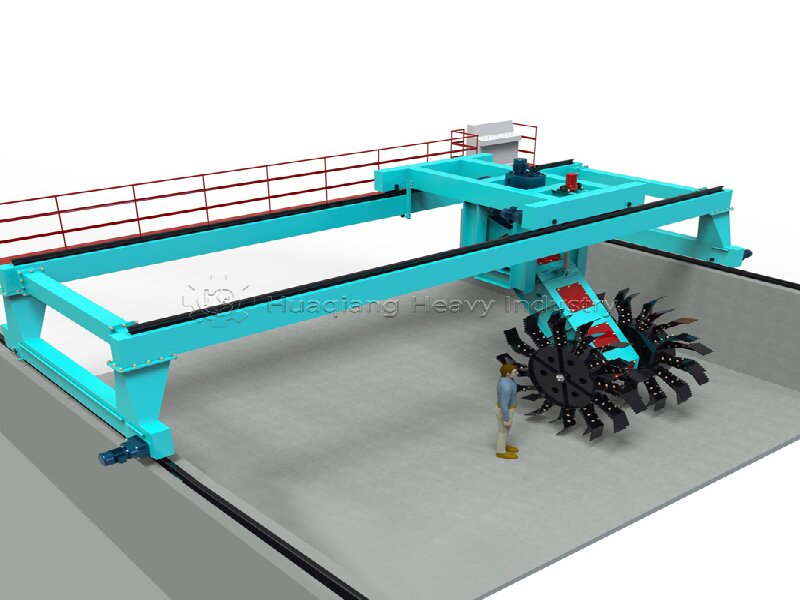

In recent years, the emergence of new type two in one organic fertilizer granulators has brought a brand-new solution to the industry. These devices integrate mixing and granulation functions, simplifying the process flow and making them particularly suitable for production sites with limited space.

Different types of granulation equipment have their own characteristics, and companies need to comprehensively consider factors such as raw material characteristics, product positioning, and production scale when making a selection. With the continuous upgrading of the organic fertilizer industry, granulation technology is also constantly improving.