Types of organic fertilizer materials and processing characteristics suitable for rotary drum granulators

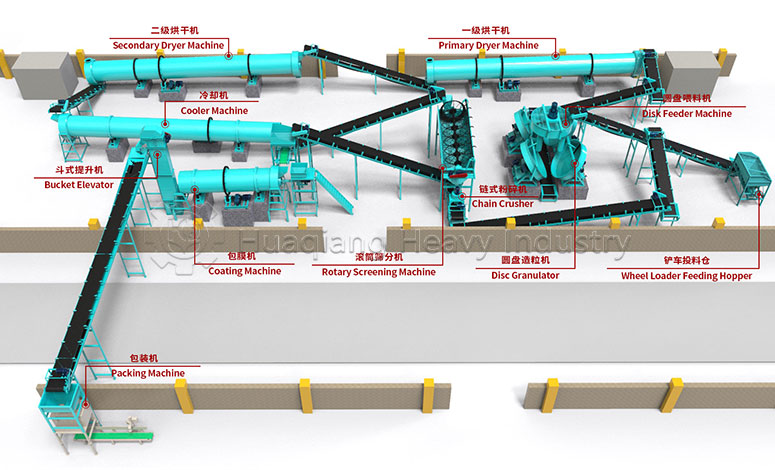

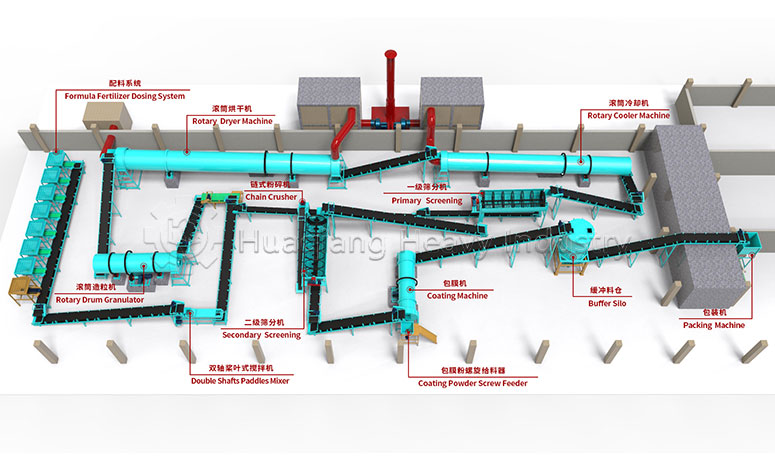

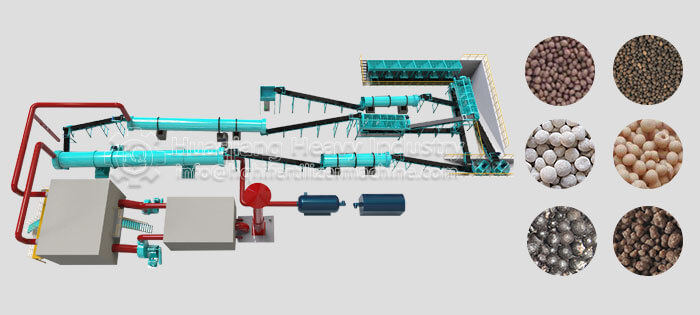

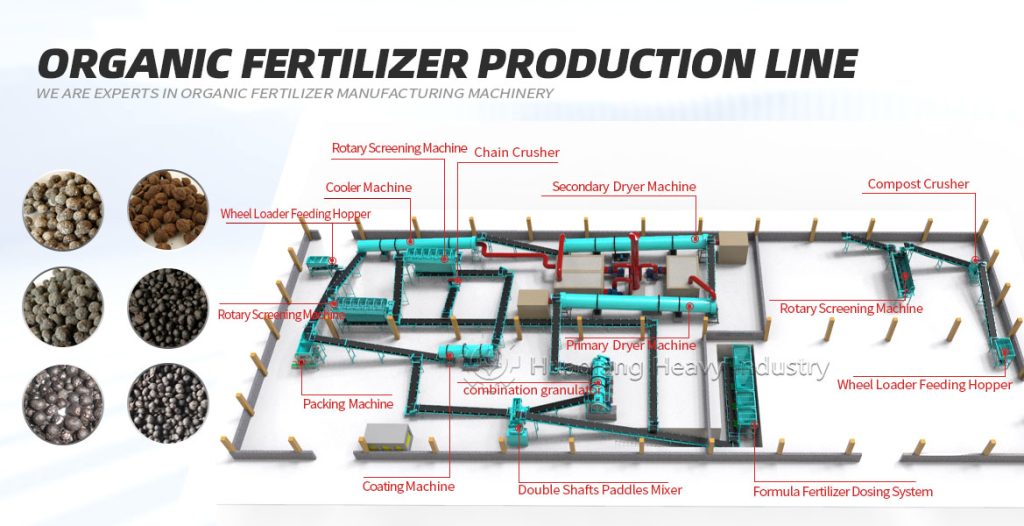

The rotary drum granulator, with its strong adaptability to various materials and high granulation rate, has become a core piece of equipment in organic fertilizer production lines. It can process organic materials from multiple sources, covering various fields such as livestock farming, agriculture, and industrial processing.

Livestock and poultry manure is the most common suitable material, including chicken manure, pig manure, cow manure, and sheep manure. These materials are rich in basic nutrients such as nitrogen, phosphorus, and potassium. After fermentation and composting, they have a loose texture and a certain viscosity, which meets the granulation requirements of the rotary drum granulator. The rotating agitation of the drum allows the manure material to be fully mixed with auxiliary materials, resulting in granules with moderate strength, effectively solving the problems of seedling burning and environmental pollution caused by the direct application of livestock and poultry manure.

Agricultural straw materials can also be processed by the rotary drum granulator, such as corn stalks, wheat stalks, and rice stalks. Straw is rich in cellulose and organic matter. After crushing and fermentation, it needs to be used in combination with viscous materials such as livestock and poultry manure. The rolling granulation of the drum allows the straw powder to be evenly coated and formed, which not only increases the organic matter content of the organic fertilizer but also realizes the resource utilization of agricultural waste.

In addition, the rotary drum granulator can also process industrial organic waste materials, such as distiller’s grains, vinegar residue, furfural residue, and pharmaceutical waste. These materials are rich in nutrients, but their composition is complex and their moisture content fluctuates greatly. The rotary drum granulator can adapt to the characteristics of different wastes by adjusting the rotation speed and material ratio, converting them into qualified organic fertilizer granules. At the same time, urban and rural organic waste such as kitchen waste and garden fallen leaves, after sorting and fermentation, can also be granulated and recycled through the rotary drum granulator.