As the rotary discs turn, the art of fertilizer formation unfolds

At large-scale fertilizer production sites, the large wheel compost turning machine is undoubtedly a unique sight. Unlike precision granulation equipment that focuses on shaping each individual particle, it silently plays a fundamental yet crucial role with its massive scale and repetitive rotation.

Its working scene is full of power. The huge rotating discs penetrate deep into the material pile, slowly but powerfully mixing, crushing, and oxygenating the fermenting raw materials through slow, forceful turning. This process, seemingly rough, actually lays a solid foundation for subsequent fine processing.

Once the raw materials have completed this “warm-up,” they undergo a transformation. At this point, the rotary drum granulator begins to display its charm. Inside the inclined drum, the material is continuously lifted and scattered as the drum rotates, gently tumbling and colliding, and then coagulating into round granules through its own hydration force.

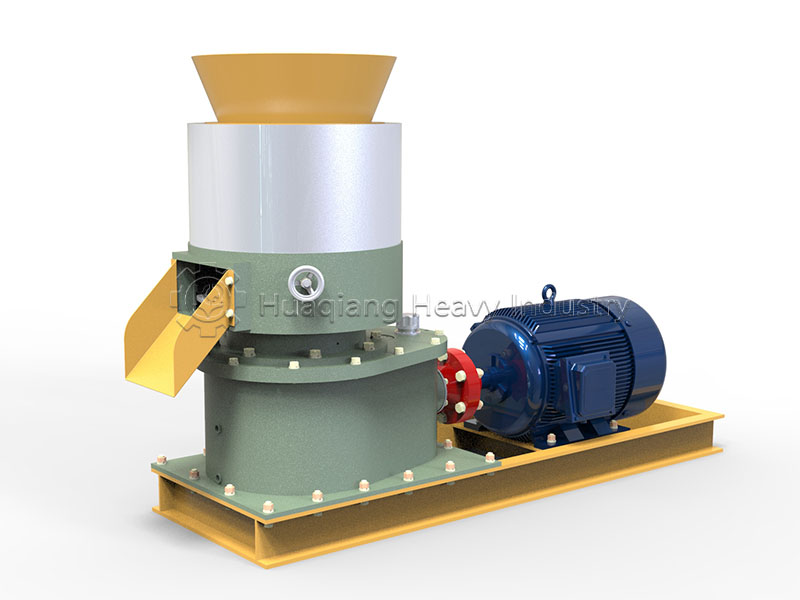

For scenarios requiring specific shapes or more complex formulations, the flat die pelleting machine offers another approach. It uses a die to forcefully compress the material, producing cylindrical granules with uniform particle size. This method is highly adaptable to various materials and produces high-density finished products, making it possible to meet diverse agronomic needs.

From the macroscopic preparation by the large wheel compost turning machine, to the dynamic pelletizing by the rotary drum granulator, and then to the precise shaping by the flat die pelleting machine, this is not simply a list of equipment, but a tightly linked process chain. Each component performs its specific function, working together to transform raw powder or waste into granules of commercial organic fertilizer that are easy to transport, store, and apply.