Composting materials guide: What you can and cannot compost!

The core of composting is the microbial decomposition of organic materials. Material selection directly determines composting efficiency, product quality, and whether unpleasant odors are produced. The key selection criteria are “easy decomposition, harmlessness, and suitable carbon-to-nitrogen ratio.” Below is a clear list of materials that can and cannot be composted.

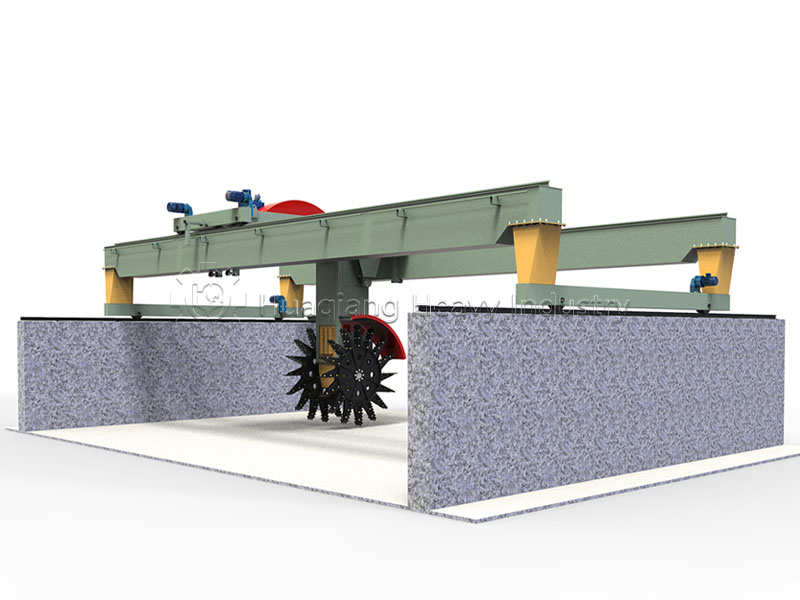

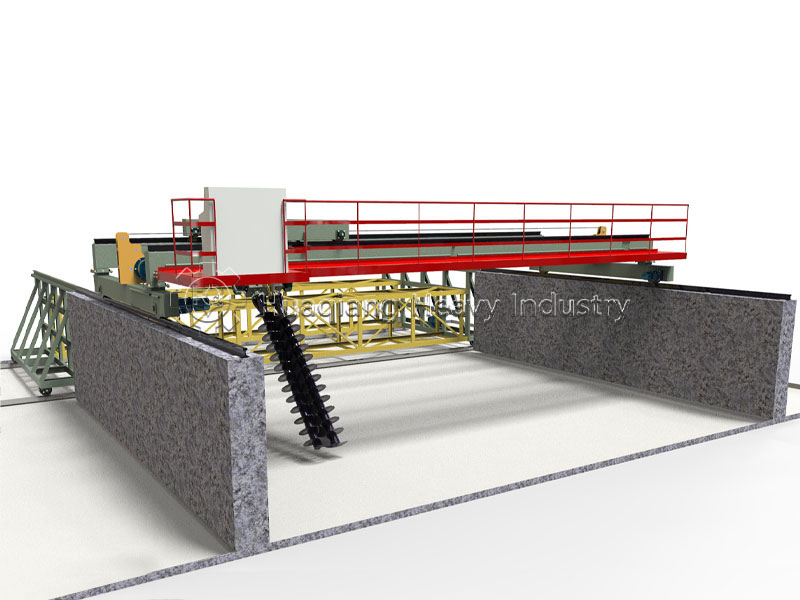

Compostable materials mainly consist of natural organic waste, divided into two categories: carbon-rich materials (straw, sawdust, fallen leaves) to supplement carbon elements and increase aeration; and nitrogen-rich materials (livestock manure, kitchen waste, fruit and vegetable scraps, mushroom residue) to provide nutrients and accelerate decomposition. A small amount of wood ash or composting inoculant can be added. Using an organic fertilizer composting machine for turning and mixing will improve the process. Windrow compost turning machines are suitable for large areas and heavy materials, while large wheel compost turning machines are suitable for small and medium-sized operations, helping to ensure even mixing of materials.

The following materials should absolutely not be composted: high-salt and high-fat foods (leftovers, fried foods, pickled foods), which will attract pests, produce foul odors, and inhibit microbial activity; and toxic and harmful materials (plastics, glass, straw with pesticide residues, chemical waste), which cannot be decomposed and will pollute the soil.

In addition, meat and bones decompose slowly and easily breed bacteria, so they are not recommended; large, hard objects that have not been crushed need to be crushed beforehand. After adding them, they can be turned and mixed using an organic fertilizer composting machine (both windrow and large wheel composting machines are suitable) to reduce ventilation obstruction; hazardous waste such as batteries is strictly prohibited to prevent heavy metal contamination.

In summary: Prioritize natural, easily decomposable organic waste, combine materials according to the carbon-to-nitrogen ratio, avoid prohibited materials, and use appropriate composting equipment to quickly produce high-quality, odor-free compost, contributing to soil improvement and crop growth.