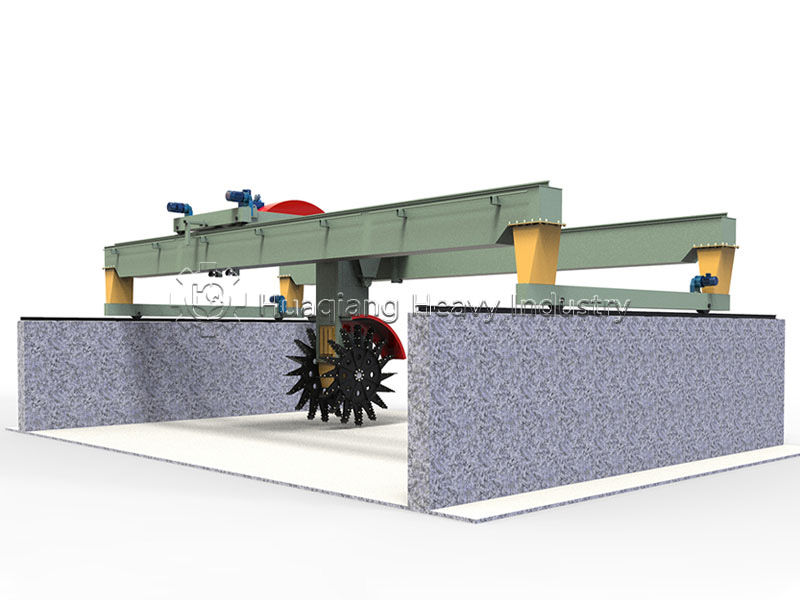

Key equipment for high-efficiency pretreatment in bio-organic fertilizer production lines

In the field of organic waste resource utilization, sticky and moist livestock and poultry manure, pasty kitchen waste, and insufficiently dried agricultural straw often pose pretreatment challenges due to their high moisture content and tendency to stick together. As an important member of the bio-organic fertilizer equipment system, the widespread application of half-wet material crushers has successfully transformed this technical bottleneck into a starting point for high-efficiency production.

The core capability of the half-wet material crusher lies in its excellent “moisture resistance” and “anti-clogging” design. It can efficiently process viscous materials with a moisture content of 30%-50%. This pretreatment not only solves the problems of subsequent conveying and mixing but also creates an ideal material state for deep fermentation.

In a complete bio-organic fertilizer production line, this equipment plays a crucial “pioneer” role. Its refined processing of raw materials directly improves fermentation efficiency and homogenization. The thoroughly crushed material has a significantly increased specific surface area, which is beneficial for the uniform inoculation and rapid reproduction of functional microorganisms.

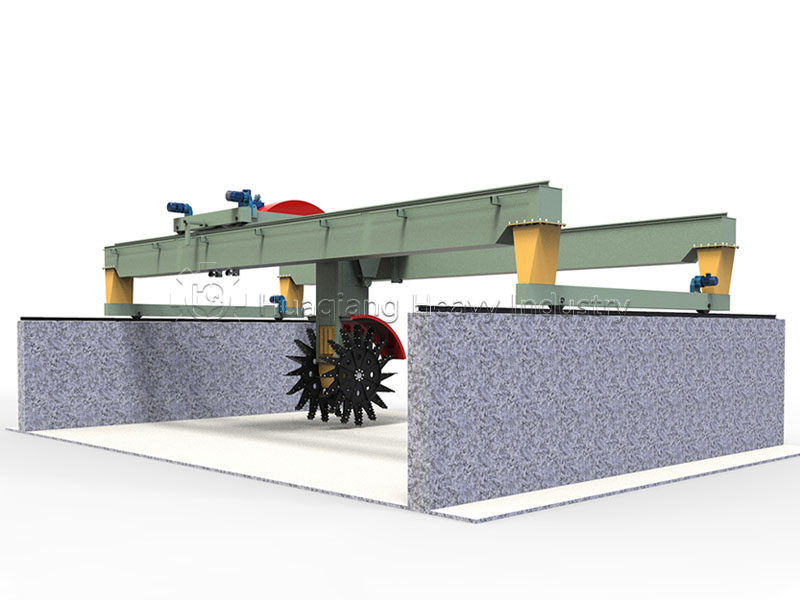

The raw materials processed by this equipment exhibit significant advantages when entering the new type organic fertilizer granulator. The uniform and fine material properties significantly improve the granulation rate and enhance particle compactness and uniformity during the granulation process.

From a broader perspective, the technological advancements in half-wet material crushers have greatly broadened the range of raw material choices for bio-organic fertilizer production lines. This not only improves resource utilization but also provides a reliable guarantee for the production of high-quality bio-organic fertilizer products.