Using a disc granulator to produce fertilizer to solve the pollution of poultry and livestock manure

For the topic of the recycling development of livestock and poultry manure, organic fertilizer equipment can be said to be the best equipment available now, because organic fertilizer equipment can effectively treat livestock and poultry manure into organic fertilizer in the current market, achieving the goal of recycling and not wasting resources. Moreover, we all know that livestock and poultry manure causes significant environmental and air pollution, So the organic fertilizer equipment that can handle livestock and poultry manure has been widely recognized by people. The country is also vigorously promoting the use of organic fertilizers, and organic fertilizer equipment can precisely turn livestock and poultry manure into organic fertilizer, which also proves that the future market prospects for organic fertilizer equipment are very broad.

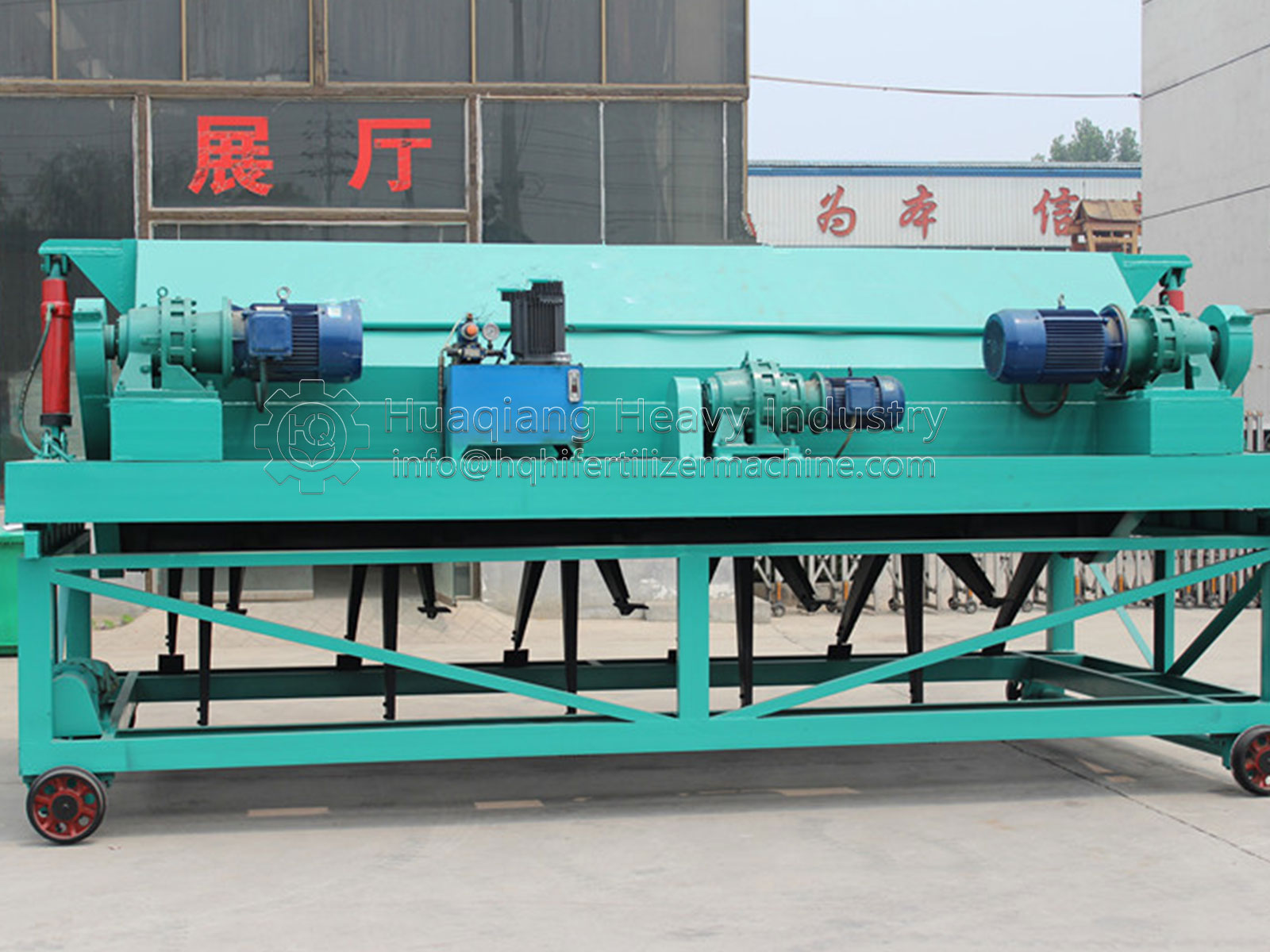

Organic fertilizer disc granulator: also known as ball disc, the angle of the granulation disc adopts a circular arc structure, and the ball forming rate can reach over 93%. The granulation plate is equipped with three discharge ports, which facilitate intermittent production operations, greatly reducing labor intensity and improving labor efficiency. This machine has the advantages of uniform granulation, high balling rate, stable operation, sturdy and durable equipment, and long service life, and is highly praised by users.

Organic fertilizer equipment is used to granulate various organic matter after fermentation, breaking through the conventional organic matter granulation process. Before granulation, the raw materials do not need to be dried or crushed, and spherical particles can be processed directly with ingredients, which can save a lot of energy. Traditional methods of fertilizing with nutrients such as manure and garbage not only cause certain harm to the environment, but also fail to fully utilize their effects. With the increasing use of organic fertilizers, compound fertilizers, microbial fertilizers, and fertilizers, more and more people are aware of the benefits of organic fertilizers on the soil. Organic fertilizers have gradually gained recognition from more people, and organic fertilizer equipment has gradually entered people’s daily life and production, Let more people know that organic fertilizer equipment is used for professional production of organic fertilizers.

We have always followed the path of sustainable development in our development strategy, and organic fertilizer equipment is increasingly popular and recognized by farmers. We believe that we can fully consume green and pollution-free products soon.

.jpg)

.jpg)

.jpg)