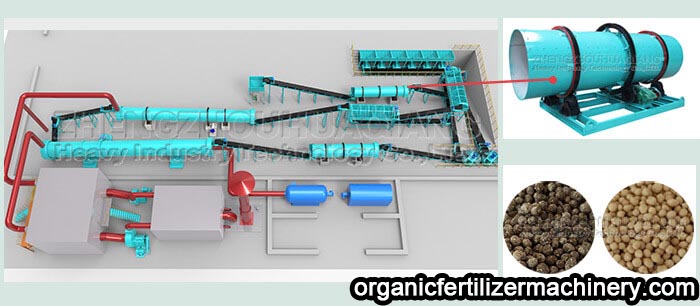

Matters needing attention in production of rotary drum granulator

The rotary drum granulator has been carefully studied by the technical department of the market demand, analyzed the actual situation of the user, timely and effective adjustment, research and development of the compound fertilizer equipment that is more in line with the market and more closely related to the user.

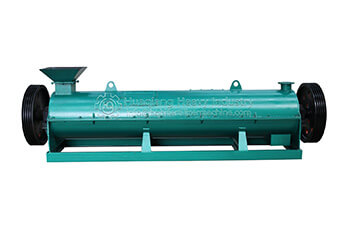

Rotary drum granulator is one of the key equipment in compound fertilizer equipment industry, which is suitable for cold and hot granulation and large-scale production of high, medium and low concentration compound fertilizer. The special rubber plate lining or acid resistant stainless steel lining plate is used in the barrel of the fertilizer granulation machine, which realizes the automatic scar removal and tumor removal, and cancels the traditional scraper device. The machine has the characteristics of high ball forming strength, good appearance quality, corrosion resistance, wear resistance, low energy consumption, long service life and convenient operation and maintenance.

Rolling belt sliding

Causes: ① the concave joint side of rolling belt is not clamped. The treatment method is to clamp the side of drum granulation roller belt and concave joint.

② It is not clamped with rolling belt and concave joint in radius direction. The fertilizer granulation machine can be clamped by base plate or clamp, but excessive or uneven clamping must be paid attention to, and the tension is easy to cause the body to jump and vibrate and cause accidents.

Body dislocation

Causes: ① wear of supporting roller. The supporting roller can be repaired or replaced according to the wear degree

② The block wheel is worn. The rotary drum granulator needs to be repaired, moved or replaced according to the wear degree.

Gear misalignment

Causes: ① the pinion is worn. Install the pinion in the opposite direction. If both sides are worn, replace the new gear for the drum granulator.

② The connection between the big gear and the cylinder was damaged. Adjust and adjust the connection, and make appropriate treatment when necessary.

Cylinder vibration

Causes: ① the connection between the supporting wheel device and the base is damaged. Adjust the connection and tighten the nut to make the supporting roller in the correct position.

② The side wear of roller belt in drum granulation. According to the wear degree, turn the side of the belt or replace it with a new one.

.jpg)

.jpg)

.jpg)

.jpg)