Key factors and advice for choosing an organic fertilizer screener machine

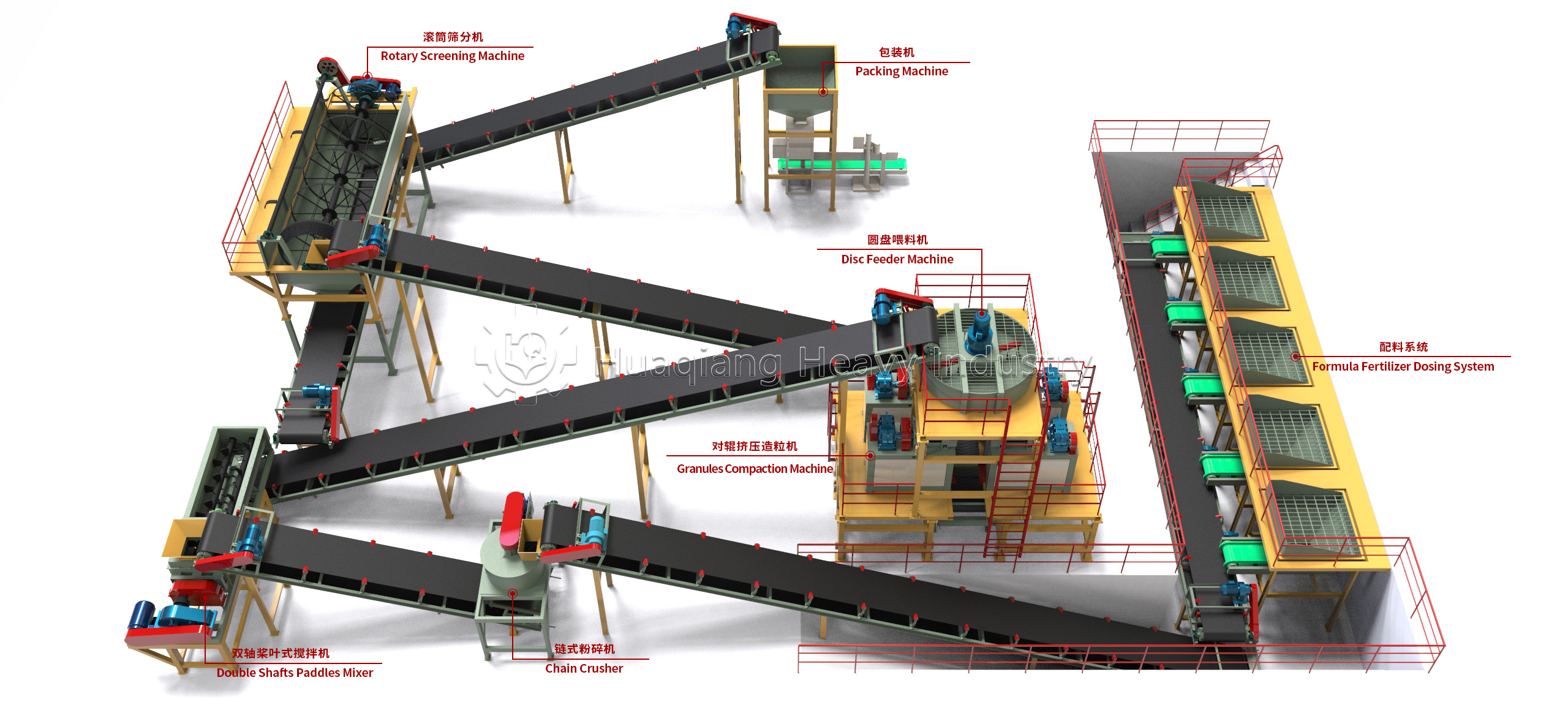

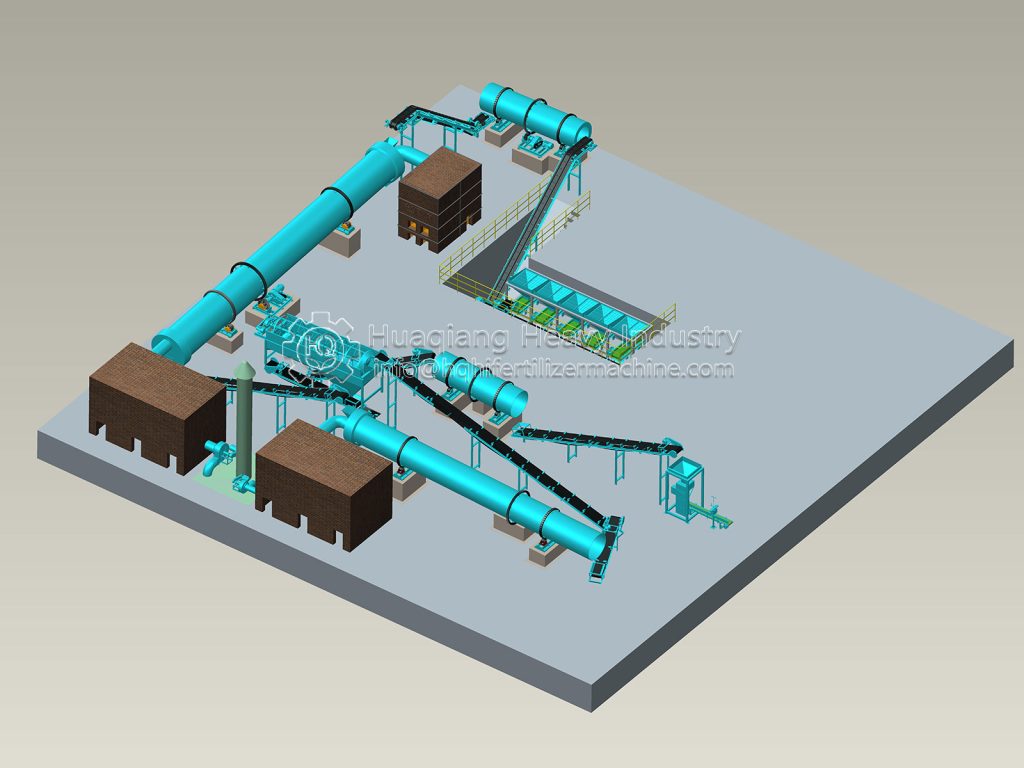

In organic fertilizer production, the fertilizer screener machine is one of the key pieces of equipment. It directly affects the quality of the final fertilizer product and its market competitiveness.

1.Choose the right screen type based on material characteristics

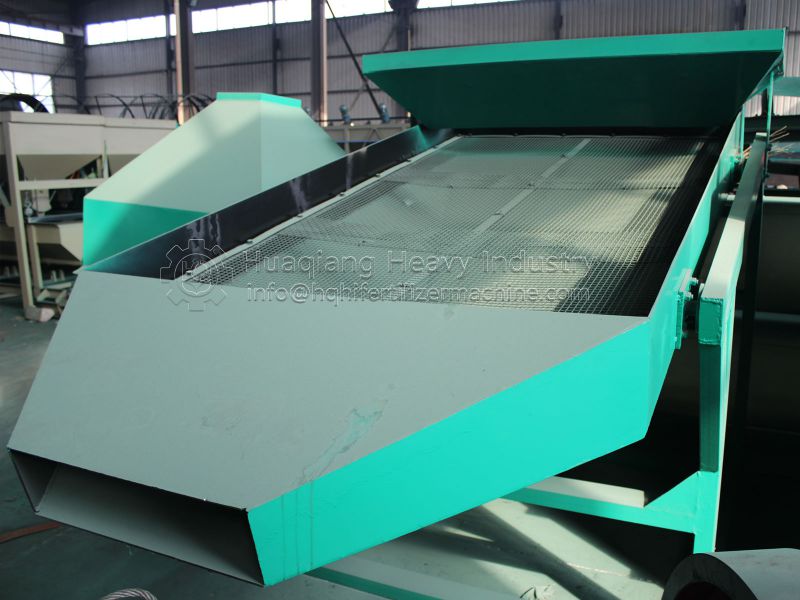

Rotary screener machine: Best for damp and sticky organic fertilizer materials. It offers high screening efficiency.

Vibration screener machine: Ideal for dry, granular fertilizers. It handles large volumes and provides good separation.

Probability screener machine: Designed for ultra-fine powdery fertilizers, with screening accuracy up to 95% or higher.

2.Focus on screening accuracy and processing capacity

Mesh size selection: For regular organic fertilizer, use 8-60 mesh, adjusting based on the final product requirements.

Match processing capacity: Ensure it fits the overall production line capacity to avoid bottlenecks.

Separation effect: Good equipment should achieve precise 2-3 level separation.

3.Anti-clogging design

Self-cleaning features: Should include bouncing balls or ultrasonic cleaning systems to prevent screen blockage.

Sealed structure: Helps control dust and improves the working environment.

4.Ease of maintenance

Modular design: Allows for quick screen replacement, reducing downtime.

Access points: Equipment should have easy access for inspection and routine maintenance.

5.Special function needs

Multi-layer screening: For producing different particle sizes simultaneously.

Smart monitoring: Equipped with online detection systems to track screening results in real time.

A high-quality fertilizer screener machine not only boosts product yield but also cuts production costs. So, when choosing one, consider material properties, screening accuracy, and machine design.