BB Fertilizer Mixers: Achieving Precise Nutrient Blending?

The Artisan of Physical Blending

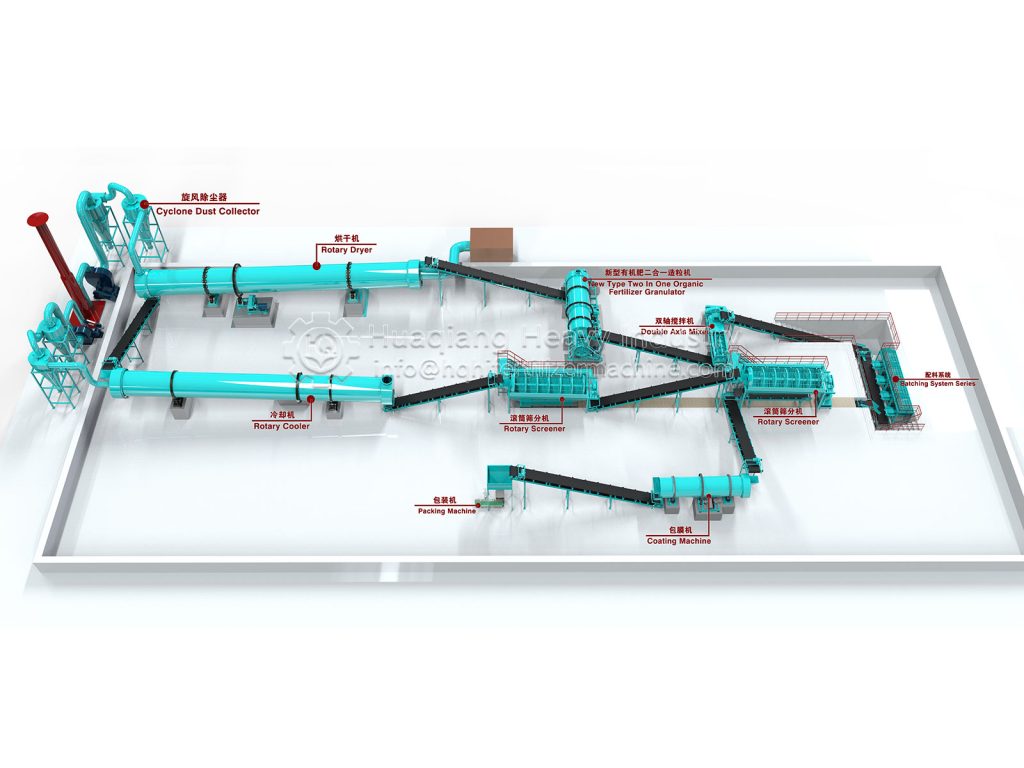

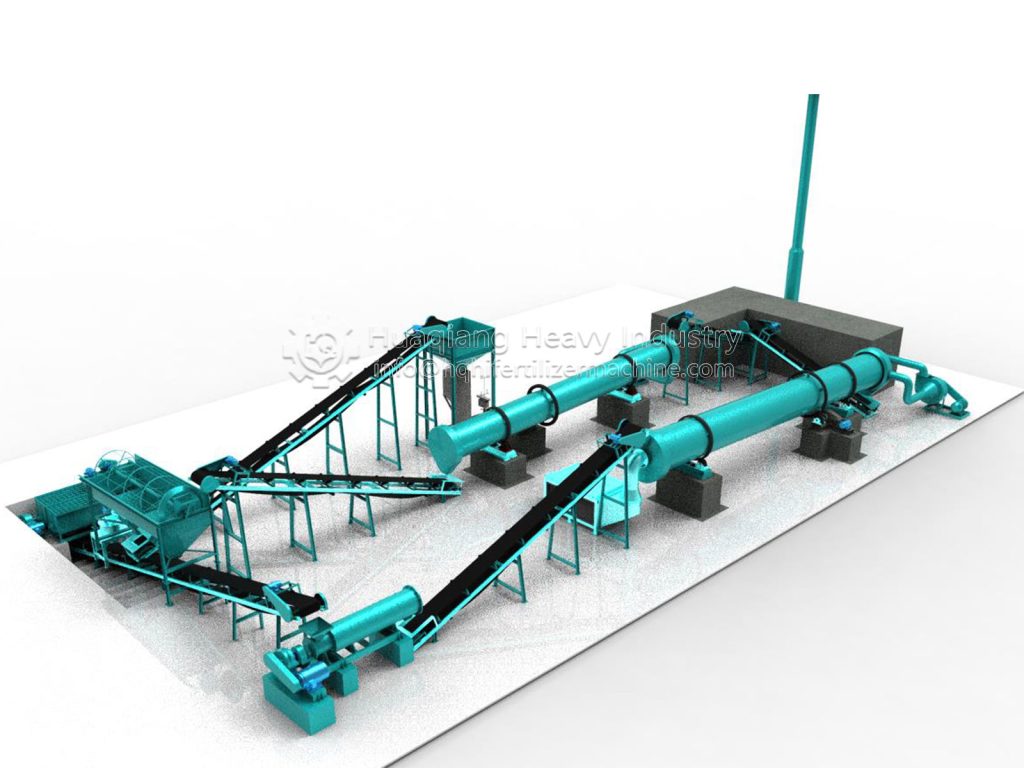

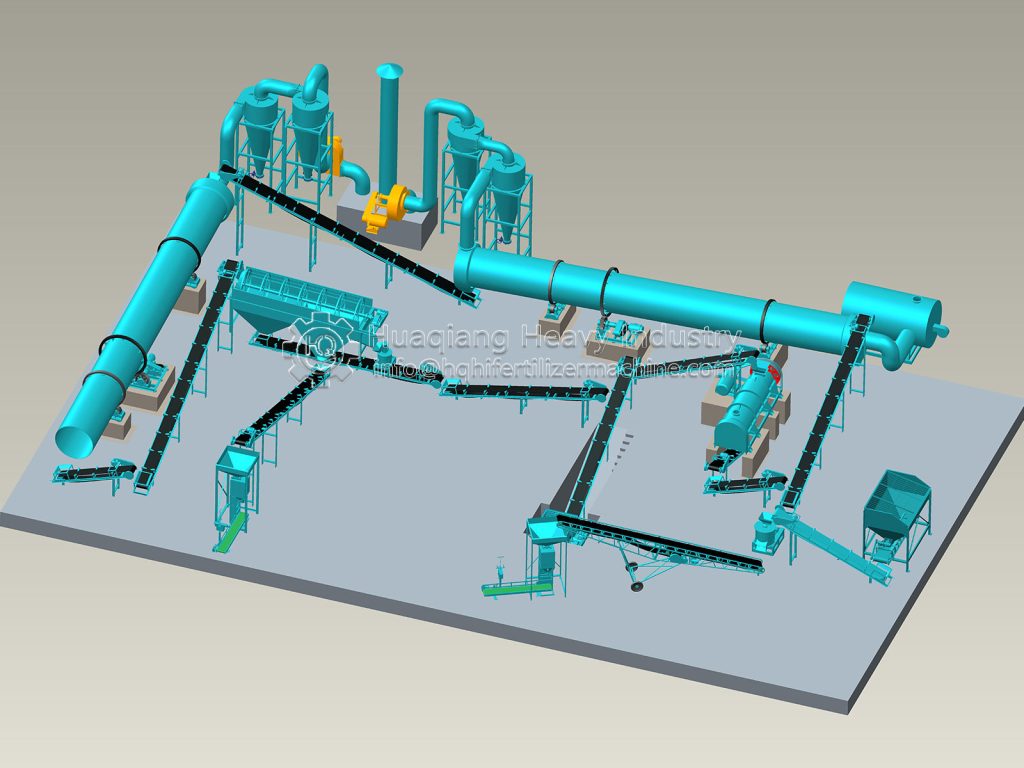

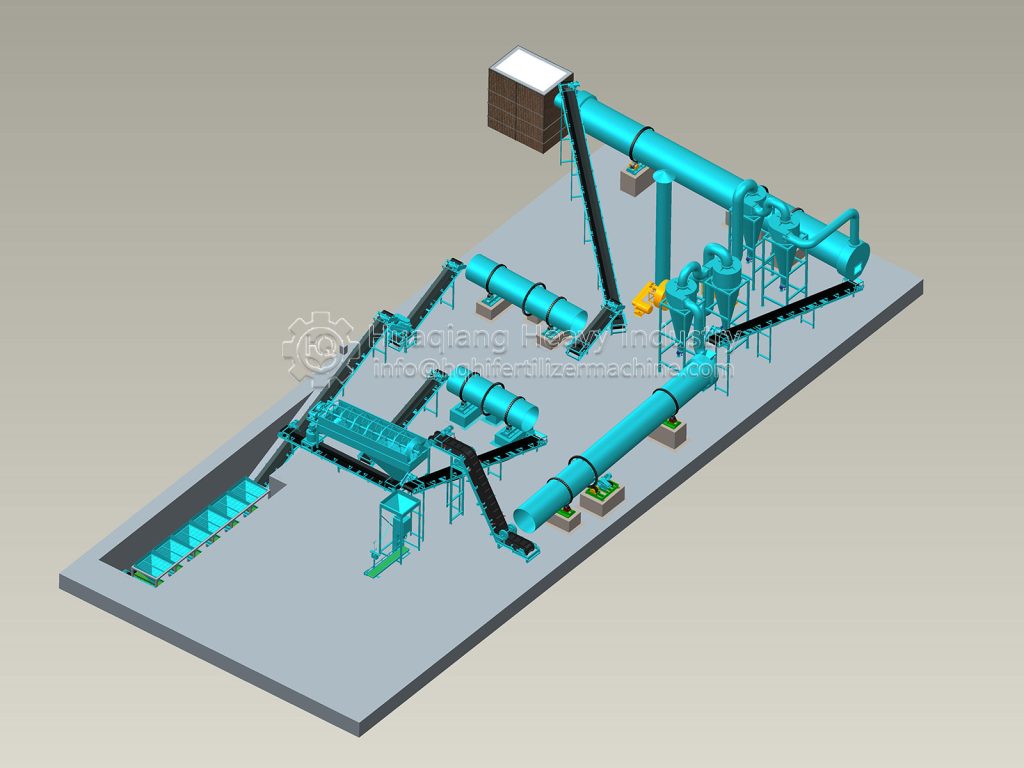

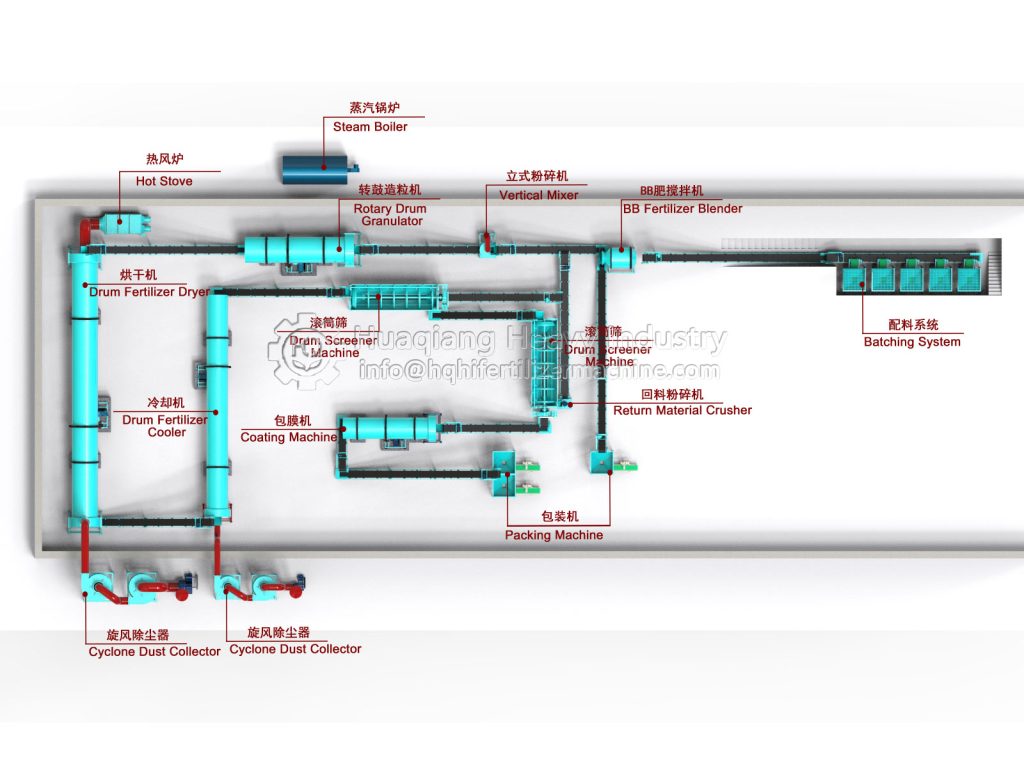

In modern agricultural production, BB fertilizer mixers—a specialized type of npk blending machine—play a vital role. These devices don’t rely on chemical reactions but instead use an ingenious physical npk manufacturing process to perfectly blend various nutrient materials like nitrogen, phosphorus, and potassium. This method, much like mixing colors on a painter’s palette, maintains the raw materials’ physical characteristics while achieving a molecular-level uniform distribution, setting it apart from traditional compound fertilizer equipment.

Did you know? High-quality BB fertilizer mixers can complete uniform blending of a batch in just 90 seconds, with mixing uniformity variation coefficients controlled within 5%, far superior to the industry standard requirement of 10%.

The Core Equipment for Precision Agriculture

Why is modern agriculture increasingly favoring BB fertilizer blending technology? The answer lies in three key advantages:

· Flexible Formulation – Allows immediate adjustment of nutrient formulas based on soil test results, enabling “soil-test-based” precision fertilization

· Nutrient Preservation – Physical blending causes no thermal damage, preserving all active ingredients in raw materials

· Cost Efficiency – Direct use of basic fertilizer materials eliminates chemical synthesis steps, reducing production costs by up to 30%

Particularly in cash crop growing regions, BB fertilizer mixers have become standard equipment in modern fertilizer plants, allowing farmers to customize exclusive nutrient packages according to crops’ growth stage requirements.

The Dawn of Intelligent Mixing

New generation BB fertilizer mixers are rapidly developing toward intelligent operation. Advanced models now feature:

· Automatic weighing systems – Precisely control the proportion of various raw materials

· Dust collection devices – Improve working environment and reduce material waste

· PLC control systems – Store hundreds of formulas with one-touch production mode switching

· IoT modules – Remotely monitor equipment status and production data

These technological innovations not only enhance production efficiency but also ensure every bag of BB fertilizer can accurately deliver the nutritional promise on its label, providing reliable support for sustainable development in modern agriculture.