How 15-15-6 Compound Fertilizer Affects Corn and Soil

In corn cultivation, proper fertilization is key to achieving high yields. The nitrogen-phosphorus-potassium compound fertilizer (15-15-6) is a common formulation, containing 15% nitrogen, 15% phosphorus, and 6% potassium. Understanding how this fertilizer affects soil and corn growth is crucial for farmers worldwide to achieve sustainable and productive agriculture.

Impact on Soil Chemical Properties

In the short term, the 15-15-6 compound fertilizer can effectively improve soil fertility. After application, the levels of available nitrogen and phosphorus in the soil increase significantly, providing sufficient nutrients for corn seedlings. The soil’s nutrient-holding capacity also improves slightly.

However, long-term, exclusive use of this fertilizer may pose challenges. Since its nitrogen is primarily in the ammonium form, its conversion in the soil releases acid, potentially leading to gradual soil acidification. This effect is more pronounced in sandy soils. Meanwhile, the phosphorus in the fertilizer is not very mobile. Long-term application can lead to accumulation in the soil; while it boosts phosphorus levels in the short term, excess can potentially reduce its availability.

Another point to note is the relatively low potassium content. Corn has a high demand for potassium during its mid-to-late growth stages, especially during the grain-filling period. Relying solely on this fertilizer may not fully meet this demand, affecting the crop’s stress resistance and grain plumpness.

Impact on Corn Plant Growth

Applying the 15-15-6 compound fertilizer significantly promotes corn growth. Plants become more robust, stalks thicker, and lodging resistance improves. Leaf area and chlorophyll content also increase, meaning a greater capacity for photosynthesis.

In terms of yield, proper application can increase corn production by 10%-25%. The synergistic effect of nitrogen and phosphorus in the fertilizer increases the number of kernels per ear and kernel weight, while also improving corn quality by boosting protein and starch content.

Balanced application is important. If applied only early in the season, it may lead to potassium deficiency later, affecting root penetration and disease resistance. Long-term, exclusive reliance on this chemical fertilizer might also make plants “lush but weak,” actually reducing their stress tolerance.

Optimizing Fertilization Recommendations

To maximize benefits and minimize potential problems, the following strategies are recommended:

Combine with Organic Fertilizers: Integrate chemical fertilizer with organic fertilizers (like composted straw or manure). This not only adds organic matter and improves soil structure but also helps mitigate soil acidification.

Supplement Potassium: Apply an appropriate amount of potassium fertilizer during key growth stages, such as the bell stage (V6-V8), to ensure sufficient potassium supply.

Split Applications: Avoid applying a large amount all at once. Splitting the application into a base fertilizer and one or more topdressings improves nutrient use efficiency.

Soil Monitoring: Regularly test soil pH and nutrient levels, and adjust the fertilization plan based on the actual conditions.

For corn growers in the international market, the rational use of 15-15-6 compound fertilizer can not only increase yield and quality but also help meet increasingly stringent environmental standards. The key is balanced fertilization, combined with organic amendments, to achieve a win-win situation for high corn yields and soil health.

From Field Need to Factory Granule: The Science of NPK Fertilizer

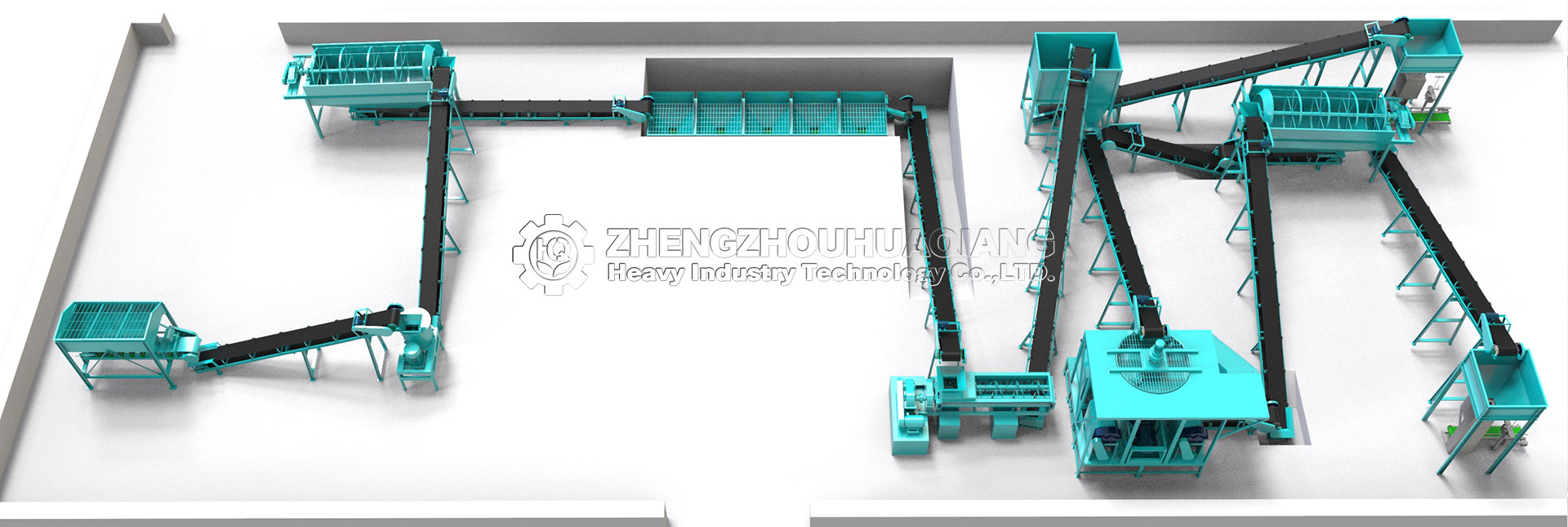

The scientific application of specialized NPK formulas like 15-15-6 begins with precision manufacturing. The npk fertilizer manufacturing process is designed to produce consistent, high-quality granules. It starts with accurate formulation using a npk blending machine or a bulk blending fertilizer machine to ensure the precise 15:15:6 ratio. This careful blending is a critical first step in the manufacturing of npk fertilizer to guarantee nutrient uniformity in every pellet.

The mixed materials are then transformed through advanced npk granulation machine technology. Equipment like the npk fertilizer granulator machine within a complete npk fertilizer production line converts the powder into durable, uniform granules. This process of fertilizer granulation is central to modern npk fertilizer production technology, ensuring that each granule delivers the intended nutrient profile reliably to the soil. The integration of these specialized npk fertilizer machine systems allows for the efficient production of tailored fertilizers that meet specific crop requirements, directly supporting the sustainable and high-yield agricultural practices discussed for crops like corn.