Overview Horizontal agitation and extrusion granulation technology is one of the core processes in the production of organic and bio-fertilizers. Through unique mechanical action, it directly transforms high-moisture, high-viscosity organic raw materials into uniform granules without external heating or the addition of binders. This low-temperature, low-energy granulation method is particularly suitable for processing organic waste such as livestock and poultry manure, straw, and mushroom residue, making it the preferred technology for modern organic fertilizer production.

Technical Principles and Process Characteristics

The core of this technology lies in the double-helix agitator shaft design within the horizontal main unit. When the motor drives the agitator shaft to rotate, the material undergoes three key processes within the cylinder: powerful agitation and mixing, axial propulsion and conveying, and radial extrusion molding. The raw material is first thoroughly kneaded and mixed by the propeller blades to form a uniform material agglomerate; then, under axial thrust, it moves towards the discharge end; finally, it is extruded into cylindrical granules through the discharge screen.

The greatest advantage of this process is that it operates at low temperatures throughout. Unlike traditional granulation processes that require high-temperature drying, horizontal mixing granulation maintains a relatively constant material temperature, ensuring a survival rate of over 95% for active microorganisms in the bio-fertilizer. Simultaneously, this technology can directly process raw materials with a moisture content of 25%-45%, eliminating the energy-intensive drying process and significantly reducing production costs.

Capacity and Configuration: Horizontal mixing granulation production lines offer a wide range of capacity to meet the needs of different production scales. Small production lines can process 1-3 tons of material per hour, suitable for family farms or small organic fertilizer workshops; medium-sized production lines have a capacity of 3-8 tons/hour, meeting the needs of county-level fertilizer plants; large production lines can reach 8-15 tons/hour, suitable for large-scale production enterprises; customized high-capacity lines can even reach a capacity of 15-25 tons/hour.

Key factors affecting capacity include raw material characteristics, moisture content, and equipment parameters. Organic fertilizer compost typically has a lower capacity, while the capacity of compound fertilizer raw materials can be increased by 20%-30%. The optimal moisture content range is 30%-35%. Too high a moisture content will cause material adhesion, while too low a moisture content will affect the molding effect. Regarding equipment, proper adjustment of the stirring shaft speed and extrusion gap is crucial for optimizing production capacity.

Application Areas and Product Compatibility

This technology is mainly applicable to two categories of fertilizer production:

The primary categories include pure organic fertilizer, bio-organic fertilizer, and refined organic fertilizer. These products are based on organic materials such as livestock and poultry manure and agricultural waste, and can be directly produced into commercial organic fertilizer that meets national standards using this technology.

Compatible categories include organic-inorganic compound fertilizers, micronutrient fertilizers, and low-concentration compound fertilizers. These products require the addition of inorganic nutrients to the organic fertilizer base; efficient production can be achieved through minor process adjustments.

It should be noted that this technology is not suitable for high-concentration compound fertilizers, pure inorganic fertilizers, or other fertilizer types that require high-temperature drying or special coating treatment.

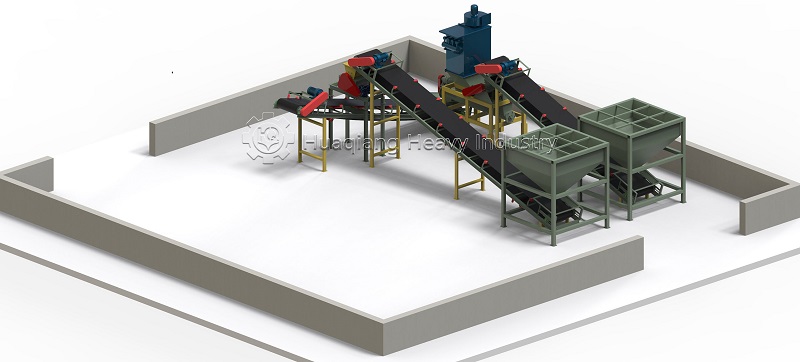

Production Line Composition and Process

A complete horizontal mixing granulation production line typically includes three main sections: pretreatment, granulation, and post-treatment.

Pretreatment equipment includes crushers and mixers to ensure the raw materials achieve suitable particle size and uniformity.

The granulation machine is the core equipment, completing the material forming process.

Post-treatment equipment includes screening machines, polishing machines, and cooling devices to improve the quality of the final product.

The production line can be flexibly configured according to investment budget and production needs. Basic configurations meet basic production requirements, while high-end configurations can further improve the product’s appearance quality and storage stability.

Technological Advantages and Industry Comparison

Compared to traditional granulation technologies, horizontal mixing extrusion granulation has multiple advantages:

In terms of energy consumption, the energy consumption per ton of fertilizer is only 20-30 kWh, one-fifth of that of rotary drum granulation.

In terms of raw material adaptability, it can directly process organic materials with high moisture content without pre-drying.

In trms of bioactivity protection, the low-temperature process ensures a high survival rate of effective bacteria in the microbial fertilizer.

In terms of operating costs, the equipment has a simple structure, is easy to maintain, and has a long service life. Compared to flat die granulation, this technology has less stringent requirements on raw material moisture content; compared to rotary drum granulation, it has lower investment and operating costs. These advantages give it a significant competitive edge in the organic fertilizer production sector.

Selection and Operation Recommendations

Choosing a suitable production line requires consideration of capacity requirements, product positioning, and raw material characteristics. For production enterprises primarily producing bio-organic fertilizers, horizontal mixing granulation is an ideal choice. Equipment configuration should prioritize the performance of core equipment, followed by the addition of auxiliary equipment based on actual needs.

In production and operation, raw material quality control is crucial. Maturity, moisture content, and particle size distribution directly affect production efficiency and product quality. Regarding equipment operation, the mixing speed needs to be adjusted according to the type of raw material, and the condition of vulnerable parts should be checked regularly.

Finished product quality control should focus on key indicators such as particle strength, moisture content, and granulation rate to ensure that the product meets national standards. Simultaneously, environmental requirements cannot be ignored, necessitating the installation of appropriate dust removal and deodorization equipment.

Development Trends

In the future, horizontal mixing granulation technology will develop towards intelligence, integration, and multi-functionality. By adding an automated control system, production parameters can be precisely adjusted; by integrating and optimizing equipment, overall production efficiency can be improved; and by innovating processes, the technology can be expanded to the resource utilization of more organic solid wastes such as kitchen waste and municipal sludge. These developments will further enhance the technology’s market competitiveness and environmental benefits, contributing to global sustainable agriculture.

Conclusion: An Integrated System for Sustainable Fertilizer Production

In conclusion, horizontal agitation and extrusion granulation stands as a cornerstone technology for efficient, low-energy organic fertilizer manufacturing. Its ability to process high-moisture organic waste into quality granules without damaging microbial life makes it indispensable for modern organic fertilizer production line operations focused on bio organic fertilizer production line outputs.

This granulation method is a key component within the broader ecosystem of organic fertilizer granulation technology. A complete system begins with high-quality raw material produced through controlled organic fertilizer fermentation, optimized by fermentation composting turning technology. The resulting mature compost is then shaped using the horizontal extrusion granulator, which can be complemented by other granulation technologies like a flat die pelleting machine or innovative designs such as the new type organic fertilizer granulator and new type two in one organic fertilizer granulator for specific product requirements. Together, these technologies form a versatile and efficient production chain.

Ultimately, by offering a perfect balance of energy efficiency, product quality, and raw material adaptability, this technology is a powerful driver for the sustainable conversion of organic waste into valuable soil resources, supporting the growth of circular and regenerative agriculture worldwide.