As an important support for sustainable agriculture, the quality control and scientific application of organic fertilizer directly affect agricultural production efficiency and ecological environment safety. With the implementation of the national standard NY525-2021 “Organic Fertilizers”, organic fertilizer production and application have entered a new phase of standardization and scientific management.

National Standards: Foundation of Quality Assurance

The current national standards establish clear quantitative indicators for organic fertilizer quality. Organic matter content must not be less than 45%, total nutrients (nitrogen, phosphorus, potassium) must reach above 5%, and moisture content must be controlled within 30%. These technical indicators ensure the nutritional value and application effectiveness of organic fertilizer. Simultaneously, strict limits on heavy metal content, ascaris egg mortality rate, and fecal coliform counts ensure environmental safety and hygiene standards of organic fertilizer.

Quality control runs through the entire production process. Starting from raw material testing, heavy metal-contaminated materials are excluded from the production line. During fermentation, temperature, moisture content, and pH values need monitoring to ensure thorough decomposition. Before leaving the factory, every batch of finished products requires comprehensive testing, with unqualified products strictly prohibited from entering the market. Proper storage conditions are equally important, as dry and ventilated environments effectively maintain fertilizer efficacy.

Scientific Application: Key to Maximizing Benefits

Organic fertilizer application needs adjustment according to different crops and soil conditions. For field crops like wheat and corn, base fertilizer application of 200-500 kilograms per mu combined with deep plowing yields good results. Economic crops like vegetables and fruits require higher application rates, typically 500-1000 kilograms per mu, with best results achieved when applied 15-20 days before planting.

The application of topdressing techniques is also important. Timely supplementation of organic fertilizer during crop growth periods can continuously supply nutrients. Foliar spraying of humic acid solutions is an effective method for rapidly supplementing organic nutrition. Scientific combination of organic and chemical fertilizers can both meet immediate crop nutrient needs and improve long-term soil fertility, avoiding soil degradation caused by exclusive chemical fertilizer use.

Precautions and Optimization Strategies

Applying undecomposed organic fertilizer can cause root burning and ammonia toxicity, so complete decomposition must be ensured. Different crops have significantly varying nutrient requirements – fertilizer-loving crops like watermelons and strawberries can appropriately increase application rates, while crops like lettuce and spinach need controlled application.

Soil condition considerations are equally important. Long-term organic fertilizer application in acidic soils may exacerbate acidification, requiring lime supplementation to adjust pH. Alkaline soils are suitable for humic acid-type organic fertilizers, helping improve soil structure. For saline-alkali and compacted soils, continuous organic fertilizer application for 2-3 years can significantly improve soil environment.

Technological Development Trends

The organic fertilizer industry is developing toward intelligence and functionality. Internet of Things technology applications make production processes more precise and controllable, while automated equipment improves production efficiency and product quality stability. Specialized organic fertilizers meet specific needs of different crops, and organic fertilizers with added functional microorganisms demonstrate better disease resistance and growth promotion effects.

Comprehensive resource utilization is becoming a new development direction. Using various organic wastes to produce organic fertilizer, combined with technologies like biogas power generation, achieves multi-level resource utilization. Improvement of green organic certification systems provides reliable guarantees for high-end agricultural product production, enhancing the added value and market competitiveness of organic fertilizers.

Organic Fertilizer Development from a Global Perspective

In the context of global agricultural sustainable development, the importance of organic fertilizer is becoming increasingly prominent. It not only provides nutrients needed for crop growth but, more importantly, improves soil ecosystems and promotes long-term healthy agricultural development. With technological advancements and standard improvements, organic fertilizer will play an increasingly important role in global agriculture.

Through scientific quality control systems, reasonable application techniques, and continuous innovation and research, organic fertilizer is becoming a key link connecting agricultural production, environmental protection, and resource recycling, making significant contributions to building more sustainable agricultural systems.

Integrated Fertilizer Production Systems for Modern Agriculture

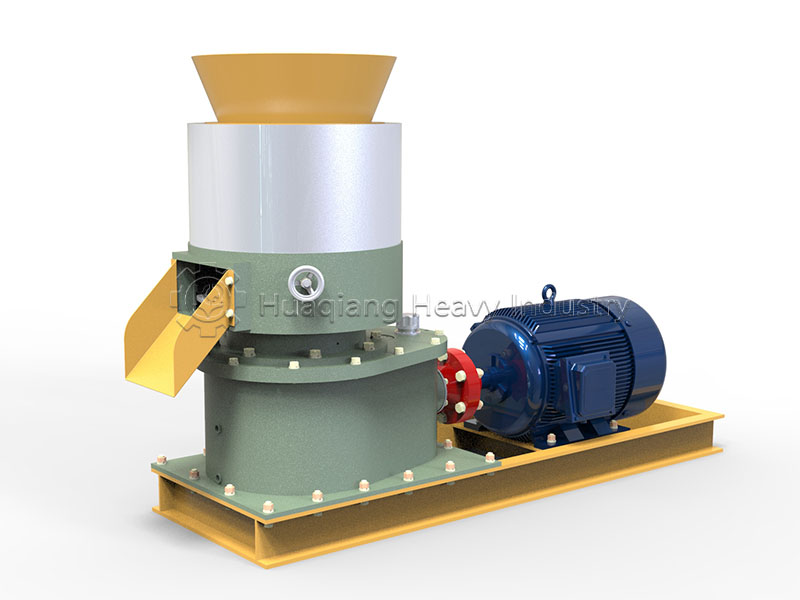

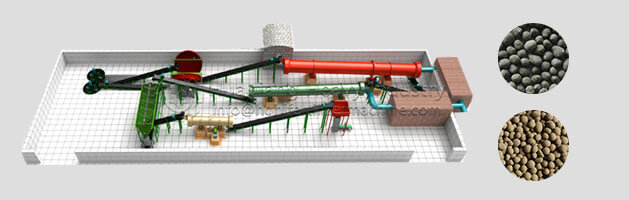

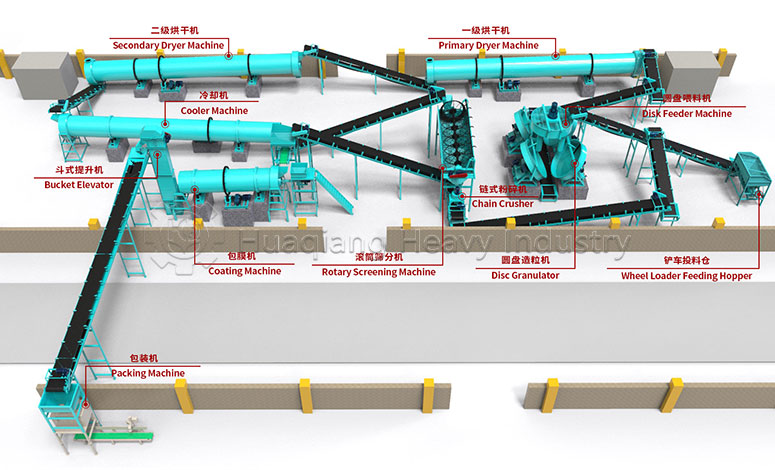

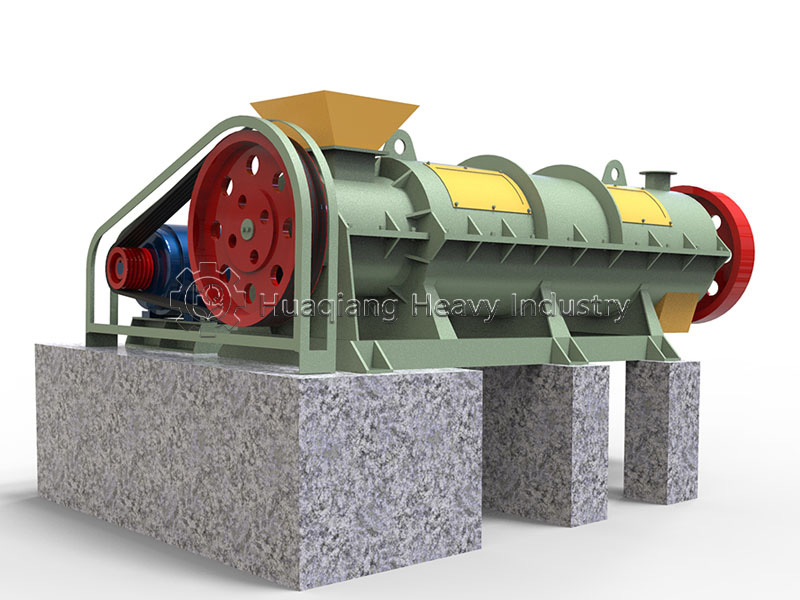

High-quality fertilizer production, whether organic or compound, relies on sophisticated industrial systems. The organic fertilizer production line often begins with biological processing using equipment like the windrow composting machine, followed by shaping in a disc granulator for shaping uniform pellets. Similarly, the complete npk fertilizer production line integrates precision equipment such as the npk blending machine with various fertilizer granulation processes to produce consistent compound fertilizers.

Granulation technology is central to both production streams. The disc granulator machine is a core component of many disc granulation production line setups, creating spherical granules. For specialized applications, alternative technologies are employed, such as the double roller press granulator in a roller press granulator production line for dry compaction. These diverse fertilizer granulator systems, whether within a bio organic fertilizer production line or a standard NPK line, ensure that final products meet stringent quality standards for effective and sustainable field application, supporting the scientific principles of soil health and crop nutrition.