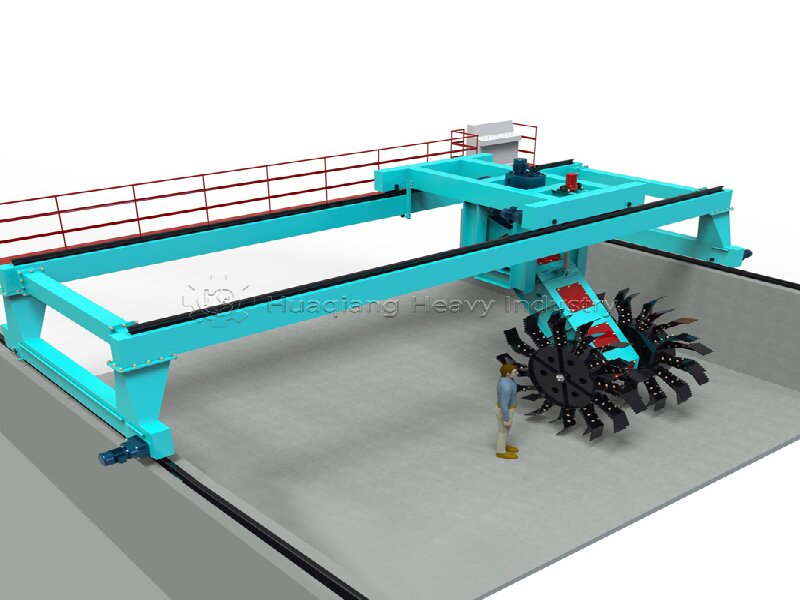

A Powerful Tool for Large-Scale Composting Operations: Crawler-Type Compost Turning Machine

In the field of large-scale organic fertilizer production, the efficiency and stability of the composting fermentation process directly determine the production capacity and profitability of enterprises. Faced with large fermentation sites, diverse organic materials, and complex terrain conditions, traditional turning equipment often struggles to meet the demands of efficient operation. The emergence of the crawler-type compost turning machine, with its unique crawler design and powerful operating performance, has become a core supporting equipment for large-scale composting projects, providing an efficient solution for the resource utilization of large-scale organic waste.

As a heavy-duty self-propelled machine, the most distinctive feature of the crawler-type compost turning machine is its use of rubber tracks as the walking mechanism. This design gives it excellent stability and mobility in soft, rugged fermentation sites. Compared to traditional wheeled equipment, which is prone to slipping and sinking, rubber tracks increase the contact area with the ground, effectively distributing the equipment’s weight. This allows for easy adaptation to uneven terrain and flexible movement in muddy fermentation areas, completely breaking down the limitations of site conditions on composting operations and providing a fundamental guarantee for large-scale windrow composting. Its core function lies in accelerating the maturation of organic materials through three main actions: turning, crushing, and aeration, transforming organic waste such as livestock manure, crop straw, and biochar into high-quality organic fertilizer.

The tracked compost turner has a clear and efficient workflow, achieving full-process adaptation from material pretreatment to fermentation acceleration. The first step is the windrow forming stage, where operators must organize the collected organic waste into long, strip-shaped piles, laying the foundation for subsequent turning operations. Subsequently, the equipment enters the core crawling and turning stage. Operators control the equipment from the cab using simple control devices such as levers, guiding it along the windrows. Simultaneously, the hydraulically driven mixing drum rotates at high speed, its agitating teeth penetrating deep into the pile to lift, thoroughly mix, and disperse the material at the bottom. This process not only turns the material but also achieves two key objectives: first, aeration and oxygenation, providing sufficient oxygen for the aerobic decomposition process, a core requirement for microbial growth and metabolism, directly determining fermentation efficiency; second, breaking up clumps, as the agitating teeth effectively break up hardened clumps in the material, ensuring more uniform mixing and preventing incomplete fermentation or overheating in certain areas, thus guaranteeing stable fermentation quality. The entire operation requires no manual assistance, allowing a single operator to manage large composting sites, significantly improving the operational efficiency of large-scale composting projects.

In large-scale composting operations, the core features and application advantages of tracked compost turners are particularly prominent. High capacity is one of its core competitive advantages. This equipment can process 500-1500 cubic meters or even more organic waste per hour, easily matching the large-scale production needs of industrial composting plants and large farms, significantly shortening the overall fermentation cycle. Stability and adaptability further amplify its application value. The rubber track design allows the equipment to operate stably in various complex terrains, while its wide adaptability to materials allows it to process various organic wastes such as livestock manure, agricultural straw, and biochar, reducing application limitations. In terms of practical application benefits, this equipment not only accelerates the conversion of organic waste into nutrient-rich compost and improves production efficiency, but also improves compost quality through uniform turning, resulting in more uniform organic fertilizer with more balanced nutrients. At the same time, the simple operation reduces labor costs, and the self-propelled design reduces auxiliary operation time, comprehensively reducing costs and increasing efficiency for enterprises.

With the rapid development of organic agriculture and the environmental protection industry, the demand for large-scale organic waste treatment is increasing daily. Tracked compost turners, with their core advantages of high capacity, strong stability, and wide adaptability, as well as their application value in improving efficiency, enhancing quality, and reducing costs, have become indispensable key equipment for large-scale composting projects. They not only promote the industrial upgrading of organic fertilizer production but also help achieve the harmless treatment and resource utilization of organic waste, providing solid technical equipment support for the development of ecological circular agriculture.

A Keystone in Modern Biofertilizer Manufacturing

The crawler-type compost turning machine is a foundational component of industrial-scale fermentation composting technology for organic fertilizer. As a highly efficient self propelled compost production machine, it is specifically engineered to accelerate the organic fertilizer fermentation process for windrow systems, providing the essential aeration and mixing that drive microbial decomposition.

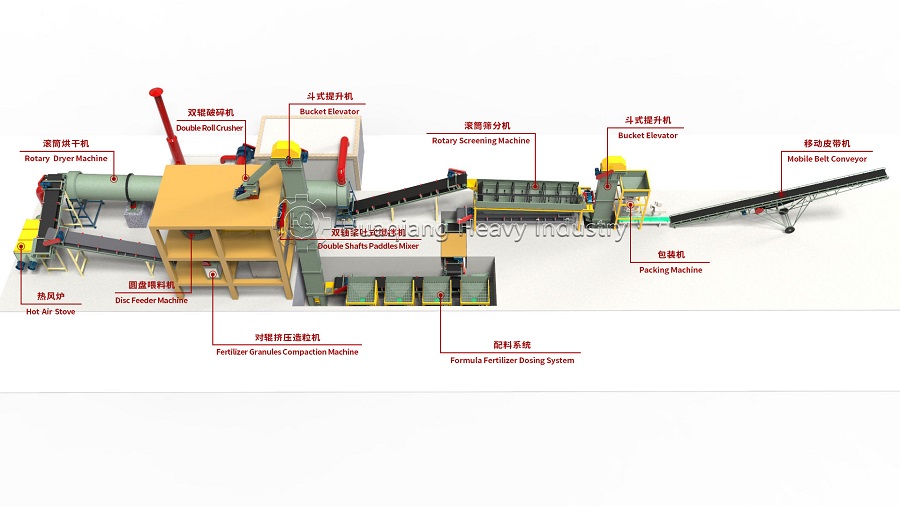

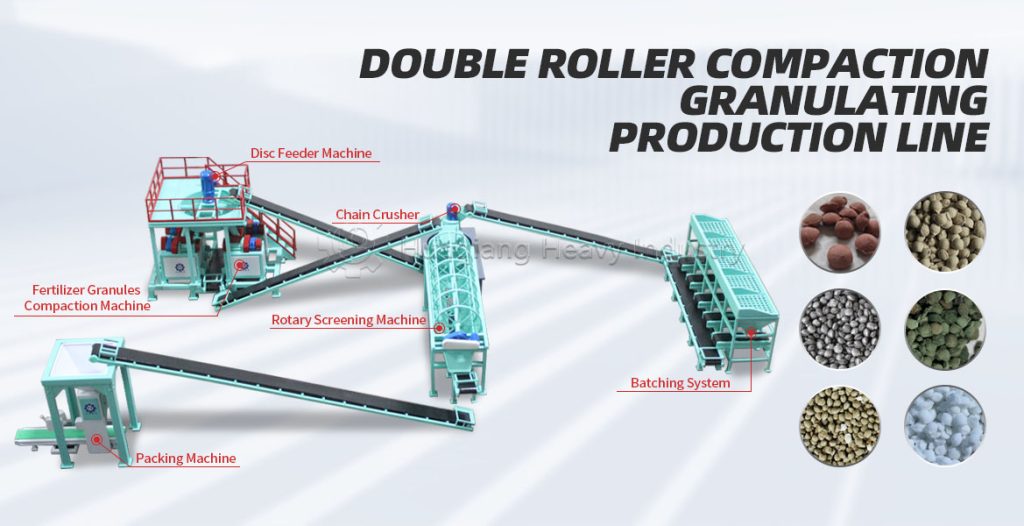

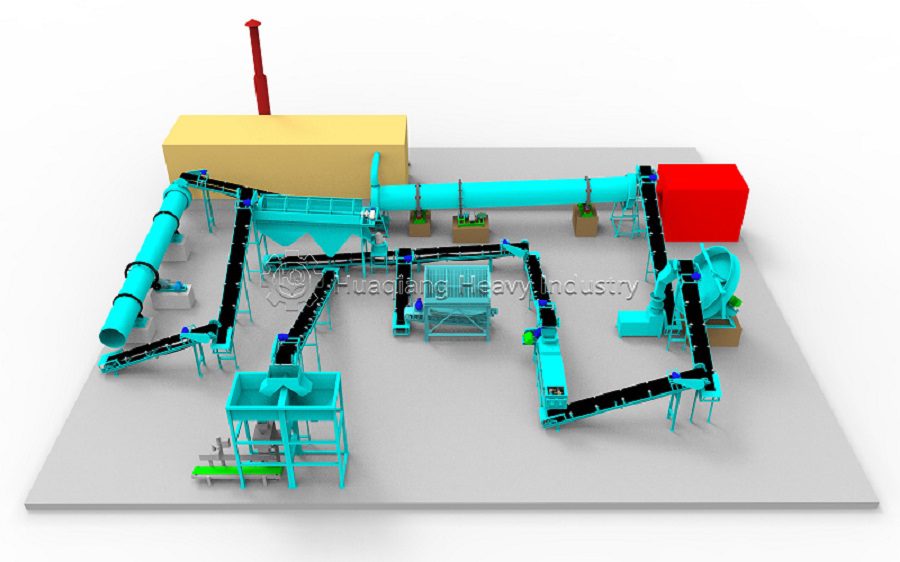

This machine is part of a diverse family of solutions within the broader fermentation composting turning technology sector. Depending on the scale and layout of the operation, producers might choose alternative equipment such as a high-capacity large wheel compost turning machine for wide rows, a precise double screws compost turning machine for controlled mixing, or implement a trough-type aerobic fermentation composting technology system for enclosed environments. Each serves the same vital function: transforming raw organic matter into stable, mature compost. This high-quality compost is the primary raw material for the subsequent equipments required for biofertilizer production, which further process it into commercial-grade organic or bio-organic fertilizers.

Thus, the tracked turner is not a standalone solution but a critical first-stage processing unit that enables the efficient, large-scale creation of the organic base upon which the entire biofertilizer industry depends.

.jpg)