Fertilizer Compactor: The Efficient and Energy-Saving Dry Granulation Technology

In modern agricultural production, the physical form of fertilizer is crucial for its storage, transportation, and application efficiency. Powdered fertilizers are prone to dust, caking, and uneven spreading, while traditional wet granulation processes are energy-intensive and complex. The fertilizer compactor, particularly the double-roller dry granulator, offers an efficient, energy-saving, and environmentally friendly solution for fertilizer processing through its unique room-temperature, high-pressure forming technology.

Core Principle: High-Pressure Forming Without Drying

The essence of the fertilizer compactor lies in its dry granulation process. This process completely eliminates the need for liquid binders and subsequent drying steps required in traditional wet granulation, achieving significant energy savings at the source. Its working principle is clear and efficient:

Uniform Feeding: Pre-mixed powdered fertilizer raw materials are continuously and evenly fed into the gap between two parallel rollers by a precise feeding system.

High-Pressure Compaction: The two rollers, driven by powerful hydraulic or mechanical force, rotate towards each other, exerting extreme pressure (tens to hundreds of Megapascals) on the material passing through the nip. In this instant, air between powder particles is forcibly expelled. Particles undergo plastic deformation and intermolecular bonding under immense mechanical force, being compressed into dense flakes or strips.

Crushing and Screening: The extruded continuous flakes are then sent to a crusher and broken into fragments of various sizes. These fragments are graded by multi-layer vibrating screens to select finished granules within the target size range (typically 2-5 mm). Oversized fragments are re-crushed, and fine powder is recycled back into the process, ensuring zero raw material waste.

Optional Coating: To enhance the product’s anti-caking and controlled-release properties, the formed granules can undergo surface coating in a subsequent stage.

Remarkable Advantages: Energy Saving, Quality Improvement, Environmental Friendliness

Thanks to its unique working principle, the fertilizer compactor demonstrates multiple outstanding advantages:

Prominent Energy Saving and Consumption Reduction: By eliminating the drying step in the granulation process, its energy consumption is typically only 30%-50% of that of traditional wet processes, directly and significantly reducing production costs and carbon emissions.

Excellent Product Quality: The produced granules feature high density, great mechanical strength, and extremely low dust content. They possess good compressive and wear resistance, minimizing breakage or caking during long-distance transportation and storage. The uniform particle size ensures good flowability, facilitating precise mechanical application.

Wide Raw Material Adaptability: This technology is highly versatile for various fertilizer raw materials. Whether it’s NPK compound fertilizer, potassium chloride, ammonium sulfate, potassium sulfate, or various blended fertilizers, all can be processed effectively, and the requirements for raw material moisture content are relatively lenient.

Green and Environmentally Friendly: The entire production process occurs at room temperature without involving chemical reactions, generating no wastewater, exhaust gas, or harmful waste residue. It fully complies with the requirements of clean production and the circular economy.

Application and Prospects

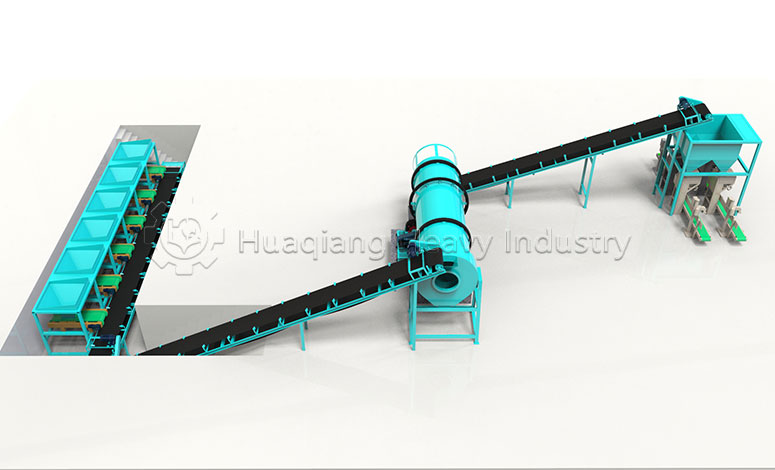

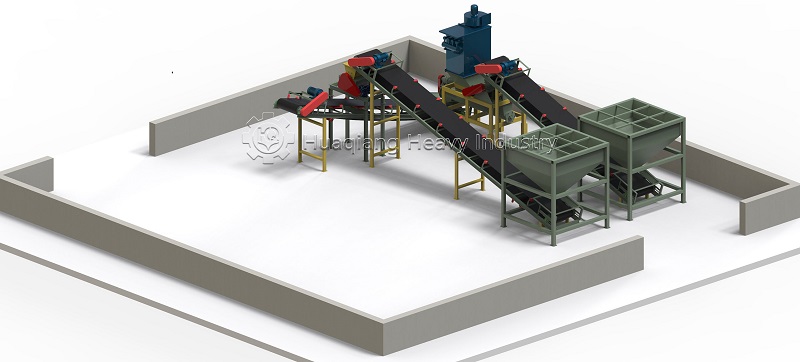

Currently, roller-type fertilizer compactors have become key equipment for upgrading and retrofitting in industries such as compound fertilizers, potash fertilizers, and micronutrient fertilizers. They are not only suitable for large-scale continuous production but their medium and small-scale designs also meet the market demand for customized formula fertilizers and small-batch production.

As global requirements for agricultural sustainability and industrial energy efficiency continue to increase, dry compaction granulation technology is gaining more attention due to its comprehensive advantages in energy saving, environmental protection, and product quality. In the future, through further integration with intelligent control systems, precision feeding technology, and more efficient roller surface design, fertilizer compactors will continue to propel the fertilizer processing industry towards greater efficiency, sustainability, and cost-effectiveness.

Conclusion: The Strategic Advantage of Dry Compaction Technology

In summary, the fertilizer compaction machine, specifically the double-roller dry granulator, establishes a new standard for efficient and sustainable fertilizer processing. By enabling fertilizer granules compaction at room temperature, it eliminates the need for energy-intensive drying, offering a clear path to lower costs and a reduced carbon footprint.

This dry fertilizer compaction process is a vital part of the modern suite of fertilizer granulation processes. It serves as a key fertilizer processing machine within an integrated npk manufacturing process. While traditional methods like drum granulation using a rotary drum granulator remain important for some applications, the roller press granulator production line offers a compelling dry alternative. Its role is complementary to other technologies like a disc granulation production line used in organic fertilizer manufacturing process, providing manufacturers with the flexibility to choose the optimal npk fertilizer production technology based on raw materials and product specifications.

Ultimately, with its unmatched energy efficiency, product quality, and environmental benefits, the fertilizer compactor is poised to play an increasingly central role in the future of sustainable fertilizer manufacturing worldwide.