In sub-Saharan Africa, particularly in Ethiopia, farmers face a severe long-term challenge: their land is becoming increasingly “thin.” Soil acidification, nutrient depletion, and declining organic matter content act like invisible shackles, constraining crop yields and affecting the food security of millions. Chemical fertilizers once offered hope for boosting production, but their high cost, unstable supply, and long-term detrimental effects on soil structure and the environment have exposed their limitations. So, where is the way forward?

Mounting evidence points to an ancient yet renewed answer: organic fertilizers. By transforming agricultural waste into a valuable resource, Ethiopian farmers are exploring a path to restore soil health and achieve sustainable agriculture.

Soil “Hunger” and the Loss of Organic Matter

The Ethiopian Highlands, known as Africa’s “water tower,” are facing a soil crisis. Continuous cultivation, soil erosion, and overgrazing are rapidly depleting the soil’s organic matter and essential nutrients. Soil organic carbon is the core of soil fertility, acting like the soil’s “savings account” for nutrients and water. However, under tropical conditions, organic matter decomposes quickly, and this “account” is being severely overdrawn.

The traditional solution—chemical fertilizers—can quickly replenish elements like nitrogen and phosphorus, but it’s akin to giving the soil only a “stimulant.” It fails to address the fundamental issues of damaged soil structure and organic matter deficiency. It is expensive and does not provide the “food” needed by soil microbes. In the long run, soil health continues to deteriorate.

The Treasure at Hand: Overlooked Agricultural Waste

Surprisingly, the resources to solve the problem are right around the farmers. Crop residues, livestock manure, processing waste… These materials, often seen as “trash,” are actually rich in organic matter and various nutrients. Ethiopia’s diverse agro-ecological zones, from the humid highlands to the arid lowlands, all generate substantial amounts of such organic resources. In the past, these resources were either discarded or burned openly, their value left untapped.

Now, there is a growing recognition that scientifically processing this waste can transform it into “black gold” that nourishes the soil. This not only reduces environmental pollution but also saves farmers money on fertilizer purchases, creating a low-cost, sustainable model of circular agriculture.

Turning Waste into Wonder: Three Key Transformation Technologies

Transforming agricultural waste into effective organic fertilizers primarily involves three popular and smallholder-friendly technologies:

Composting: This is the most traditional and widely used method. Manure, straw, weeds, and other materials are layered in piles. Over several months, through the action of microorganisms, they decompose into a stable, mature, and odorless dark brown substance—compost. Compost improves soil structure and releases nutrients slowly, but the production cycle is long, and nutrients (especially nitrogen) can be lost if not managed properly.

Vermicomposting: This is a more efficient and “smarter” method. It uses earthworms (particularly species like Eisenia fetida) to digest organic waste. The excreted castings of the worms, known as “vermicompost,” are a fine, granular fertilizer. Rich in beneficial microbes and plant growth hormones, vermicompost has higher nutrient content and is more readily available to plants, earning it the title “king of organic fertilizers.” It significantly enhances soil biological activity.

Biogas Digestion: This is a “two-birds-one-stone” process. Manure and other organic materials are anaerobically fermented in a sealed biogas digester. This produces clean biogas for cooking and lighting, while the byproduct—bioslurry—is a high-quality liquid organic fertilizer. Bioslurry has comprehensive nutrients, is fast-acting, and can even help with disease and pest control. The government is actively promoting household biogas digesters to address both energy and fertilizer needs simultaneously.

Visible Benefits: Nourishing Land, Boosting Yields

Research shows that using these organic fertilizers brings tangible benefits to soil and crops:

Soil Improvement: They act like soil “prebiotics” and “binders,” increasing soil organic matter, loosening compacted soil for better aeration, and enhancing water and nutrient retention.

Balanced Nutrition: Organic fertilizers contain not only nitrogen, phosphorus, and potassium but also calcium, magnesium, sulfur, and various trace elements, providing a more comprehensive diet for crops and avoiding the nutrient imbalances caused by single-chemical fertilizers.

Activating Life: They provide abundant food for beneficial soil organisms like microbes and earthworms, helping to establish a healthy, vibrant soil ecosystem—the foundation for long-term fertility.

Increased Yield and Resilience: Numerous field trials confirm that the judicious application of organic fertilizers, or their combined use with small amounts of chemical fertilizers, can steadily increase the yields of staple crops like maize, wheat, and teff. More importantly, healthy soil allows crops to better withstand climatic shocks like drought.

Challenges and the Future

Of course, promoting organic fertilizers is not without challenges. Farmers need to master proper production and application techniques. Organic fertilizers are bulky, requiring more labor for transport and application. Their nutrient release is slower, necessitating better alignment with farming schedules.

However, faced with the dual pressures of volatile fertilizer prices and soil degradation, investing in the valorization of organic waste is undoubtedly a wise choice for Ethiopian agriculture to move towards sustainability. It is not just a technical issue but a shift in mindset: from relying on external inputs to tapping into and recycling resources within the farming system itself.

By turning “waste” into “wealth,” Ethiopian farmers are using their wisdom to awaken the sleeping land, writing a hopeful chapter for food security and ecological restoration. This path proves that the most effective solutions are often embedded within the natural cycles of farming tradition itself.

Scaling Up Organic Fertilizer Production for Sustainable Agriculture

The on-farm practices of composting, vermicomposting, and biogas digestion in Ethiopia demonstrate the foundational principles of organic fertilizer manufacturing. These decentralized methods of organic fertilizer fermentation can be scaled up through more systematic approaches. Modern fermentation composting turning technology, utilizing equipment like the chain compost turning machine for smaller operations or the large wheel compost turning machine for larger windrows, significantly improves the efficiency and consistency of the decomposition process.

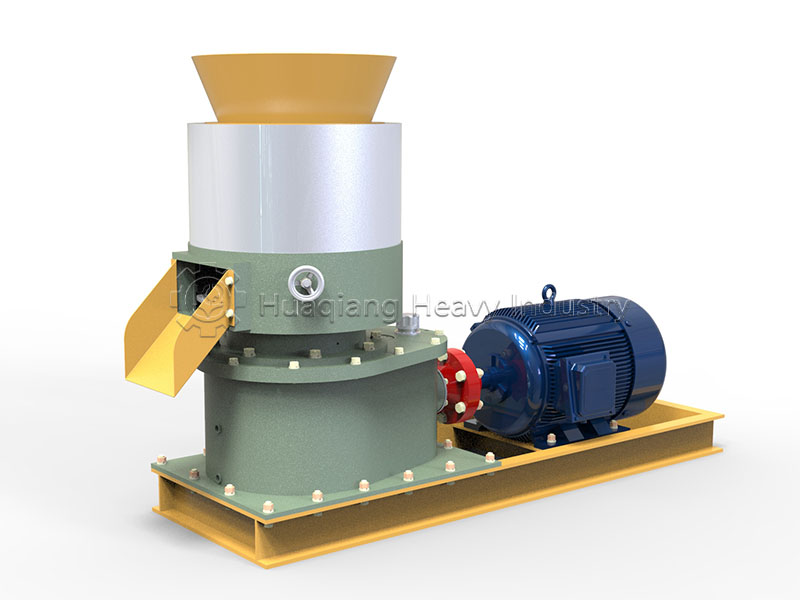

To transform locally produced compost into a standardized, marketable product, the material can be integrated into a formal organic fertilizer production line. This line would include an organic fertilizer granulator—such as a new type two in one organic fertilizer granulator that combines mixing and shaping—to create uniform pellets. For enhanced biological value, this process can be part of a bio organic fertilizer production line, inoculating the compost with beneficial microbes before granulation. This hybrid model, connecting localized waste collection and initial processing with centralized, efficient manufacturing, offers a scalable pathway to produce high-quality organic fertilizers that can restore soil health, boost yields, and build agricultural resilience across Ethiopia and similar regions.