Large Wheel Compost Turner: Core of Large-scale Organic Fertilizer Production

In the field of large-scale organic fertilizer production, the large wheel compost turning machine is becoming a key equipment for ten-thousand-ton production lines. This heavy-duty turning equipment provides efficient solutions for resource utilization of large-scale organic waste through innovative design concepts and powerful processing capabilities, promoting the development of the organic fertilizer industry toward scale and intelligence.

Revolutionary Design Principle

The core design of the large wheel compost turning machine lies in its oversized disc structure, typically reaching 5-10 meters in diameter. This design enables the equipment to cover 5-8 meter wide windrows in a single pass, greatly improving operational efficiency. The turning teeth installed on the disc edge utilize centrifugal force during rotation to lift materials from the bottom upward and disperse them outward, creating comprehensive mixing effects.

Compared to traditional turning equipment, the large disc design’s advantages lie in its extensive coverage range and powerful turning capability. Under centrifugal force, the contact area between materials and air increases by 3-5 times, significantly improving oxygen supply efficiency and creating ideal conditions for active metabolism of aerobic microorganisms. This perfect combination of physical effects and biological processes significantly enhances fermentation efficiency.

Exceptional Large-scale Processing Capacity

The most prominent feature of the large wheel compost turning machine is its astonishing processing capacity. A single unit can process 500-1000 tons of organic material daily, 5-10 times that of traditional equipment. This capability makes it particularly suitable for large-scale production scenarios such as large livestock farms, municipal sludge treatment plants, and industrial organic waste processing centers.

The equipment demonstrates good adaptability to various organic raw materials, including livestock manure, crop straw, industrial organic waste, and municipal sludge. Through scientific pretreatment and parameter adjustment, materials with different characteristics can achieve ideal fermentation effects in this equipment. This flexibility is an indispensable characteristic in large-scale organic waste treatment.

Intelligent Operation Control

Modern large wheel compost turning machines are equipped with advanced electronic control systems, achieving intelligent and convenient operation. Through touchscreen interfaces, operators can monitor various operational parameters in real-time, including disc rotation speed, travel speed, material temperature, and humidity. Sensor systems can automatically detect equipment status and fermentation progress, promptly alerting and taking protective measures when abnormalities occur.

Increased automation significantly reduces operational difficulty and labor requirements. Traditional organic fertilizer fermentation required substantial manual involvement in turning operations, while large wheel compost turning machines require only 1-2 operators to complete fermentation management for large-scale production lines. This efficiency improvement not only reduces production costs but also enhances operational safety and consistency.

Optimized Fermentation Process

The application of large wheel compost turning machines requires coordination with scientific fermentation processes. From raw material pretreatment to windrow stacking, then to phased turning fermentation, each stage requires careful design and strict control. The equipment can automatically adjust working parameters according to different fermentation stages, ensuring efficient progress throughout the fermentation process.

During fermentation, material temperature can be stably maintained within the ideal range of 60-70°C. This temperature not only accelerates organic matter decomposition but also effectively eliminates pathogenic microorganisms and weed seeds. After 20-30 days of scientific management, raw materials can be transformed into high-quality organic fertilizer, achieving complete resource utilization of waste.

Maintenance and Sustainable Development

To ensure long-term stable equipment operation, scientific maintenance is crucial. Regular lubrication, wear inspection, and cleaning work can extend equipment service life and reduce failure rates. Wear parts like turning teeth adopt modular designs and can be individually replaced after wear, significantly reducing maintenance costs.

In today’s global consensus on sustainable development, large wheel compost turning machines not only solve the treatment challenges of large-scale organic waste but also provide high-quality organic fertilizer for agricultural production. This recycling model reduces environmental pollution, improves soil quality, and promotes sustainable agricultural development. With continuous technological advancement, this equipment will continue to play important roles in organic fertilizer production and environmental protection.

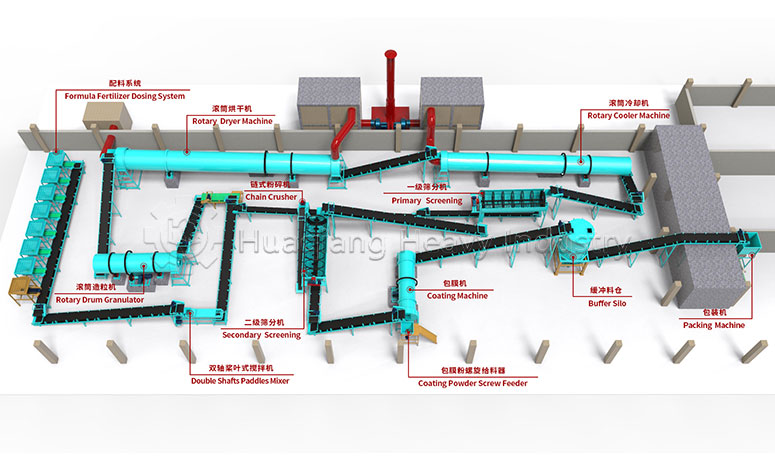

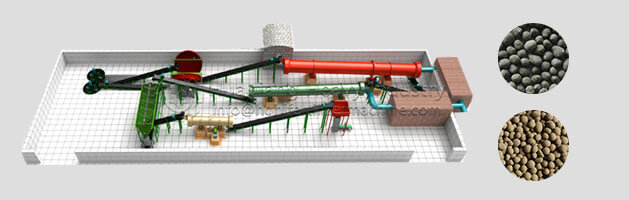

Integrated Systems for Modern Organic Fertilizer Manufacturing

The large wheel compost turner is a cornerstone of efficient fermentation composting technology for organic fertilizer. This specialized fermentation composting turning technology, particularly within trough-type aerobic fermentation composting technology systems, optimizes the organic fertilizer fermentation process. Often used alongside other essential pre-composting processing equipment, such as a multiple silos single weigh static batching system for precise raw material formulation, it forms part of the core equipments required for biofertilizer production. The combination of precise batching and efficient turning creates the ideal conditions for rapid and uniform biodegradation.

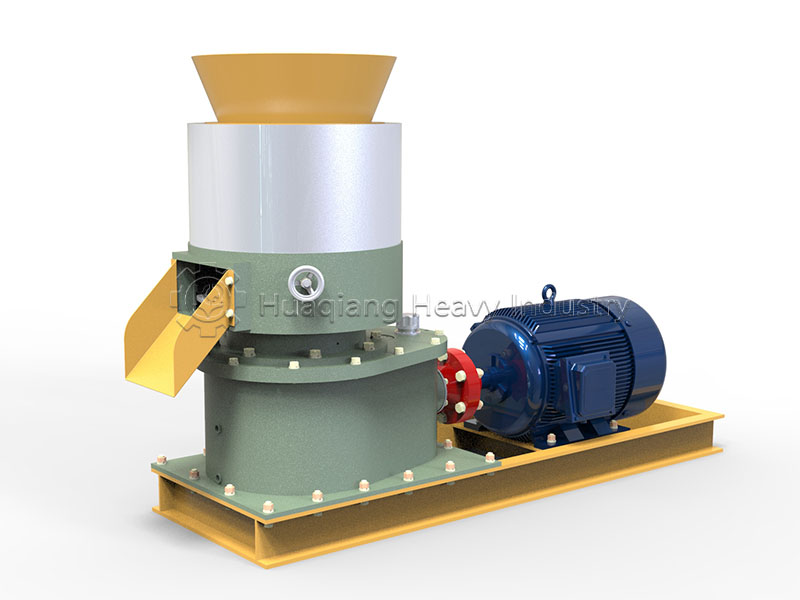

Following complete fermentation, the matured organic matter proceeds to granulation. A disc granulator for shaping is commonly used in the subsequent processing line to transform the compost into uniform, market-ready pellets. This integrated approach—from initial weighing and mixing through optimized fermentation to final shaping—demonstrates the sophistication of modern organic fertilizer manufacturing. It enables the efficient, large-scale conversion of diverse organic waste streams into valuable, high-quality biofertilizers, closing nutrient loops, improving soil health, and supporting sustainable agricultural systems on a global scale.