Chain Compost Turner: The Efficient Engine for Large-Scale Composting

Innovative chain drive design delivers powerful performance and reliability for large composting facilities

The Unique Advantages of Chain Technology

In modern large-scale composting facilities and organic fertilizer production factories, the chain compost turning machine has become the preferred compost fertilizer machine for processing organic waste, thanks to its outstanding performance and reliable chain drive systems. As one of the essential equipments required for biofertilizer production, these specialized machines efficiently handle various organic materials including livestock manure and crop straw, accelerating the decomposition process crucial for bio organic fertilizer production.

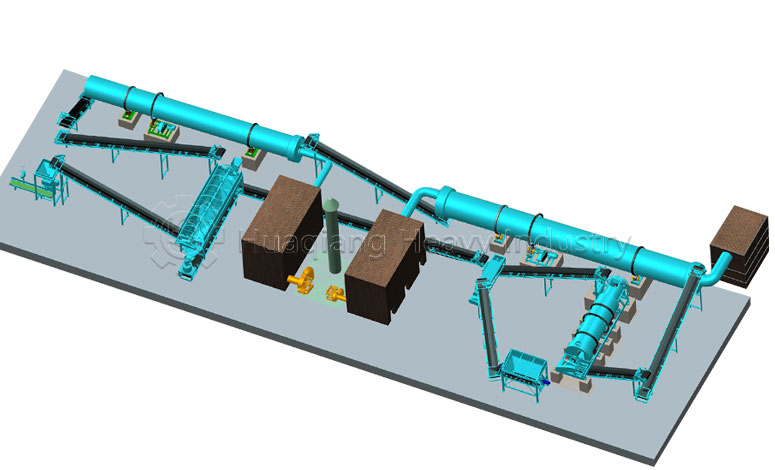

This robust fertilizer production machine serves as the foundational equipment that seamlessly integrates with downstream granulation systems. The processed compost material can be efficiently channeled into various production lines, including the comprehensive NPK fertilizer production line or specialized organic fertilizer setups featuring disc granulation production line technology. For operations requiring different granulation methods, the system accommodates both rotary granulator and drum granulation equipment, while the double roller press granulator provides an alternative compaction-based approach for specific material types.

The versatility of the chain compost turning machine within the broader context of equipments required for biofertilizer production makes it an invaluable asset for modern fertilizer manufacturers. Whether supporting standalone bio organic fertilizer production or complementing more complex integrated systems, this equipment demonstrates remarkable adaptability across different production methodologies and end-product requirements.

The core appeal of chain compost turners lies in their unique chain turning mechanism. When the motor drives the sprocket to operate, the chain drives turning blades deep into the material pile, working like countless dexterous arms within the material. This design not only ensures turning depth and uniformity but also effectively increases oxygen supply, creating an ideal growth environment for microorganisms and significantly improving fermentation efficiency.

Precision Engineering: Perfect Integration of Professional Systems

The exceptional performance of chain compost turners stems from the precise coordination of six professional systems. Each system is carefully designed and optimized, collectively forming the core competitiveness of this efficient composting equipment.

Chain Turning Mechanism

Composed of sprockets, chains, and turning blades, motor-driven sprockets propel blades deep into material piles for efficient turning and mixing

Travel System

Equipped with drive motors, reducers, and travel wheels or tracks to ensure smooth movement along fermentation tanks or composting areas

Hydraulic System

Some models feature hydraulic devices that precisely adjust the height and angle of the turning mechanism to ensure turning depth and efficiency

Oxygen Supply System

Optional blower or piping systems provide adequate oxygen to compost materials, promoting microbial activity and accelerating fermentation

Intelligent Control System

Utilizes PLC or microcomputer control systems to automate operations including travel, turning, and oxygen supply

Safety Protection System

Equipped with safety devices including limit switches and emergency stop buttons to ensure operator and equipment safety

The true value of chain compost turners lies in their perfect integration of industrial-grade reliability with the specific requirements of composting processes. The chain drive design not only provides powerful power output but also ensures stable performance during long-term, high-intensity operations. Whether processing viscous livestock manure or mixing dry crop straw, this equipment consistently delivers outstanding performance.

A Key Force Driving the Green Revolution

In today’s global push for circular economy and sustainable development, chain compost turners are becoming crucial equipment for organic waste resource utilization with their exceptional performance and reliable quality. They not only solve technical challenges in large-scale composting production but also contribute significantly to organic agriculture and environmental protection through their efficient and energy-saving characteristics. From agricultural waste treatment to organic fertilizer production, from bioenergy development to environmental protection, chain compost turners are writing new chapters in green technology worldwide.

Chain Compost Turner – Driving the composting industry to new heights with chain transmission technology