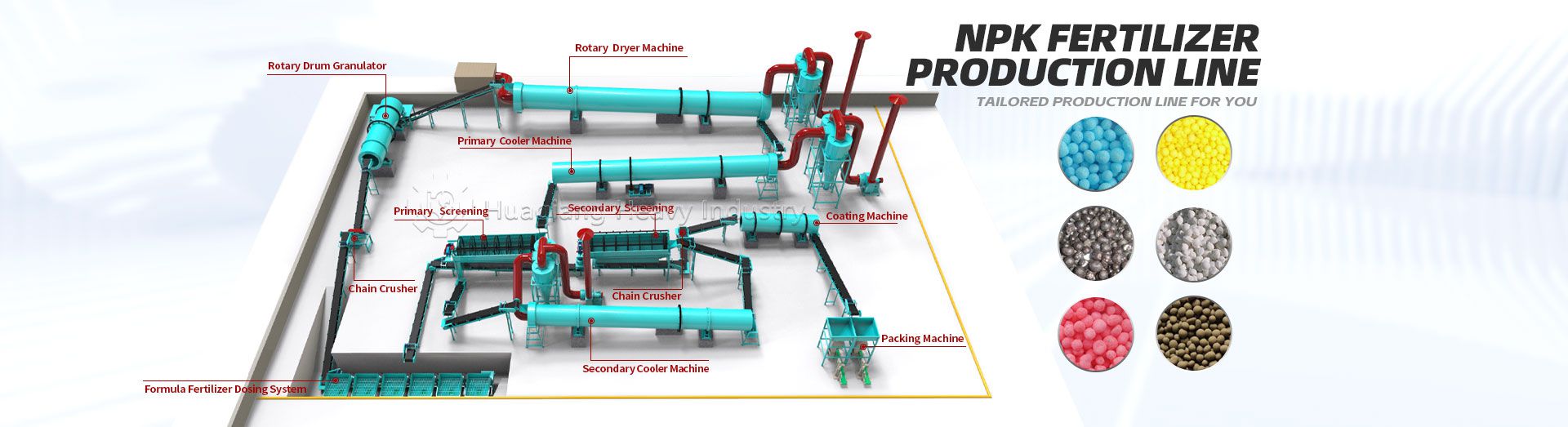

Advantages of Rotary Drum Granulators over Disc Granulators

When selecting organic fertilizer granulation equipment, both rotary drum and disc granulators are commonly used. However, rotary drum granulators, with their multi-dimensional performance advantages, better meet the efficiency and scale requirements of modern organic fertilizer production lines. The differences between the two are primarily reflected in the following four aspects.

More flexible capacity adaptability meets the needs of large-scale production. Disc granulators are limited by the diameter of their discs, typically with an hourly output of 0.5-5 tons per unit, making them suitable only for small production lines. By adjusting the drum length and diameter, rotary drum granulators can achieve hourly outputs of 1-20 tons per unit. They meet the basic production needs of small and medium-sized enterprises as well as the large-scale production of large factories. They eliminate the need for multiple units in parallel, reducing production line floor space and equipment investment costs.

They offer greater raw material compatibility and reduce pretreatment complexity. Organic fertilizer raw materials have large fluctuations in moisture and composition. Disc granulators must maintain a moisture content of 20%-30%. They also struggle with crude fiber materials, which tend to stick to the disc and produce uneven granules. Rotary drum granulators can process materials with moisture levels of 25%-40%. Leveraging the multi-directional force of the rotating drum, they can smoothly granulate composted straw, livestock manure, and other materials without the need for additional crushing or conditioning, streamlining the process.

The resulting product is more stable and meets standardized requirements. Due to the single direction of centrifugal force, disc granulators produce pellets with a roundness of 70%-80% and large particle size variations. Rotary drum granulators, on the other hand, utilize internal rollers to guide and rotate the pellets, resulting in a fully rolling and shaping process with a roundness exceeding 90% and a precisely controlled particle size of 2-5mm. Furthermore, the granulation process is gentle, does not damage organic matter, and the pellets are of moderate strength. Transportation losses are 15%-20% lower than those from disc granulators.

Operation and maintenance are also simplified, resulting in lower long-term costs. Disc granulators require frequent manual adjustments of inclination and speed, resulting in wear and tear on the disc edges and requiring frequent replacement. Rotary drum granulators, on the other hand, utilize automated control to precisely adjust speed and feed rate, eliminating the need for manual oversight. The drum is constructed of wear-resistant stainless steel, resulting in a 40% lower failure rate and over 30% lower maintenance costs, resulting in superior long-term economics.

In summary, the advantages of the rotary drum granulator in terms of production capacity, raw material compatibility, finished product quality, and cost control make it ideally suited to the diverse needs of organic fertilizer production lines, making it an ideal choice for improving efficiency and competitiveness.