Exploring the BB Fertilizer Mixer: How Does It Achieve Perfect Blending?

What is a BB Fertilizer Mixer?

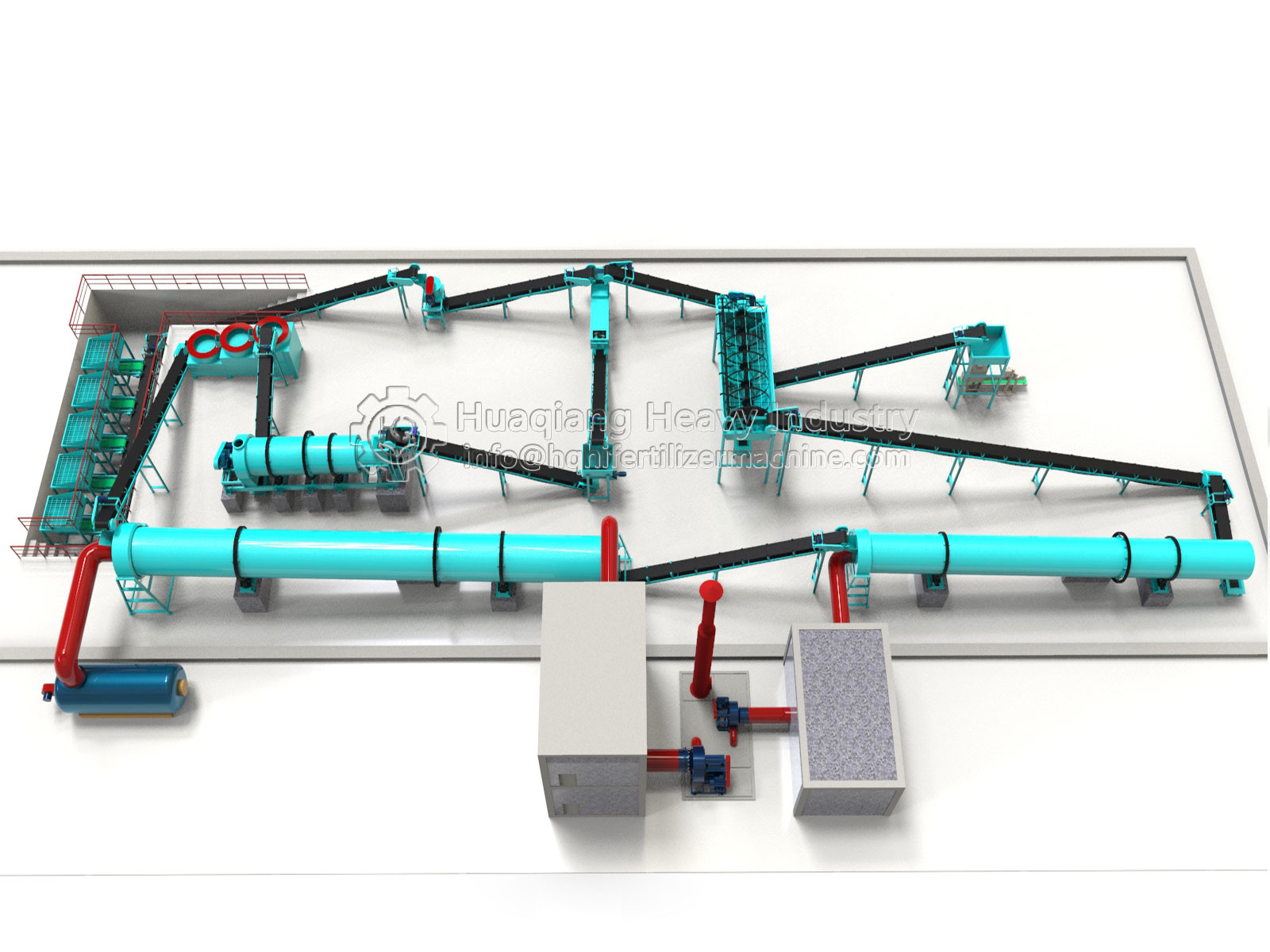

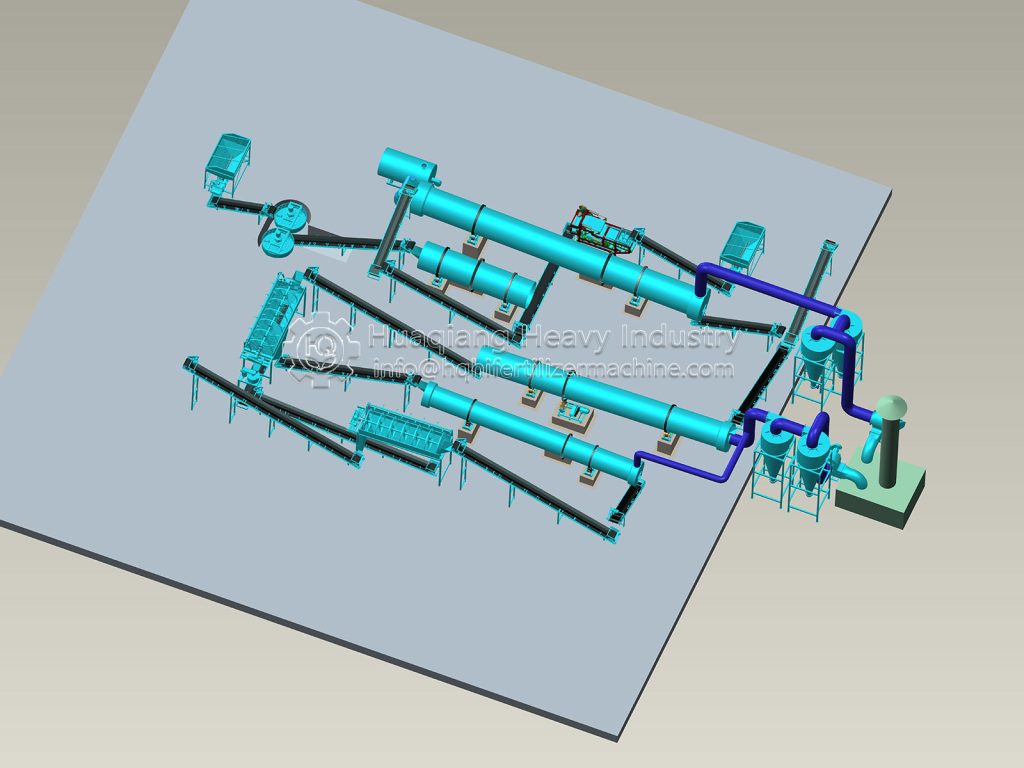

In modern agriculture, the BB fertilizer mixer plays a crucial role in the NPK manufacturing process. As an essential NPK blending machine, it physically combines different fertilizer raw materials without chemical reactions, creating balanced compound fertilizers with precise nutrient ratios.

This specialized equipment works in tandem with an NPK fertilizer granulator machine, forming a complete production line where the mixer ensures homogeneous blending before granulation. The entire NPK production process relies on this critical connection between mixing and granulating equipment to produce quality fertilizers with stable composition and optimal nutrient availability.

By ensuring uniform distribution of nutrients throughout the mixture, the BB fertilizer mixer enables the NPK fertilizer granulator machine to produce consistent granules with balanced NPK ratios, ultimately enhancing crop productivity and sustainable agricultural practices.

An efficient BB fertilizer mixer not only enhances production efficiency but also ensures consistent product quality, providing strong support for sustainable modern agriculture.

Equipment Structure and Composition

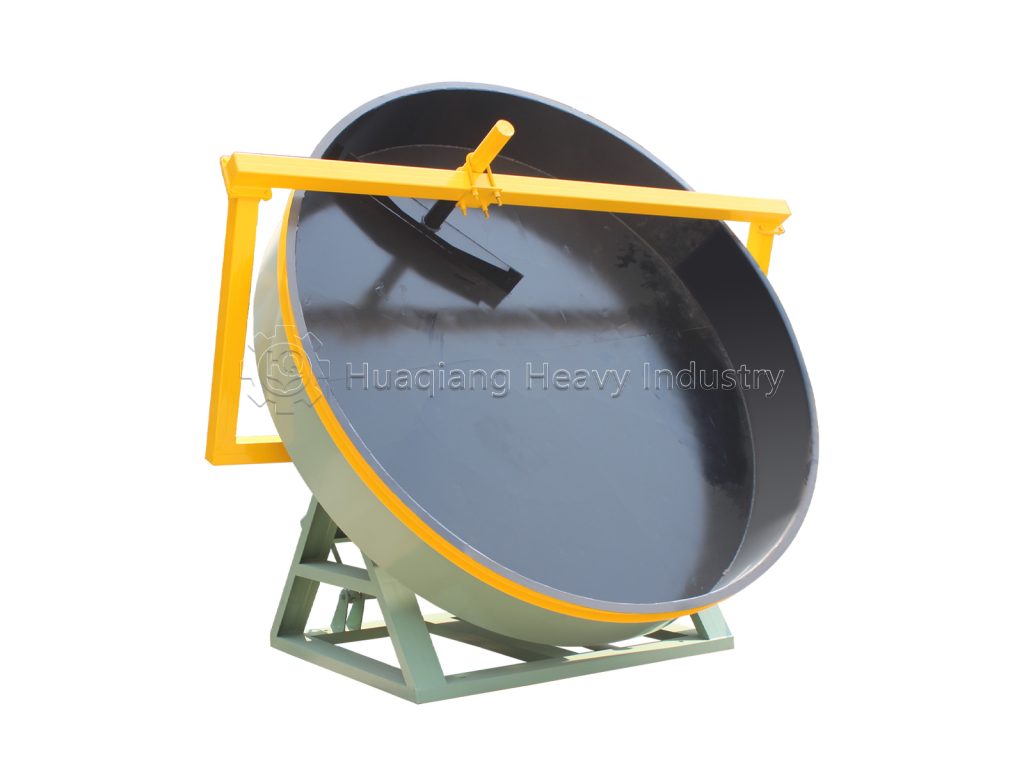

Although different models and manufacturers may vary, a typical BB fertilizer mixer usually consists of the following core components:

Mixing Drum: This is the enclosed space where the mixing process occurs, typically designed in a cylindrical or U-shape to ensure even distribution of materials during mixing.

Mixing Device: Composed of a mixing shaft and blades attached to it, common blade types include paddle-type and spiral ribbon-type, selectable based on mixing requirements.

Drive System: Includes motor and reducer, providing power for the mixing device.

Feeding and Discharging System: The feeding inlet is used to add raw materials, while the discharge outlet or valve is used to remove the mixed fertilizer.

Control System: Used to monitor and adjust parameters such as mixing speed and time, ensuring precision in the mixing process.

Support and Frame: Provides stable support for the mixer, ensuring stability during operation.

Working Principle

The working principle of the BB fertilizer mixer is based on the rotational movement of the mixing device inside the drum:

Feeding Stage: Various fertilizer raw materials are added to the mixing drum through the feeding inlet.

Mixing Stage: The motor drives the mixing shaft to rotate, and the blades shear, tumble, and diffuse the materials during rotation, achieving uniform mixing.

Discharge Stage: The uniformly mixed BB fertilizer is discharged from the outlet or valve, typically transported to packaging equipment via conveyor belts or pneumatic systems.

Equipment Features and Advantages

The BB fertilizer mixer offers several notable features:

Uniform Mixing: Specifically designed for processing fertilizer materials, ensuring even distribution of all components and production of consistent quality BB fertilizer.

High Processing Capacity: Suitable for large-scale production, capable of handling substantial quantities of fertilizer raw materials.

Relatively Simple Structure: Easy to operate and maintain, suitable for agricultural and fertilizer production environments.

Easy to Clean: The design of the mixing drum and device facilitates cleaning, preventing cross-contamination between different batches of materials.

Strong Adaptability: Capable of processing fertilizer raw materials of different properties, including solid particles and powders.

Whether for small farms or large fertilizer production enterprises, the BB fertilizer mixer is an indispensable piece of equipment for enhancing production efficiency and ensuring product quality.

.jpg)