In-depth comparison of flat die granulators and other pelletizing equipment

Comparison of Ring Die Granulators

In terms of roller design, the rollers of flat die granulators can be enlarged arbitrarily, enhancing the bearing’s pressure-bearing capacity. However, due to the limited diameter of the ring die, the rollers of ring die granulators cannot be enlarged, resulting in a smaller bearing chamber and relatively weaker pressure-bearing capacity. Regarding the mold, flat die granulators are relatively easy to replace and less expensive; while the molds of ring die granulators are complex, difficult to replace and more expensive. Regarding equipment stability, the evenly distributed rollers of flat die granulators ensure smoother operation, while ring die granulators are prone to vibration and noise during operation.

Similarities and Differences between Disc Granulators

Disc granulators form pellets by rolling the material on a rotating disc, while flat die granulators form pellets by squeezing the material between rollers and a flat die. Regarding pellet shape, disc granulators produce irregular spherical pellets, while flat die granulators produce cylindrical pellets. In terms of production efficiency, disc granulators offer higher output but relatively lower pellet strength; flat die granulators offer moderate output but higher pellet strength. In terms of applicable materials, disc granulators are more suitable for viscous materials, while flat die granulators have a wider range of applications.

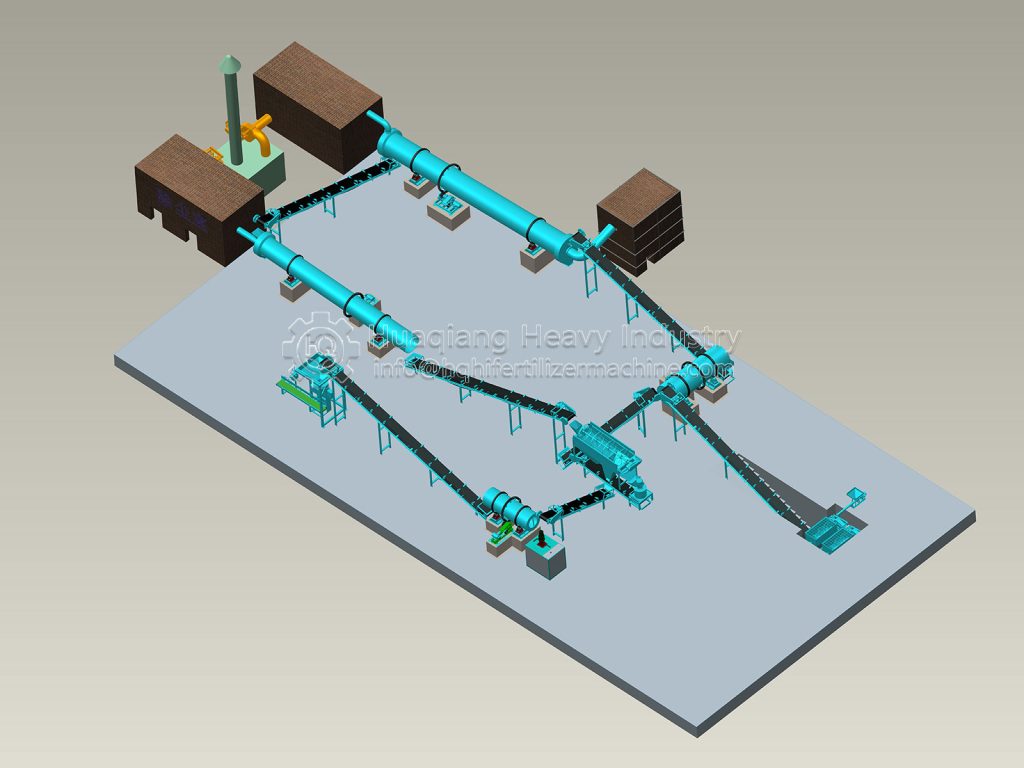

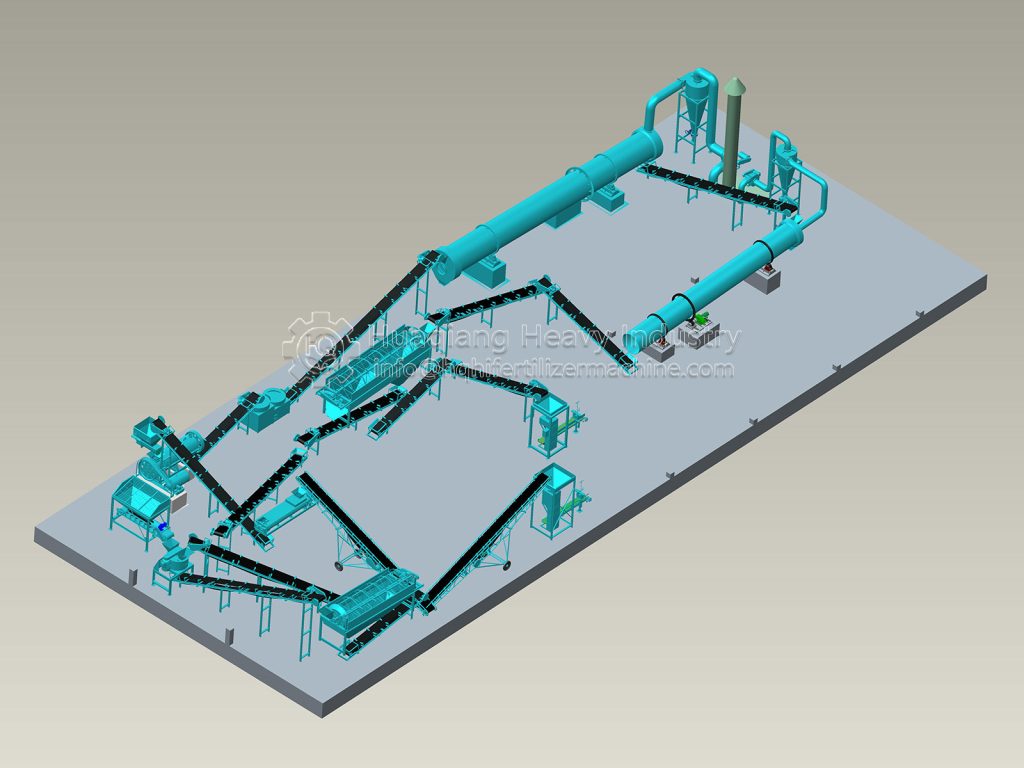

Analysis of Rotary Drum Granulators

Rotary drum granulators tumble the material in a rotating drum and spray a binder to form pellets. Their structure is relatively complex. Flat die granulators are more compact, using direct extrusion between a roller and a die to form pellets. In terms of granulation quality, rotary drum granulators produce pellets with irregular shapes and uneven sizes, while flat die granulators produce pellets with regular shapes and uniform sizes. In terms of energy consumption, rotary drum granulators consume relatively high energy due to their large size and numerous operating parts, while flat die granulators consume less energy.